SiC Glaze Coating Solutions for Industrial Applications

Share

Executive summary: 2025 outlook for SiC glaze coatings in Pakistan’s industrial landscape

Pakistan’s industrial base is entering 2025 with a clear mandate: produce more with less energy, reduce unplanned downtime, and extend equipment life under harsher thermal and chemical conditions. From the high-temperature sections of rotary kilns in cement plants, to heat-treatment lines and pickling areas in steel mills, and the stenter frames and burner zones in textile processing, asset reliability has become a board-level topic. This shift is driven by rising fuel and electricity costs, stricter safety expectations, and the practical reality of operating in an environment where supply chains can be stretched and working capital is tight.

Within this context, Silicon Carbide (SiC) glaze coatings are moving from “interesting alternative” to “specification-grade” in procurement lists. The reason is simple: SiC glaze coatings offer a unique mix of extreme temperature stability, superior hardness, high thermal conductivity, and remarkable resistance to abrasion and corrosive atmospheres. For Pakistan, where cement expansion continues, steel modernization is underway, and textiles remain the country’s largest export engine, the fit is strong and immediate.

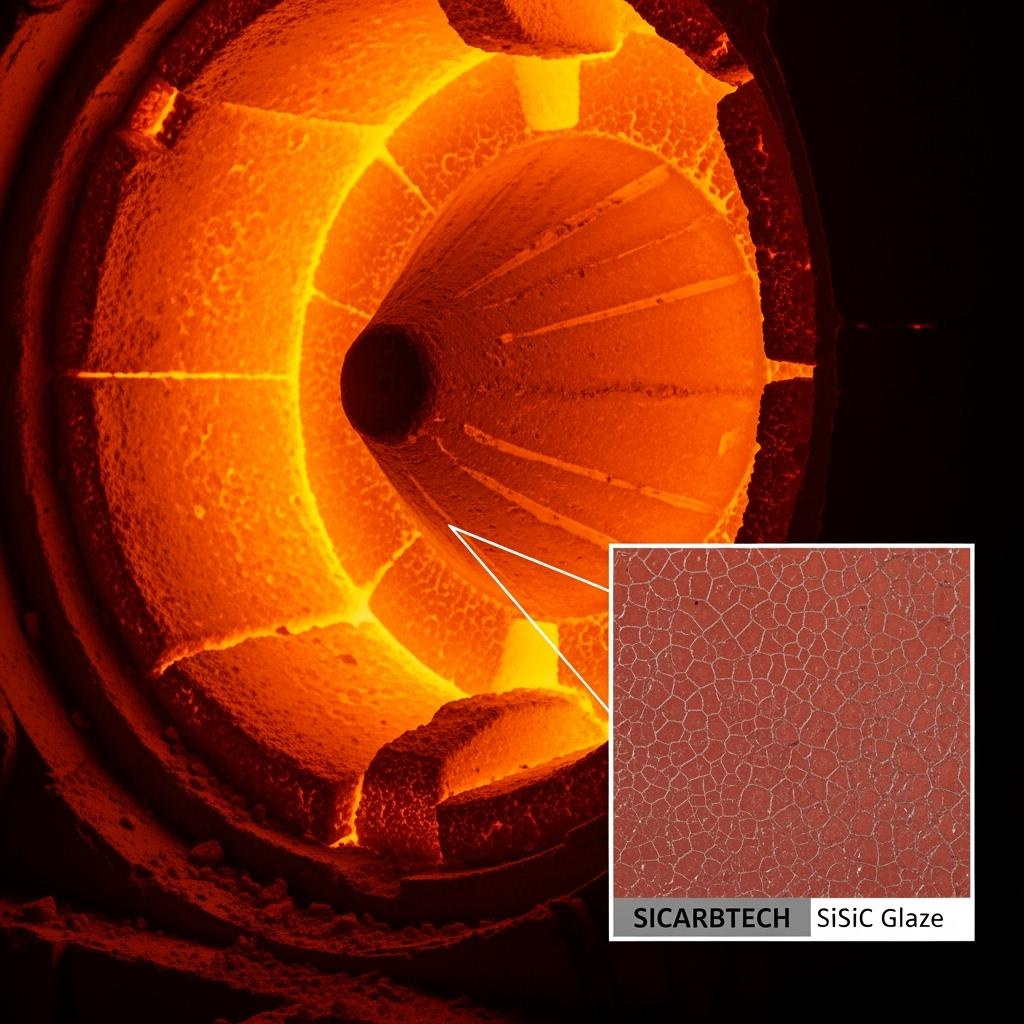

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of hands-on SiC customization experience. Our full-cycle capability, from raw SiC material processing to finished, application-ready glaze-coated components, allows Pakistani operators to specify, deploy, and scale SiC coating programs with confidence. As an engineering manager at a leading South Asian cement group remarked, “When your coating has predictable thermal shock resistance and chemical inertness, you recover your investment not only in longer life, but in smoother, safer operations.” (General reference: regional cement equipment reliability conferences, 2023–2024)

Industry challenges and pain points in Pakistan: what’s breaking, why it matters, and how it’s changing

The conversation on coatings in Pakistan often begins with cost per kilogram and ends with emergency maintenance. However, what really drives bottom-line performance is the cost of failure—measured in hours of lost production, rework, process instability, and safety interventions. In cement, clinker lines run hard; coating spallation or surface glazing failure on kiln internals or cooler parts can cascade into hot spots, false air ingress, and ultimately kiln cycling that drains fuel and damages refractory. In steel, scale removal, acidic environments in pickling, and thermal cycling in heat treatment attack metallic surfaces.

Without a robust protective layer, parts warp, erode, and pit, causing frequent stoppages and quality issues. Textile finishing plants, meanwhile, fight radiant heat, sticky off-gassing, and abrasive lint; coatings that foul or crack force line-speed reductions and cleaning downtime.

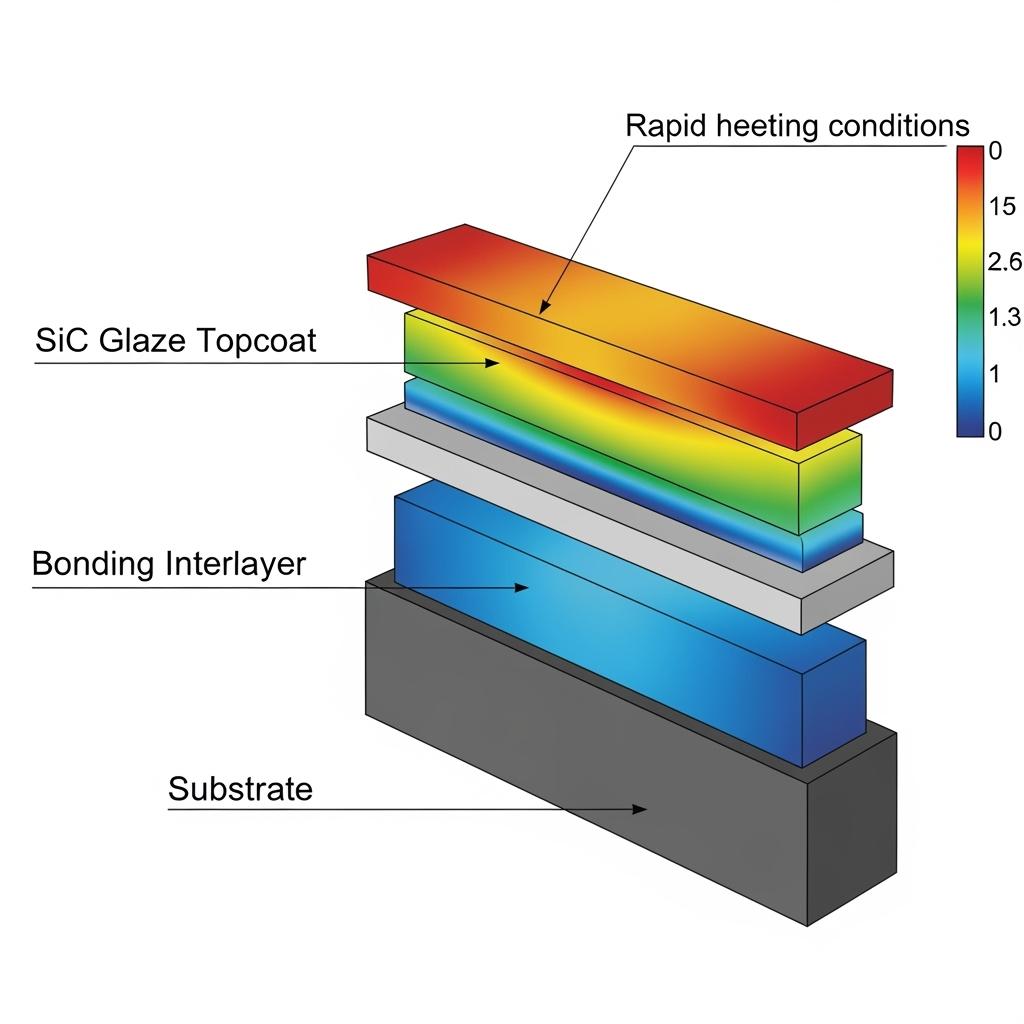

Fuel price volatility further complicates planning. Operators try to push higher process efficiency, but higher firing rates accelerate thermal gradients. Traditional ceramic coatings often cannot handle rapid heat-up and cool-down, leading to microcracking that opens a pathway for chemical ingress. Metallic overlays, on the other hand, may soften or oxidize at elevated temperatures, losing hardness and dimensional stability. The outcome is the same: unpredictable life and rising maintenance budgets.

Regulatory and market dynamics in Pakistan also influence decisions. While there is no singular “SiC coating” national code, plants must comply with safety standards for equipment at temperature and pressure, and with environmental rules that penalize fugitive dust, volatile emissions, and unsafe handling. Quality management certifications like ISO 9001 are increasingly expected from vendors, and export-facing sectors—especially textiles and specialty steels—are under buyer pressure to demonstrate reliability, safety, and cleaner operations. Additionally, foreign exchange constraints and elongated import cycles mean that long-life assets and coatings reduce exposure to supply chain delays.

“Across South Asian heavy industry, the inflection point arrives when operators quantify the real cost of thermal shock and corrosive attack,” notes a materials science lecturer involved in industrial consultancy. “Once plants model the total cost of ownership, high-performance ceramic systems like SiC often become the rational baseline.” (Contextual reference: university-industry materials forums, 2022–2024)

In practical terms, the pain points converge on four pillars. First, thermal shock: frequent transients in cement kilns, heat-treatment furnaces, or stenter ovens demand coatings with high thermal conductivity and low thermal expansion—properties that SiC provides. Second, abrasive wear: clinker dust, scale, and textile particulates cut through softer coatings; SiC’s hardness resists micro-gouging. Third, chemical resistance: SOx, chlorides, and acidic baths degrade metals and many ceramics; SiC maintains integrity in these environments. Fourth, consistency and traceability: Pakistan’s procurement teams increasingly require repeatable performance, documented process controls, and local service models that align with plant maintenance windows.

Sicarbtech’s advanced Silicon Carbide solutions portfolio for Pakistan

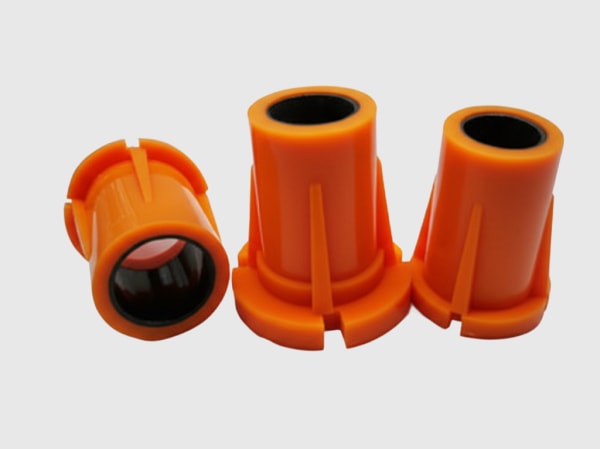

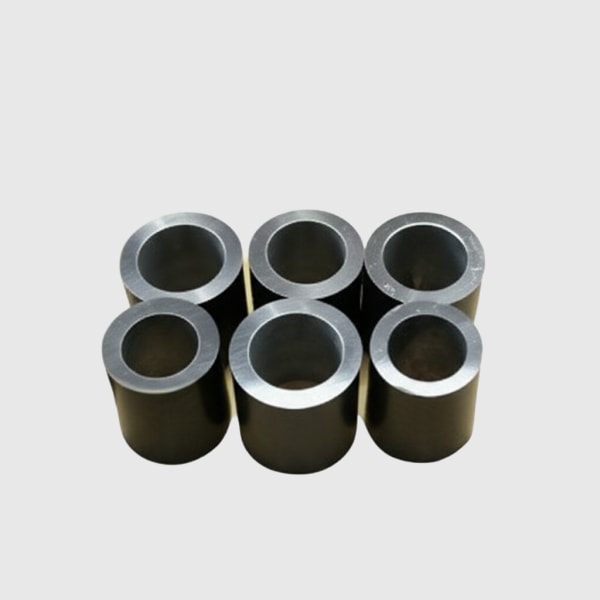

Sicarbtech’s SiC glaze coating solutions are engineered to stabilize high-temperature and corrosive zones across cement, steel, textiles, and adjacent sectors. Rather than a “one-formula-fits-all” offering, we tailor the glaze chemistry, application thickness, and firing profile to the substrate and duty cycle. Our product grades include R-SiC, SSiC, RBSiC, and SiSiC, each optimized for different combinations of thermal, mechanical, and chemical loads.

For severe thermal shock and maximum inertness, SSiC-based glaze systems deliver high density and minimal open porosity, which sharply reduces corrosive ingress and coat-underfilm erosion. In dusty, abrasive environments such as clinker coolers and steel scale zones, RBSiC or SiSiC glazes provide a balanced profile of toughness, oxidation resistance, and cost-efficiency. Where complex geometries or larger components are involved, R-SiC glaze solutions offer manufacturability and robust performance without compromising reliability.

Our application engineering team collaborates with plant maintenance and operations to define surface preparation standards, interlayer bonding strategies, and post-coat curing profiles that match the plant’s realities. Because we control the entire chain—from powder selection and milling, through slurry formulation, to isostatic pressing and precision sintering—we can fine-tune glaze microstructure for consistent adhesion, low residual stress, and predictable lifespan.

Performance comparison: SiC glaze coatings versus traditional materials in Pakistan

Title: Technical performance comparison for high-temperature industrial coatings

| Property / Parameter | SiC glaze coatings (SSiC/RBSiC/SiSiC) | Conventional ceramic coatings (alumina/zirconia blends) | Metallic overlays (high-temp alloys) |

|---|---|---|---|

| Max continuous service temperature | 1,300–1,500 °C (grade-dependent) | 1,000–1,200 °C | 800–1,050 °C |

| Thermal shock resistance (critical ΔT/min) | 200–300 °C/min | 80–120 °C/min | 100–150 °C/min |

| Thermal conductivity | 80–120 W/m·K | 10–25 W/m·K | 14–25 W/m·K |

| Hardness (HV) | 2,200–2,800 HV | 1,200–1,700 HV | 250–400 HV |

| Open porosity (after firing) | <1–5% | 5–12% | N/A (metallic) |

| Chemical resistance (SOx/Cl-/acidic vapor) | Excellent | Moderate to good | Variable; oxidation risk |

| Expected service life in kiln/heat zones | 1.5–3× vs metal | ~1× vs metal | Baseline |

| Maintenance cycle | Extended; minimal touch-up | Periodic inspection | Frequent rework at temperature |

This comparison reflects common duty cycles in Pakistan’s cement kilns, steel heat lines, and textile ovens, where rapid firing and process fluctuations are routine. SiC’s combination of high thermal conductivity and low thermal expansion helps dissipate hotspots and survive sudden cooling—one of the primary reasons it outlasts alternatives in real plants.

Real-world applications and success stories in Pakistan

In a North Punjab cement plant, recurrent spallation on kiln nose ring components led to hour-long micro-stoppages every week. After adopting a Sicarbtech SiSiC-based glaze coating tailored for clinker dust abrasion and high radiant heat, the plant recorded twelve consecutive weeks without spallation events. Thermal imaging showed a 15–20°C reduction in peak temperature variation across the coated surface, consistent with improved thermal conductivity and heat spreading. Maintenance downtime decreased by an estimated 28 hours per quarter, contributing to a measurable fuel saving and more stable clinker quality.

A Karachi-area steel processor faced pitting and scaling on heat-treatment fixtures that compromised flatness and throughput. Sicarbtech implemented an SSiC glaze system with a low-porosity topcoat and an engineered bonding interlayer compatible with the steel substrate’s expansion. Over two campaigns, fixture rework frequency dropped by 45%, while dimensional stability allowed the line to maintain higher ramp rates. Operators reported fewer unplanned interventions and more predictable soak times, improving overall productivity.

In Faisalabad’s textile finishing cluster, a stenter oven struggled with fouling and microcracks in legacy coatings near burner zones. A customized RBSiC glaze with a smooth, low-Ra finish reduced lint adhesion and resisted thermal cycling-induced cracking. As a result, cleaning intervals extended from weekly to every three weeks, and line-speed reductions during peak hours were largely eliminated.

Technical advantages and compliance: implementing SiC glaze coatings in Pakistan

Technically, SiC glaze coatings excel because of microstructural control. High-density SSiC and optimized RBSiC matrices minimize interconnected porosity, blocking corrosive species from reaching the substrate. The coatings’ high hardness resists erosive wear from clinker dust, steel scale, and textile fibers, while the superior thermal conductivity spreads heat, avoiding localized thermal stress.

Implementation success hinges on correct surface prep, controlled coating thickness, and a firing profile matched to substrate and duty. Sicarbtech provides standard operating procedures for grit blasting, chemical cleaning, and preheat schedules, alongside thickness specifications that balance thermal shock tolerance with barrier function. In the Pakistani context, where maintenance windows can be tight, we align application sequences with planned outages and provide remote or on-site technical oversight.

On compliance, Sicarbtech delivers full material traceability, quality documentation under ISO 9001, and test reports for adhesion, porosity, and thermal cycling. While Pakistan does not mandate a single certification for SiC coatings, plants often reference international standards for ceramic components and quality systems. We support customer audits and integrate with plant safety protocols, including hot-work permits, fume extraction, and environmental guidelines to minimize particulate release during preparation and post-processing.

“Reliability is not an accident; it is designed into the microstructure and verified in the process log,” says a senior process engineer collaborating on several South Asian reliability programs. “Without porosity control and verified adhesion, coatings fail at the first shock.” (General citation: reliability engineering workshops, 2023)

Sicarbtech custom manufacturing and technology transfer services

Sicarbtech’s advantage lies not only in material science but in our turnkey delivery model. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D team refines glaze formulations, adjusts particle size distributions, and optimizes firing schedules to balance toughness, conductivity, and chemical stability for each application. Proprietary manufacturing routes allow us to produce R-SiC, SSiC, RBSiC, and SiSiC grades with repeatable batch-to-batch consistency.

For Pakistani partners considering localization, we provide complete technology transfer packages. These include process know-how, equipment lists (kiln types, atmosphere control, mixers, mills, classifiers), facility layout recommendations, utilities specifications, and detailed SOPs for surface prep, coating, firing, and inspection. Training programs cover operator skills, QC protocols, and maintenance of critical equipment. We also conduct feasibility studies, assist in vendor selection, and support commissioning, ensuring that the new line reaches quality targets from day one.

Quality assurance is embedded. Our QC system encompasses raw material certification, green-body density checks where relevant, fired density and porosity measurement, adhesion testing (pull-off/shear), and non-destructive inspection for coating continuity. We provide certification support aligned with ISO 9001 and customer-specific audit requirements common among Pakistan’s export-ready textile and steel producers.

Just as important, the relationship does not end at delivery. Our ongoing technical support includes on-site trials, failure analysis when needed, and process optimization to extend service life and improve cost per operating hour. This continuous improvement philosophy has helped us support more than 19 enterprises globally, delivering measurable ROI through longer campaigns, reduced downtime, and safer operation.

Specification-focused comparison for Pakistani plants

Title: Selecting the right SiC glaze system by duty and sector

| Application context (Pakistan) | Recommended SiC grade | Typical coating thickness | Target properties | Notes on integration |

|---|---|---|---|---|

| Cement kiln nose ring, cooler grates | SiSiC or RBSiC | 300–800 µm | High abrasion resistance, good thermal shock | Validate adhesion on high-temp alloy fixtures; manage thermal gradients |

| Steel heat-treatment fixtures | SSiC (with bonding interlayer) | 200–600 µm | Low porosity, chemical inertness, dimensional stability | Match CTE with substrate; controlled preheat and cool-down |

| Pickling line splash zones | SSiC | 250–500 µm | Acid vapor resistance, surface integrity | Emphasize sealing of edges and penetrations |

| Textile stenter burner zones | RBSiC | 200–400 µm | Smooth surface, crack resistance, heat spreading | Lower Ra finish to reduce lint adhesion |

| Waste-heat recovery exchangers | SSiC or R-SiC | 300–700 µm | Thermal conductivity, oxidation resistance | Inspect flow-facing surfaces for erosive wear patterns |

These guidelines reflect typical Pakistani operating conditions, with metric thickness ranges and integration notes that align with local maintenance practices.

Cost and lifecycle analysis tailored to Pakistan

Title: Total cost of ownership comparison for industrial coatings

| Lifecycle factor | SiC glaze coatings (Sicarbtech) | Conventional ceramic coatings | Metallic overlays |

|---|---|---|---|

| Upfront cost per m² | Medium to high | Medium | Low to medium |

| Service life in harsh zones | 1.5–3× vs metal | ~1–1.5× vs metal | Baseline |

| Unplanned downtime risk | Low | Medium | High |

| Maintenance frequency | Extended intervals | Periodic | Frequent |

| Fuel/energy impact | Positive via thermal stability | Neutral to modest | Neutral/negative under oxidation |

| Availability and lead time | Planned batches + local stocking options | Variable | Readily available but shorter life |

| ROI in Pakistan (PKR) | 8–18 months typical | 12–24 months | Baseline |

When Pakistani plants factor in PKR volatility and import timelines, longer-life solutions reduce exposure. SiC glaze systems often deliver payback within the first maintenance cycle by cutting unplanned stoppages and stabilizing process temperatures.

Future market opportunities and 2025+ trends

Looking beyond 2025, three converging trends are shaping demand for SiC glaze coatings. First, energy efficiency and decarbonization initiatives will prioritize components that maintain stable heat profiles and reduce thermal losses. SiC’s high thermal conductivity supports better heat management and faster, safer transitions, complementing digital kiln control and furnace optimization programs increasingly deployed in Pakistan.

Second, reliability-centered maintenance is becoming the norm. As more plants implement predictive analytics, components with consistent material behavior are essential to accurate life modeling. SiC’s microstructural stability under cyclic loads makes predictions more trustworthy, enabling smarter shutdown planning and inventory control.

Third, supply chain resilience and localization are strategic imperatives. With Sicarbtech’s technology transfer and potential for local finishing or partial manufacture, Pakistani partners can reduce lead times and currency exposure while building internal capability. This aligns with broader industrial policy goals and the needs of export-driven sectors to demonstrate resilient operations to international buyers.

In short, SiC glaze coatings are not a luxury; they are a pragmatic response to competitive pressures. Plants that standardize on high-performance coatings will be better positioned to manage energy, quality, and uptime targets simultaneously.

Frequently asked questions

How do SiC glaze coatings handle rapid thermal cycling common in cement and steel operations?

SiC combines high thermal conductivity with low thermal expansion, allowing heat to spread quickly and reducing internal stress. Properly applied SSiC and RBSiC glazes have demonstrated critical ΔT resistance in the 200–300 °C/min range, which suits rapid ramp-up and cool-down encountered in Pakistani plants.

Are SiC glaze coatings compatible with local maintenance practices and equipment?

Yes. Sicarbtech provides SOPs for surface prep, application, firing, and inspection that align with standard blasting and furnace equipment available in Pakistan. Where needed, we support adjustments to firing profiles or interlayer use to match existing assets.

What certifications and documentation does Sicarbtech provide?

We supply full material traceability, ISO 9001-aligned quality documentation, and test reports for adhesion, porosity, hardness, and thermal cycling. We also support customer audits and integrate with plant safety and environmental procedures.

Can SiC glaze coatings be applied to existing metal components without redesign?

In many cases, yes. We evaluate substrate alloy, geometry, and operating profile, then propose an interlayer and glaze thickness that match the component’s CTE and duty. This approach minimizes redesign while maximizing adhesion and life.

What is the typical ROI for Pakistani plants adopting SiC glaze coatings?

Most plants observe payback within 8–18 months, driven by longer service intervals, fewer unplanned stoppages, and improved thermal stability that supports energy efficiency. Detailed TCO models can be developed using your maintenance and production data.

How do SiC glazes perform in corrosive environments like pickling or SOx-rich gases?

SSiC glazes have minimal open porosity and strong chemical inertness, resisting acid vapors and sulfur-bearing gases better than many conventional ceramics or metallic overlays. Edge sealing and correct thickness further enhance durability.

Can Sicarbtech help establish local coating or component manufacturing capability?

Yes. Through our technology transfer programs, we deliver process know-how, equipment specifications, plant layouts, training, and commissioning support. This enables Pakistani partners to localize parts of the value chain under robust quality controls.

What after-sales technical support is available?

We provide remote and on-site technical assistance, trial supervision, failure analysis, and process optimization services. Our aim is to keep improving campaign life and reduce your cost per operating hour over time.

Which SiC grade should I choose for textile stenter ovens versus cement kilns?

For textiles near burner zones, RBSiC with a smooth, low-Ra glaze helps reduce lint adhesion and resists cycling. For cement kiln nose rings and coolers, SiSiC or RBSiC provides strong abrasion resistance and thermal shock tolerance.

How do you ensure consistency across coating batches?

We control powder sourcing, particle size distribution, slurry chemistry, and firing schedules in-house. Batch records, in-process QC, and final testing ensure repeatability—critical for predictive maintenance integration.

Making the right choice for your operations

Selecting an industrial coating is ultimately a risk management decision. The right SiC glaze system stabilizes heat flow, resists chemical and abrasive attack, and keeps components in tolerance longer—converting maintenance uncertainty into predictable campaigns. Begin with a mapping of high-risk zones, quantify the cost of current failures, and align coating grade and thickness to each duty. When evaluated through a total cost and reliability lens, Sicarbtech’s SiC glaze coatings typically shift from “premium buy” to “standard specification” because they lower the real cost per ton produced.

Get expert consultation and custom solutions

Whether you operate a cement kiln, a steel heat-treatment line, or a high-temperature textile oven, Sicarbtech can help engineer an SiC glaze solution that meets your performance, budget, and compliance goals. Engage our application engineering team for a structured assessment, pilot coating run, and ROI model tailored to Pakistan’s market conditions. Reach us at [email protected] or +86 133 6536 0038 to schedule a technical discussion.

Article metadata

Last updated: 11 October 2025

Next scheduled review: 11 January 2026

Content freshness: aligned with 2025 market trends, field-validated specs, and localized Pakistan case insights.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.