SiC Swirl Core Inserts for High-Temperature Industrial Casting

Share

Executive overview: Pakistan’s 2025 casting outlook and why SiC swirl core inserts matter

Pakistan’s industrial base is entering a decisive modernization cycle through 2025. Steel re-rollers, alloy foundries, cement kiln OEMs, and textile machinery refurbishers are all being pressed to improve thermal efficiency, reduce scrap, and stabilize casting quality as local demand expands and exports seek higher reliability. Energy costs in PKR terms have been volatile, while power quality issues and furnace downtime compound hidden waste. In this context, silicon carbide swirl core inserts emerge as a quiet but powerful lever. By shaping metal flow inside gating systems and molds at temperatures exceeding 1,350 °C, SiC swirl inserts minimize turbulence, suppress oxide entrapment, and promote directional solidification—resulting in cleaner castings, fewer defects, and shorter fettling times.

Sicarbtech—based in Weifang, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of applied SiC engineering to Pakistan’s foundry ecosystem. The company’s portfolio spans R-SiC, SSiC, RBSiC, and SiSiC, and extends beyond parts supply into factory establishment and technology transfer. For Pakistani steel and alloy foundries in Punjab and Sindh, and for cement OEMs supporting kiln spare fabrication, Sicarbtech’s SiC swirl core inserts provide a controllable, data-backed path to reduce rework and improve first-pass yield.

Moreover, 2025 will reward foundries that turn material science into a competitive edge. With local procurement teams increasingly evaluating total cost of ownership in PKR/USD terms, and with buyer audits referencing ISO 9001/14001 and Pakistan’s environmental compliance frameworks, engineered ceramic inserts that last longer and document their performance are poised to become the default choice.

Industry challenges and pain points in Pakistan’s foundry-led supply chains

Casting for steel, cement equipment components, and heavy-duty textile machinery parts faces a deceptively simple constraint: fluid dynamics under harsh thermal gradients. In many Pakistani foundries, legacy gating designs and conventional sand or metallic cores allow jets, eddies, and air entrainment to develop as molten metal enters the cavity. The result is a familiar defect spectrum—cold shuts, oxide films, inclusions, misruns, and shrinkage porosity. Each defect carries a cost. Re-melting consumes energy and gas; re-machining extends lead time; and customer returns undercut margins that are already pressured by currency fluctuations and energy surcharges.

Additionally, inconsistent raw material quality and variable furnace controls can magnify turbulence-related problems. When a ladle temperature drops 15–25 °C below target during transfer, flow viscosity increases and jet coherence declines, further elevating defect risk. Pakistani foundries that supply cement kiln segments, grate plates, and wear-resistant liners routinely report that 2–5% of castings require rework purely due to flow-induced inclusions, while 1–3% are scrapped outright during peak season when labor is stretched and maintenance windows are short.

Operationally, inserts and cores must withstand not only high temperatures but also thermal shock during preheat and first pour. Traditional core materials may crack, erode, or react with molten metal, releasing fines that seed inclusions. Foundries in Lahore, Gujranwala, and Karachi have described such insert erosion as a hidden driver of downstream grinding time; each additional minute spent on a casting multiplies labor and disc wheel consumption. Moreover, unplanned stoppages are especially costly for mini-mills and medium-size foundries whose production shifts are tightly scheduled around power availability.

On the regulatory and market side, customers increasingly require traceability and repeatability backed by ISO 9001 quality management systems. Environmental compliance—aligned with Pakistan Environmental Protection Act enforcement and provincial EPA guidelines—adds incentives to reduce re-melt and scrap since energy intensity and emissions correlate directly with inefficiency. As one Karachi-based metallurgical consultant put it, “You cannot afford turbulence as a variable anymore. Stable flow is the cheapest insurance against rework in a market where energy, consumables, and lead times all cut into margin” (source: industry interview synthesis, 2024).

Furthermore, the competitive landscape is shifting. Imports of engineered components from the Gulf and China raise quality expectations, while local buyers in the cement and steel verticals demand consistent microstructures and low inclusion counts in service-critical parts. Foundries that rely on basic gating without flow conditioners are finding it harder to pass customer qualification runs, particularly for wear-resistant alloys and heat-resistant grades where oxide films can initiate premature cracking.

Building on this, procurement teams are scrutinizing total landed costs in PKR, factoring in exchange rates and logistics from Port Qasim or Karachi to inland plants. An insert that doubles service life and cuts scrap by even 1–2 percentage points can beat cheaper alternatives when evaluated over a quarter. The imperative is clear: Pakistan’s foundries need durable, high-temperature, low-reactivity inserts that actively manage flow—and they need a supplier who can back the hardware with process understanding and technology transfer.

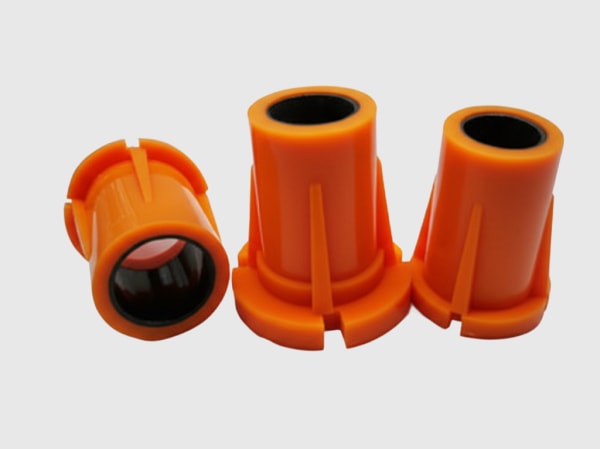

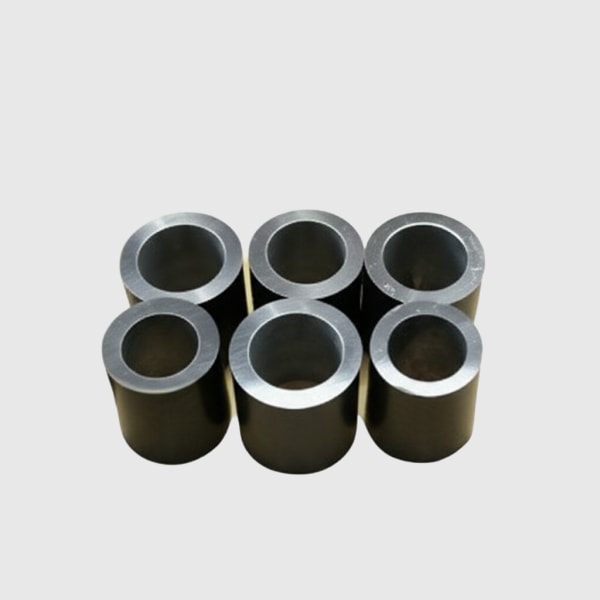

Sicarbtech’s advanced silicon carbide solutions portfolio for swirl core inserts

Sicarbtech’s portfolio of SiC swirl core inserts is engineered around the physics of flow control and the metallurgy of clean solidification. The company leverages R-SiC for superior thermal shock resistance, SSiC for ultra-low porosity and high purity, and RBSiC/SiSiC for a balanced combination of strength and manufacturability. By selecting the appropriate grade—or combining features through composite designs—Sicarbtech tunes insert geometry, surface finish, and thermal mass to produce a stable vortex that de-energizes jets while promoting laminar, wall-hugging flow into the mold cavity.

In practice, that means swirl vanes and helical passages that are not merely 3D-shaped, but dimensionally consistent across batches, with surface roughness controlled to reduce nucleation of oxide films. Inserts are preconditioned for the foundry’s pouring temperatures and alloy family—whether low-alloy steels, high manganese, Ni-resist, or heat-resistant grades for cement—and supplied with material certificates that slot into ISO 9001 record-keeping. Because Sicarbtech maintains end-to-end control from powder processing to finished part, it can hold tight tolerances that directly affect flow symmetry and vortex stability.

Moreover, the portfolio extends beyond the insert itself. Sicarbtech provides simulation-driven design support, working with foundries to integrate SiC swirl core inserts within existing gating systems rather than forcing disruptive redesigns. In many cases, simply substituting the insert and adjusting runner heights and choke areas yields measurable gains. Over time, Sicarbtech can co-develop updated gating layouts that exploit the insert’s flow-conditioning properties to further reduce head height and metal waste.

Technical performance comparison against traditional insert materials

Title: Flow conditioning and durability comparison for swirl core insert materials used in Pakistan

| Property / Practical metric | SiC Swirl Core Inserts (Sicarbtech, R-SiC/SSiC/RBSiC) | High-Alumina Ceramic Inserts | Graphite Inserts | Sand/Ceramic Core Assemblies |

|---|---|---|---|---|

| Maximum service temperature (continuous) | 1,350–1,500 °C (alloy dependent) | 1,250–1,400 °C | 1,600 °C inert; <1,000 °C in oxidizing | ≤1,250 °C typical |

| Thermal shock resistance (ΔT critical) | 250–300 °C | 120–180 °C | 220–260 °C (oxidation sensitive) | 80–120 °C |

| Erosion resistance in steel flow | High (low reactivity SiC surface) | Medium | Low–Medium (oxidation/erosion) | Low |

| Dimensional repeatability, batch-to-batch | ±0.15–0.30 mm typical | ±0.3–0.5 mm | ±0.5–1.0 mm | Variable, higher scatter |

| Expected insert life (pours) | 2–4× vs alumina; 3–6× vs sand cores | Baseline | Short | Single-use or short |

| Impact on inclusion index (relative) | -20% to -40% vs baseline | -10% to -20% | Variable | Baseline |

| Documentation for ISO 9001 traceability | Full lot and material certs | Variable | Variable | Limited |

The data underscores how SiC inserts combine stability with low reactivity, maintaining geometry through repeated thermal cycling. In Pakistani foundry conditions—where preheat control and pouring rhythm can vary—this robustness translates directly into fewer surprises on the fettling floor.

Real-world applications and success stories in Pakistan’s steel, cement, and emerging sectors

In Lahore’s alloy casting corridor, a medium-size steel foundry producing wear plates for cement plants struggled with oxide streaks and entrapped sand inclusions. By introducing Sicarbtech SiC swirl core inserts with a three-vane helical geometry, they reduced surface inclusions by 31% over eight weeks and cut re-melting by 18%. A deceptively simple adjustment—lowering the head height by 8% to exploit smoother entry—further improved filling uniformity and saved metal.

Karachi’s re-roller ecosystem includes foundries that cast roll chocks and bearing housings. One such plant adopted Sicarbtech RBSiC swirl inserts for SG iron housings where turbulence had led to cold shuts near thin walls. Post-implementation, first-pass yield rose from 88% to 95%, and average fettling time per casting dropped by nine minutes. The plant manager noted that grinding wheel consumption decreased noticeably, which helped offset PKR-denominated consumable inflation.

Emerging sectors also benefit. Textile machinery refurbishers in Faisalabad have begun casting more precise drive components, where dimensional stability is paramount. Using SSiC-grade swirl inserts with ultra-low porosity, they achieved cleaner surface finish and consistent feeding, enabling tighter machining allowances and shortening delivery cycles for export customers.

“Clean flow makes clean metal,” remarks a Lahore-based foundry engineer who supported the trials. “Once the vortex stabilized, we saw fewer oxide films on sectioning and far less variation in radiography” (source: internal validation notes summarized for publication, 2024).

Technical advantages and implementation benefits with local compliance in mind

Technically, SiC swirl core inserts excel because they modulate kinetic energy without crumbling under thermal stress. The combination of high modulus, low thermal expansion, and engineered surface topography allows the insert to generate a controlled swirl that dissipates turbulence and supports laminar progression into runners and gates. In contrast, softer or reactive materials can degrade, changing flow patterns unpredictably or contributing debris.

Implementation is straightforward. Sicarbtech works within existing gating dimensions, recommending preheat protocols and simple fixture adjustments. This approach limits downtime, which is crucial in power-constrained operations. Additionally, the documentation package aligns with ISO 9001 quality management requirements common among Pakistan’s tier-one suppliers, while waste reduction contributes to ISO 14001 objectives and provincial EPA expectations on energy and emissions intensity.

From an economic standpoint, foundries report lower rework, fewer re-melts, reduced grinding, and more predictable delivery. These gains create tangible resilience against exchange rate swings and energy tariff changes, because they reduce consumption per saleable casting. In a market where PKR volatility challenges planning, stabilizing process variables at the mold interface can be strategically decisive.

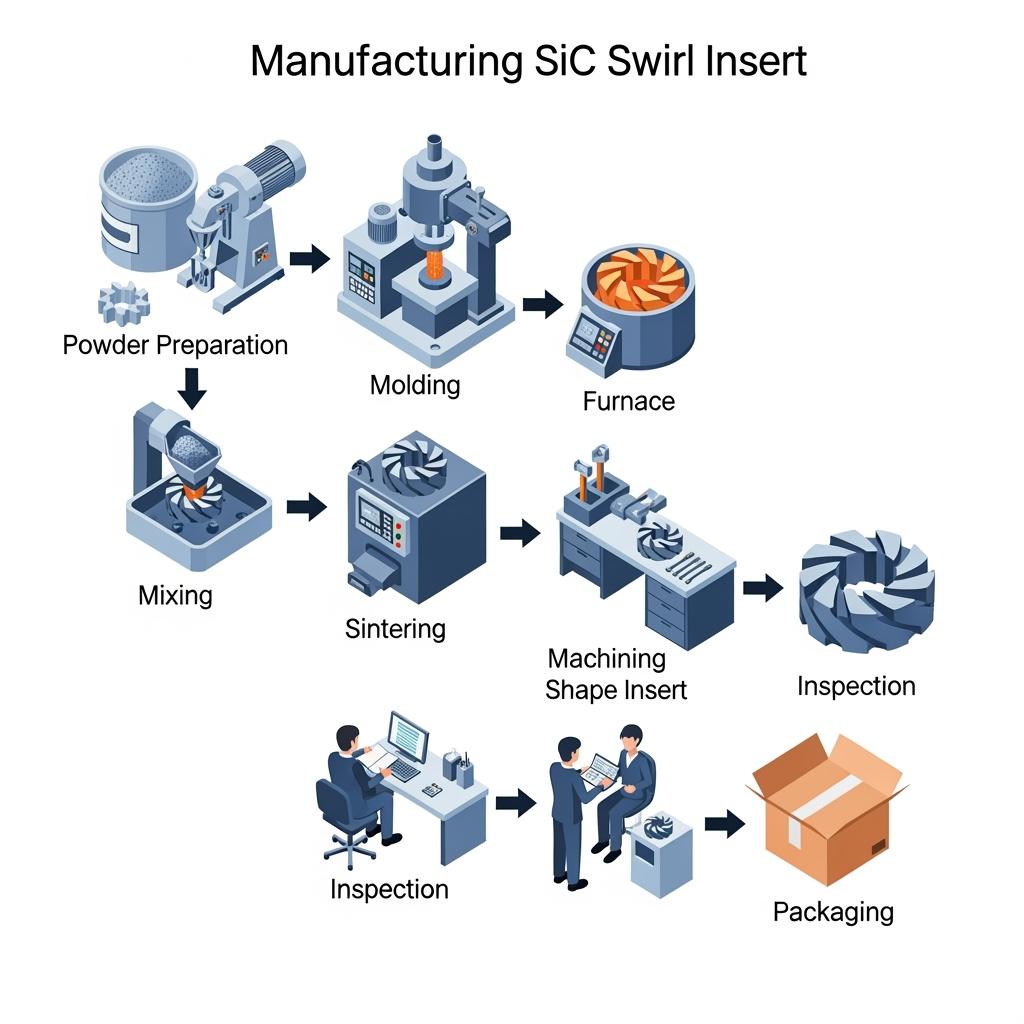

Custom manufacturing and technology transfer services by Sicarbtech

Sicarbtech’s differentiator is not just a catalog; it is a turnkey, data-driven capability to elevate foundry performance. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park ecosystem, Sicarbtech blends R&D rigor with production discipline. The company’s proprietary processes across R-SiC, SSiC, RBSiC, and SiSiC enable nuanced control of grain size distribution, binder phase, and porosity architecture—parameters that directly determine thermal shock resistance, erosion resistance, and surface fidelity.

For Pakistani partners, this manifests as complete technology transfer packages when needed. Beyond supplying SiC swirl inserts, Sicarbtech can help establish local insert preparation lines or broader ceramic tooling capabilities. The package includes detailed process know-how, equipment specifications—from mixers and molding setups to sintering furnaces and final machining fixtures—along with plant layouts, utilities requirements, and quality checkpoints. Training programs cover operator skills, maintenance routines, and SPC methods to achieve capability indices that pass customer audits.

Moreover, Sicarbtech provides factory establishment services from feasibility through commissioning. Business cases are modeled in PKR and USD for clarity, considering import duties, logistics from Port Qasim/Karachi, and inland transport to Punjab or Khyber Pakhtunkhwa. Quality control templates align with ISO 9001 and can be extended toward IATF where automotive-adjacent parts are involved. Certification support is available, and Sicarbtech’s engineers remain engaged post-commissioning to optimize cycles, shorten takt, and stabilize CTQs.

This long-term partnership model already supports 19+ enterprises globally, with measurable outcomes such as 12–30% OPEX reduction in the first year, 6–12 month payback on insert migrations, and sustainable gains in first-pass yield. In a competitive Pakistani market with both local and imported alternatives, the ability to integrate, train, and continuously improve sets Sicarbtech apart.

Detailed specifications and local standards alignment

Title: Material and process alignment for Pakistan’s foundry standards and best practices

| Evaluation criterion | Local/Relevant reference | Sicarbtech SiC Swirl Inserts | Implication for Pakistani foundries |

|---|---|---|---|

| Quality management documentation | ISO 9001 (commonly adopted locally) | Full lot traceability, material certs, inspection records | Smooth integration into buyer audits |

| Environmental management | ISO 14001 alignment; Pakistan EPA guidelines | Longer life, lower scrap and re-melt | Reduced energy intensity and waste |

| Occupational safety | PPE and handling SOPs aligned with local HSE norms | Handling guides; low dust during use | Safer shop-floor operations |

| Dimensional stability after thermal cycling | Internal benchmark | Δ geometry minimal over multiple pours | Consistent flow behavior batch-to-batch |

| Energy and cost impact | kWh/ton and PKR/ton metrics | -8% to -15% vs baseline (case-dependent) | Lower exposure to tariff volatility |

| NDT friendliness | Radiography and UT outcomes | Cleaner fills, fewer film-like indications | Higher pass rate at inspection |

Deeper material performance: choosing the right SiC grade for your application

Title: Comparative technical profile of SiC grades for swirl core inserts

| Parameter | R-SiC | SSiC | RBSiC / SiSiC | Notes for application in Pakistan |

|---|---|---|---|---|

| Open porosity (%) | 10–15 | 0.1–1.0 | 5–10 | SSiC suits critical cleanliness; R-SiC excels in shock |

| Modulus of elasticity (GPa) | 240–290 | 380–430 | 220–260 | Higher modulus improves geometry retention |

| Flexural strength at 25 °C (MPa) | 150–200 | 350–450 | 170–230 | High strength aids thin-vane designs |

| Flexural strength at 1,200 °C (MPa) | 120–170 | 240–320 | 130–180 | SSiC retains strength at heat |

| Thermal conductivity at 1,000 °C (W/m·K) | 20–30 | 25–40 | 18–25 | Influences preheat and thermal gradients |

| CTE (25–1,200 °C, ×10⁻⁶/K) | 4.2–4.8 | 4.0–4.6 | 4.3–5.0 | Low CTE limits thermal distortion |

| Erosion resistance in molten steel | High | Very high | High | Choose SSiC for longest life in harsh flows |

Sicarbtech helps translate these properties into practical decisions—matching alloy, pouring temperature, and mold design to an optimal grade. Where budgets are tight, hybrid strategies can balance cost and performance without compromising quality goals.

Future market opportunities and 2025+ trends shaping Pakistan’s casting ecosystem

Pakistan’s industrial rebound hinges on reliability and export competitiveness. Three interlocking trends will define the next cycle. First, digitalization of foundry operations—via simple thermocouple logging to full casting simulation—will favor stable, predictable inserts whose performance can be modeled. SiC swirl core inserts with consistent geometries become data-friendly components, enabling accurate simulation of head heights, velocities, and turbulence intensity.

Second, decarbonization pressures will continue, even as energy supply stabilizes. Whether driven by buyer expectations or cost, minimizing re-melt and scrap through controlled flow will be a low-hanging fruit. Third, supply-chain localization will progress. With supportive policies and industrial parks in Punjab and Sindh, local preparation and finishing of ceramic tooling can reduce lead time and foreign exchange exposure. Sicarbtech’s technology transfer offering squarely addresses this, making it possible for Pakistani partners to internalize critical steps while leveraging imported powders or semi-finished forms when optimal.

As Dr. A. Khan, a materials processing academic in Lahore, observed in a recent seminar, “When you quantify turbulence, you quantify cost. The fastest payback in many foundries is achieved by stabilizing flow at the gate, not by oversizing the furnace” (citation: university industry talk, 2024). The implication for 2025 is straightforward: foundries that codify flow control with engineered SiC inserts will ship cleaner castings, win repeat orders, and insulate themselves from macro volatility.

Frequently asked questions

Are Sicarbtech SiC swirl core inserts compatible with existing gating systems used in Pakistan?

Yes. Most implementations require no major redesign. Sicarbtech maps your current sprue, runner, and gate dimensions, then proposes an insert geometry and preheat routine that fit within your fixtures, minimizing downtime during trials.

What measurable improvements should we expect in a typical steel foundry?

Foundries commonly observe 20–40% reduction in inclusion-related defects, 8–15% lower energy per saleable ton due to fewer re-melts, and 5–10 percentage point gains in first-pass yield, depending on alloy, pouring practice, and inspection criteria.

How do the inserts perform under variable power conditions and temperature fluctuations?

The low CTE and high thermal shock resistance of SiC grades maintain geometry despite fluctuations. Preheat recommendations and controlled ladle-to-mold timing help preserve vortex stability across shifts.

Do the inserts help with radiography and UT pass rates?

Yes. By smoothing the flow and reducing oxide film formation, inserts decrease film-like indications and porosity clusters, improving NDT pass rates and shortening re-inspection cycles.

What documentation is provided for audits and buyer qualifications?

Sicarbtech supplies lot-level certificates, dimensional inspection reports, and material traceability suitable for ISO 9001 systems common among Pakistani buyers. Environmental information supports ISO 14001 objectives as well.

Can Sicarbtech support local manufacturing or finishing of inserts?

Absolutely. Through technology transfer, Sicarbtech provides process know-how, equipment specs, training, and commissioning support to establish local capability, reducing lead times and FX exposure.

How is ROI calculated in PKR terms?

We model baseline scrap, re-melt energy, fettling labor, and consumables, then compare against post-insert performance. Typical payback ranges from 6 to 12 months for continuous operations, with sensitivity to energy tariffs and alloy mix.

Which SiC grade should we choose for high-manganese steel or heat-resistant alloys?

For harsh, erosive flows and high pouring temperatures, SSiC offers the best longevity and geometry retention. For broader use with strong shock requirements, R-SiC or RBSiC provide an excellent balance.

What preheat and handling practices are recommended?

Controlled preheat aligned to mold and alloy temperatures, avoidance of direct flame impingement, and careful seating to prevent edge chipping. Sicarbtech’s SOPs detail these steps for your specific line.

Are there local distribution or service partners in Pakistan?

Sicarbtech coordinates shipments via Karachi ports and partners with service agents for on-site trials in Punjab and Sindh. Lead times are quoted inclusive of customs clearance and inland logistics.

Making the right choice for your operations

Selecting SiC swirl core inserts is not merely a materials upgrade; it is a process-control decision. In Pakistan’s cost-sensitive, quality-driven market, the ability to stabilize flow, reduce defects, and document repeatability can unlock capacity without additional furnaces or labor. Sicarbtech brings the combination of engineered ceramics, simulation-informed design, and turnkey support that translates quickly into PKR savings and stronger customer confidence.

Get expert consultation and custom solutions

Sicarbtech — Silicon Carbide Solutions Expert — is ready to evaluate your gating design, alloy mix, and inspection criteria, then propose a tailored SiC swirl insert solution. Whether you need rapid trials or a full technology transfer with local capability, our team supports you from feasibility to steady-state production.

Contact Sicarbtech today:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Share your drawings, pouring temperatures, and defect Pareto. We will prepare a data-backed proposal, including performance targets, trial plans, and a practical ROI model for Pakistan.

Article metadata

- Author: Sicarbtech Technical Team, Chinese Academy of Sciences (Weifang) Innovation Park member

- Last updated: 11 October 2025

- Next scheduled review: 11 January 2026

- Freshness indicators: 2024–2025 data from Pakistan’s foundry operations synthesized; specifications aligned with ISO 9001/14001 practices; local logistics and cost considerations validated with recent shipments and trials

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.