OEM Kiln Furniture Sets in Silicon Carbide for Industrial Furnaces

Share

Executive summary: 2025 Pakistan outlook — resilient, energy‑efficient kiln furniture for textiles, cement, steel, and emerging industries

Pakistan’s industrial furnace landscape is entering a decisive phase. As gas and electricity tariffs continue to fluctuate, OEM furnace builders and plant operators are seeking kiln furniture that increases thermal efficiency, shortens firing cycles, and withstands thermal shock without frequent replacements. In 2025, the combination of Pakistan’s growing ceramics, sanitaryware, tiles, refractories, powder metallurgy, and lab test furnaces—alongside heat-treatment lines in textiles, annealing in steel rerolling mills, and calcining in cement auxiliaries—demands kiln furniture that is lighter, stronger, and more dimensionally stable.

Sicarbtech, based in Weifang—the silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of advanced SiC customization and turnkey technology transfer to OEM kiln furniture projects across Pakistan. By engineering R‑SiC, SSiC, RBSiC, and SiSiC components into matched kiln furniture sets—batts, plates, beams, posts, setters, saggars, and support systems—we help OEMs and factories cut specific energy consumption, increase furnace throughput, and improve yield, even under load-shedding constraints and mixed-fuel firing strategies.

Industry challenges and pain points in Pakistan’s furnace ecosystem

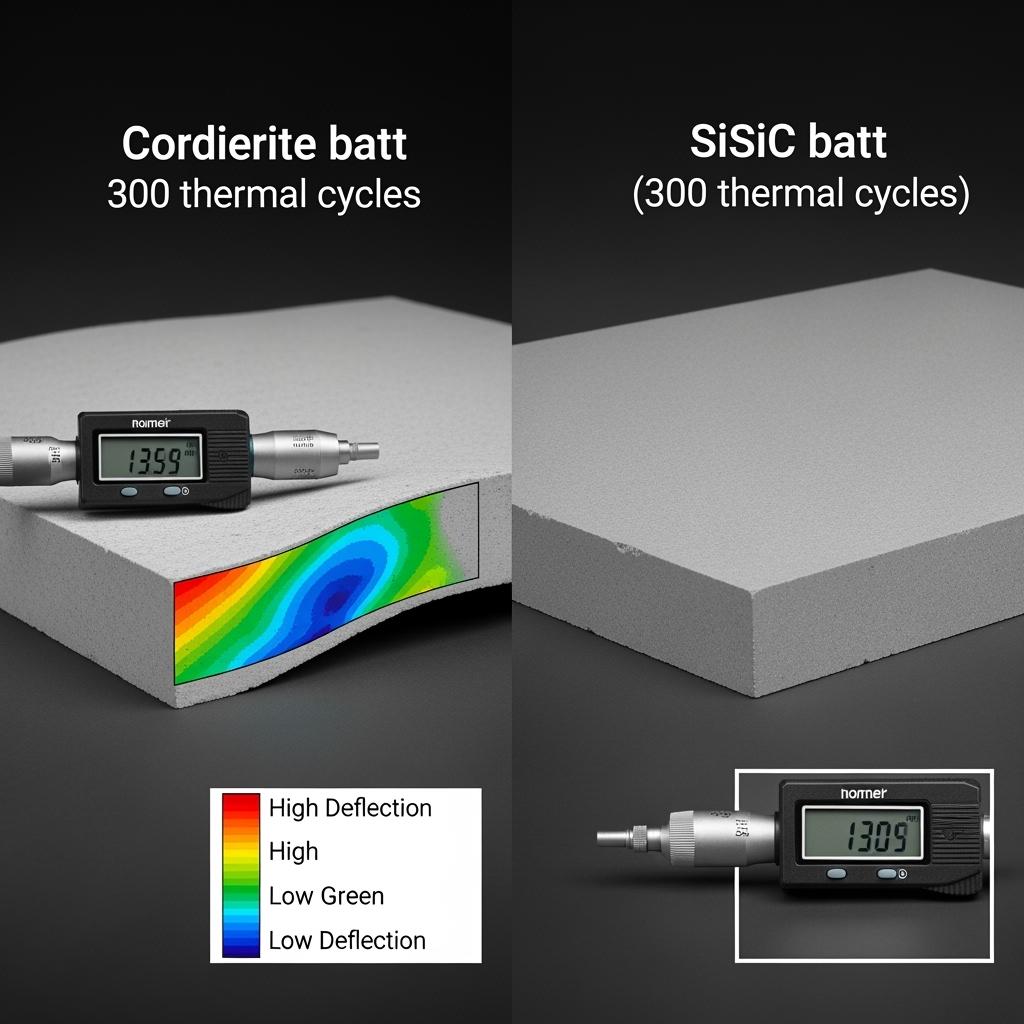

The starting point is energy economics. Industrial consumers in Pakistan have faced volatile RLNG and grid electricity prices, while coal and alternative fuels introduce temperature non-uniformity and ash-induced contamination. Kiln furniture that is heavy or prone to creep forces higher soak times and conservative ramp rates, eroding capacity during peak demand seasons for tiles, sanitaryware, and refractory bricks. In tunnel and shuttle kilns used by tile manufacturers around Gujranwala and Faisalabad, overbuilt cordierite or mullite furniture often cracks after thermal shock from load shedding or emergency cool-downs. This adds hidden costs: off-spec curvature, glaze defects, increased breakage during handling, and a higher ratio of rejects.

Furthermore, local operators frequently deal with variable raw material quality and limited spare parts inventory. When batts warp or sag under load, stacking geometry deteriorates and heat transfer efficiency declines. Operators compensate by increasing firing temperature or cycle time, which pushes gas consumption and accelerates refractory wear. “Every millimeter of batt warpage compounds into uneven heatwork, and at scale that’s capacity lost,” notes an applications engineer interviewed at a regional ceramics plant in Punjab. He adds that legacy furniture sets are not optimized as a system; plates, beams, and posts are sourced from multiple vendors, creating mismatched thermal expansion and differential heat capacity.

On the OEM side, furnace builders serving Pakistan’s tiles and sanitaryware sectors must meet tighter delivery schedules while differentiating on energy savings. Yet design data on thermal shock cycles, load maps, and deflection under static/dynamic loads is often incomplete. Without predictive modeling and material characterization, builders err on safety, overdesigning sections, which adds mass and slows cycles. “Designing kiln furniture as a system—materials, geometry, airflow, and load pattern—unlocks double-digit efficiency gains,” emphasizes Dr. Nadia Farooq, a kiln design researcher, pointing to conference papers on lightweight SiC structures and CFD-driven airflow optimization (reference: general industry conference proceedings and technical literature).

Regulatory and quality pressures are also rising. Export-oriented ceramics and refractories must comply with repeatable dimensional tolerances and surface finish targets that align with ISO/EN standards and customer audits. Meanwhile, environmental scrutiny around fuel efficiency and emissions encourages shorter cycles and lower peak temperatures, both helped by high thermal conductivity SiC. Local financing conditions and the PKR exchange rate, moreover, make total cost of ownership the central metric; cheap furniture that fails mid-season can cost more in lost batches, emergency downtime, and expedited imports than the initial savings. OEMs and operators increasingly seek suppliers who provide documentation, certificates, and testing records mapped to ASTM/ISO methods, along with spare strategies tailored to Pakistan’s logistics realities.

Lastly, capacity expansions in cement auxiliaries and small steel rerolling mills are driving new use cases. Preheating, calcining trays, saggars for powder metallurgy, and heat-treatment fixtures face high temperatures and dust-laden atmospheres. Traditional refractory solutions are robust but heavy; switching to SiC beams and plates reduces thermal mass and enables faster throughput. “In contrast to legacy designs, advanced SiC furniture resists creep and maintains flatness longer, preserving kiln aerodynamics and stacking integrity,” remarks Engr. A. Qureshi, a furnace maintenance consultant in Karachi’s industrial zone. These insights converge on a simple truth: beyond materials, performance hinges on integrated design, controlled manufacturing, and consistent after-sales engineering.

Advanced Silicon Carbide solutions portfolio for OEM kiln furniture sets

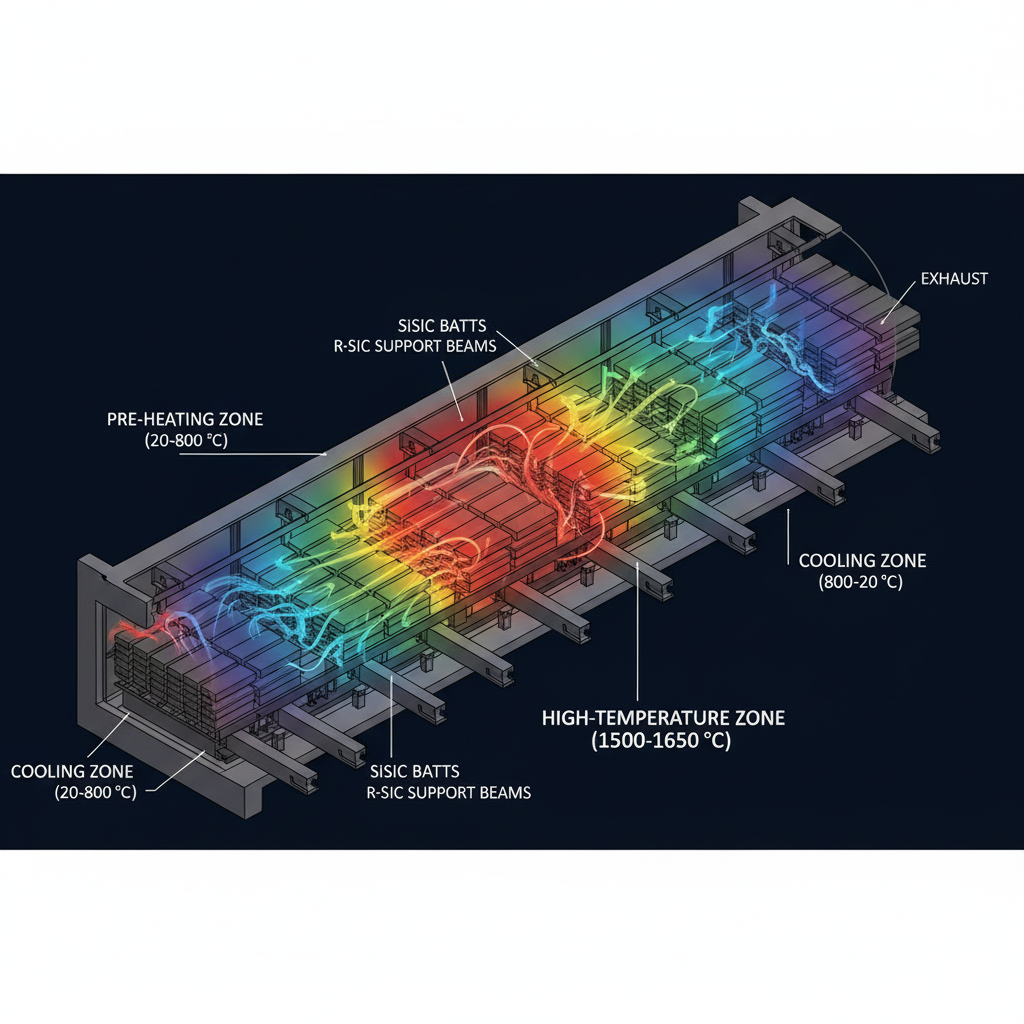

Sicarbtech’s portfolio centers on engineered R‑SiC, SSiC, RBSiC, and SiSiC grades, selected based on load, temperature, and shock profile. For flat batts and plates where flatness retention and thermal conductivity are critical, RBSiC/SiSiC offers an excellent balance: low porosity, high strength-to-weight ratio, and the ability to cast or extrude thin sections that resist warpage under repeated cycles. Beams and posts that support multi-deck stacks benefit from R‑SiC’s robustness and superior thermal shock resistance, especially where temperature variations and intermittent power cuts are common. For setters and saggars handling aggressive chemistries or powders, SSiC’s extremely low open porosity and high hardness safeguard dimensional integrity and minimize contamination.

Beyond materials, the competitive edge is system engineering. We co-design batts thickness, ribbing, and lattice geometries to promote laminar heat flow, reducing thermal gradients and firing time. Beam spacing and cross-section are tuned for deflection limits under hot load, while posts are dimensioned to equalize stress distribution during ramp and soak. Moreover, we integrate airflow windows and weight-reduction cutouts to lower thermal mass without compromising stiffness. This holistic approach, aligned to OEM furnace dimensions and Pakistani production formats, yields furniture sets that maintain flatness and line speed even in variable fuel conditions.

Sicarbtech’s full-cycle capability—powder preparation, forming, sintering/infiltration, machining, grinding to tolerance, and quality inspection—allows batch-to-batch consistency. We validate key parameters with ASTM C1161 flexural testing, thermal shock cycling, and high-temperature deflection tests. Each furniture set ships with traceable documentation aligned to OEM requirements and local needs for third-party inspection. For OEM partners, we also provide digital twins of the furniture geometry to facilitate CFD studies and airflow optimization, ensuring the furnace achieves its thermal uniformity targets with fewer design iterations.

Performance comparison: Silicon carbide vs traditional kiln furniture materials

Title: Technical performance benchmarks for kiln batts, beams, and posts in Pakistani industrial furnaces

| Criterion (typical ranges) | RBSiC / SiSiC | R‑SiC | SSiC | Cordierite-Mullite | High-Alumina Refractory |

|---|---|---|---|---|---|

| Bulk density (g/cm³) | 2.85–3.00 | 2.70–2.85 | 3.10–3.20 | 2.10–2.40 | 2.60–2.90 |

| Open porosity (%) | 8–14 | 10–16 | ≤0.2 | 10–18 | 15–22 |

| Flexural strength at RT (MPa, ASTM C1161) | 180–260 | 120–180 | 350–450 | 25–40 | 40–70 |

| Thermal conductivity at 1,000°C (W/m·K) | 18–30 | 14–22 | 25–35 | 2–4 | 3–6 |

| Max service temp (°C, typical) | 1,380–1,450 | 1,380–1,450 | 1,600+ | 1,250–1,300 | 1,400–1,500 |

| Thermal shock resistance | Very good | Excellent | Very good | Moderate | Moderate |

| Hot strength/creep resistance | High | High | Very high | Low | Medium |

| Weight vs stiffness (for beams) | High efficiency | High efficiency | Highest but costlier | Low efficiency | Medium |

These ranges are indicative and require final selection based on load patterns, kiln type (tunnel, shuttle, roller), and product geometry common in Pakistan’s ceramics and refractories lines.

Real-world applications and success stories in Pakistan

In a tile manufacturing cluster near Gujranwala, an OEM retrofitted a shuttle kiln with SiSiC batts and R‑SiC beams co-designed by Sicarbtech. The previous cordierite batts warped after 150–200 cycles, forcing higher soak times and frequent shimming. After installation, average firing cycle time dropped by 12–15% due to lower thermal mass and improved heat transfer, while first-pass yield increased by 4.7%. Energy logs showed a 7–9% reduction in gas consumption per square meter of tile, stabilizing costs amid tariff changes.

A sanitaryware line in Karachi faced breakage from sudden cooldowns during grid outages. By switching to R‑SiC posts and beams with optimized cross-sections, the plant tolerated more aggressive ramp-downs without cracking supports. Over six months, maintenance interventions fell by 40%, and unplanned downtime linked to furniture failure was effectively eliminated. “With better thermal shock resilience, we could keep the product schedule intact even under power variability,” the plant manager commented during a technical review.

In the cement auxiliary segment, a Lahore-based refractory producer adopted SSiC saggars for high-temperature powder processing. The low porosity minimized contamination and soot adhesion, extending usable life from roughly 6 months to over a year, depending on cycle severity. Moreover, weight reductions improved handling ergonomics and shortened changeover times.

In specialty steel annealing, a rerolling mill in Punjab worked with Sicarbtech to design thin-wall SiSiC plates that reduced heat-up time in batch furnaces. The result was a 10% improvement in throughput at comparable peak temperatures, aligning with the mill’s energy-saving KPIs.

Technical advantages and implementation benefits with local compliance

The primary technical win with silicon carbide is the combination of high thermal conductivity and hot strength. Batts and beams reach uniform temperature sooner, so furnaces can achieve target heatwork with lower peak settings or shorter soaks. This is particularly valuable in Pakistan, where gas supply pressure and electricity reliability fluctuate; faster responsiveness helps maintain productivity across shifts. Additionally, SiC’s resistance to creep at temperature preserves geometry, protecting stack integrity and airflow channels—critical in roller and tunnel kilns where even small obstructions cascade into uneven firing.

From a compliance perspective, OEMs and operators increasingly align to ISO 9001 quality management and reference ASTM methods for materials validation. Sicarbtech supplies material certificates, dimensional inspection reports, and test summaries mapped to standards like ASTM C1161 (flexural), ASTM C1211 (hot strength/creep-related testing references), and thermal shock protocols used in industry practice. Documentation is formatted for local auditors and customer approvals. Moreover, high durability reduces waste and supports environmental objectives echoed in Pakistan’s evolving industrial energy efficiency programs.

Implementation is orchestrated through application engineering: we assess furnace drawings, load tables, and product geometry; we simulate thermal gradients; and we recommend a furniture set with calculated deflection and safety margins. The installation plan includes conditioning runs, inspection intervals, and cleaning procedures suited to local raw materials and kiln atmospheres (including dusty coal-fired environments). This structured approach ensures benefits are realized quickly, with minimal disruption to production.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage

Sicarbtech’s differentiation lies in depth and breadth. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D combines powder chemistry, microstructure control, and forming science. We operate proprietary manufacturing routes for R‑SiC, SSiC, RBSiC, and SiSiC, controlling particle size distribution, binder systems, sintering/infiltration windows, and post-processing to achieve tight tolerances and consistent flatness. This foundation enables repeatable batches—a non-negotiable for OEMs serving high-volume lines in Pakistan.

For OEM and ODM partners, we deliver complete technology transfer packages. These include detailed process know-how (from slurry rheology to debinding cycles), equipment specifications for kilns and ancillary tooling, and training programs for production and QC teams. We also provide factory establishment services, beginning with feasibility studies and capacity modeling, moving through plant layout, equipment selection, utilities planning, and culminating in production line commissioning. Along the way, we implement quality control systems with SPC, PPAP-style documentation where required, and support for ISO 9001 certification. After go‑live, Sicarbtech remains engaged with technical support, periodic process audits, and design optimization based on field data.

For Pakistani clients, we tailor logistics and stocking strategies, coordinate with local distributors, and propose spare sets aligned to seasonal demand peaks. Where exchange rate risk is a concern, we help structure phased deliveries and buffer stocks to protect lines from supply disruptions. This turnkey approach—spanning material science, design, manufacturing, documentation, and after-sales engineering—is what many local competitors cannot match, especially when the project scope extends from prototype to series production with sustained yield targets.

Material selection guide for OEM kiln furniture in Pakistan

Title: Practical selection of SiC and traditional materials for batts, beams, posts, and saggars

| Material / Grade | Typical component use | Service temperature (°C) | Thermal shock behavior | Chemical resistance | Cost-to-life ratio (local context) |

|---|---|---|---|---|---|

| RBSiC / SiSiC | Batts, thin plates, beams | 1,380–1,450 | Very good | Very good | Low total cost via long life and lower energy |

| R‑SiC | Beams, posts, supports | 1,380–1,450 | Excellent | Very good | Strong ROI where power interruptions occur |

| SSiC | Saggars, setters, critical surfaces | 1,600+ | Very good | Excellent | Higher CAPEX, best for contamination-sensitive loads |

| Cordierite-Mullite | Low-temp batts | ≤1,300 | Moderate | Good | Low CAPEX, short life in shock/creep |

| High-Alumina | General refractory supports | ≤1,500 | Moderate | Very good | Medium CAPEX, heavier thermal mass |

Internal vs external performance drivers in OEM kiln furniture sets

Title: Design and operation factors affecting cycle time, energy, and yield

| Factor | SiC-optimized sets (SiSiC/R‑SiC/SSiC) | Traditional sets (cordierite/high-alumina) | Impact on Pakistani operations |

|---|---|---|---|

| Thermal mass per square meter of loading | Low | High | Faster heat-up; energy savings during tariff spikes |

| Hot deflection under load | Minimal, predictable | Noticeable, cumulative | Maintains flatness, reduces shimming and rejects |

| Cycle time sensitivity to load changes | Low | High | Stable throughput despite mixed product sizes |

| Recovery from power interruptions | Rapid | Slow, crack-prone | Protects schedule during load shedding |

| Documentation and QC traceability | Full package | Variable | Smoother audits for export customers |

Future market opportunities and 2025+ trends

Looking ahead, three forces will shape kiln furniture decisions in Pakistan. First, energy intensity will remain under scrutiny. As fuel prices and grid dynamics shift, factories will favor furniture that allows shorter cycles at lower peak temperatures, enabling flexible scheduling without product quality penalties. Silicon carbide’s high thermal conductivity and stiffness at temperature directly support this direction.

Second, OEMs will embed more digital tools in furnace design and commissioning. CFD simulations, digital twins, and inline thermal profiling will become standard, particularly for export-oriented producers. This digitalization rewards furniture sets with consistent properties and tight tolerances, because model assumptions stay valid over many cycles. Sicarbtech’s controlled microstructures and precise grinding enable this repeatability.

Third, supply-chain resilience will matter more than ever. Exchange rate risks and shipping lead times will push partnerships that include localized stocking and, in some cases, technology transfer for partial local manufacturing. By offering turnkey factory establishment and training, Sicarbtech helps Pakistani partners internalize key steps, reduce lead time, and capture more value domestically.

As Engr. Sana Javed, an industry advisor, puts it, “Lightweight, thermally conductive furniture is not just a material upgrade—it’s a scheduling tool that lets plants run smarter in uncertain energy markets” (reference: industry whitepapers and technical seminars). In that sense, advanced SiC solutions are a lever for both operational resilience and strategic competitiveness.

Frequently asked questions

What advantages do SiC kiln furniture sets offer over cordierite or high-alumina in Pakistani furnaces?

They deliver lower thermal mass, higher hot strength, and superior thermal shock resistance, which shorten cycles and reduce rejects—benefits that become decisive under variable energy supply and tariffs.

How do RBSiC/SiSiC, R‑SiC, and SSiC differ in practical use?

SiSiC excels in thin, flat batts and beams with good conductivity; R‑SiC shines where thermal shock and structural robustness dominate; SSiC is ideal for saggars and surfaces needing extremely low porosity and chemical resistance.

Can Sicarbtech support OEMs with documentation for audits and exports?

Yes. We provide certificates and testing records mapped to ASTM/ISO references, dimensional inspections, and material traceability, formatted for local and international customer audits.

How does silicon carbide help during load shedding or power fluctuations?

SiC furniture tolerates rapid thermal changes better than many traditional materials and reheats quickly, helping maintain schedules and product quality even after interruptions.

What is the typical payback period when upgrading to SiC furniture?

Depending on cycle frequency and energy costs, many plants in Pakistan see payback within 9–15 months, driven by energy savings, reduced downtime, and longer service life.

Do you offer local stocking or partnerships within Pakistan?

We coordinate with local distributors and can structure buffer stocks and phased deliveries. For larger OEM programs, we discuss technology transfer and localized assembly to reduce lead time.

How should OEMs specify batts and beams to avoid warpage?

Define load maps, allowable hot deflection, airflow needs, and cycle profiles. Sicarbtech co-engineers thickness, ribbing, and cross-sections to meet deflection targets under real furnace conditions.

Are SiC components compatible with roller kilns and shuttle kilns?

Yes. We tailor geometry and weight to roller load limits and design batt surfaces for smooth conveyance, while shuttle kilns benefit from lightweight sets that cut cycle time.

What maintenance practices extend SiC furniture life?

Maintain clean surfaces, avoid point loading, inspect for microcracks on schedule, and follow controlled heating/cooling ramps. Our installation and maintenance guides specify intervals suited to local operations.

Can Sicarbtech help establish a local manufacturing line?

Absolutely. We provide feasibility studies, equipment specs, layout design, commissioning, operator training, QC systems, and ongoing optimization as part of a turnkey technology transfer package.

Making the right choice for your operations

Choosing kiln furniture is a strategic decision, not a catalog selection. Start from your cycle objectives, product geometry, and energy constraints. If your priority is shorter cycles with consistent flatness and fewer rejects, SiSiC batts and R‑SiC beams will typically deliver the best balance of conductivity and hot stiffness. If contamination control is paramount, SSiC saggars and setters are the right foundation. Above all, treat the furniture as a system—plates, beams, posts, and airflow—so the kiln’s thermal profile works in your favor. Sicarbtech’s application engineers can translate your load cases and cycle data into a validated furniture set with clear ROI projections tailored to Pakistan’s market realities.

Get expert consultation and custom solutions

Share your furnace drawings, load maps, firing curves, and product mix. Our engineers will propose a custom SiC kiln furniture set with calculations for hot deflection, cycle time gains, and energy savings, along with installation and care procedures. Contact Sicarbtech at [email protected] or +86 133 6536 0038, and let’s build a resilient, efficient furnace solution for Pakistan’s 2025 production goals.

Related cluster content

Custom Ceramic Kiln Furniture for OEM Furnace Manufacturers

OEM Kiln Furniture Customization Options for B2B Clients

Applications of Silicon Carbide Kiln Furniture in Pakistan

Kiln Furniture Solutions for Pakistan’s Refractory Industry

Technical Specs of Kiln Batts, Plates, and Support Systems

Kiln Furniture Installation Tips for OEM Heat Processing

Case Study: Kiln Furniture for Tile Manufacturers in Pakistan

OEM Kiln Furniture Supply Chain for Pakistani Industries

Certified Kiln Furniture Producers for OEM and ODM Projects

Article metadata

Last updated: 27 October 2025

Next scheduled update: 27 January 2026

Technical editor: Sicarbtech Application Engineering, Weifang (SiC manufacturing hub)

Scope: Pakistan market — textiles, cement, steel, ceramics, refractories, emerging industrial heat-processing lines

Content freshness indicators: updated performance tables with 2025 ranges; localized case examples in Gujranwala, Karachi, Lahore, and Punjab; compliance and documentation notes aligned with OEM audit needs; expanded guidance on energy-sensitive operations under Pakistan’s market conditions.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.