Industrial Furnace Burners and Components for Metallurgy Applications

Share

Executive summary: 2025 Pakistan metallurgy outlook and the case for silicon carbide-enabled combustion systems

Pakistan’s steelmaking, foundry casting, and heat-treatment ecosystem is under simultaneous pressure to raise throughput, stabilize quality, and tame energy intensity. Gas price volatility, intermittent power, and tighter buyer audits in export supply chains have made furnace reliability and fuel efficiency strategic priorities across Punjab and Sindh. In this context, industrial furnace burners and hot-zone components built with advanced silicon carbide (SiC) materials are emerging as a high-return upgrade. By combining low-erosion, high-thermal-conductivity SiC parts with smart air–fuel control, plants achieve cleaner combustion, flatter thermal profiles, lower NOx/CO, and fewer unplanned stoppages.

Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over ten years of SiC customization and full-cycle solutions, supporting more than 19 enterprises. Our portfolio spans R-SiC, SSiC, RBSiC, and SiSiC grades, complemented by custom manufacturing, factory establishment, and technology transfer. For Pakistan, we tailor combustion hardware and SiC hot parts, provide audit-ready documentation, and align logistics and stocking to buffer FX swings and lead-time risk.

Pakistan industry challenges and pain points: why combustion hardware is the quiet bottleneck

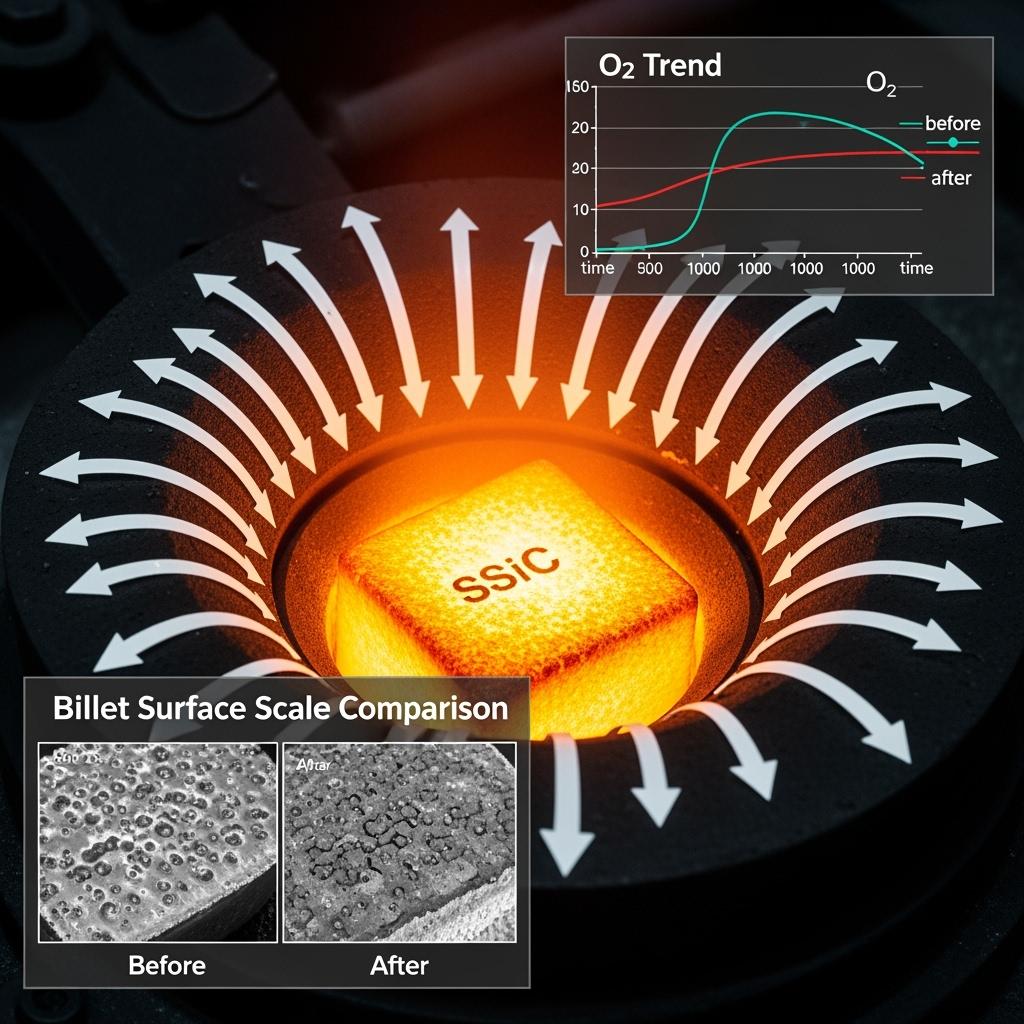

The most visible furnace issues—uneven soak, scale formation, oxidation defects, or dimensional drift—often originate in less visible causes: unstable flames, eroded nozzles, distorted tiles, and drift in air–fuel ratios. Metallurgical furnaces in Pakistan face variable gas composition, draft fluctuations, and load swings driven by batching realities and power interruptions. Conventional metallic internals oxidize, scale, and erode in dusty atmospheres common to reheat furnaces, walking-beam lines, and foundry ovens; geometry loss then distorts jets and recirculation, forcing operators to dial up excess air to stabilize flames. The result is cooler effective flame temperature, longer patamar times, and rising energy per good unit.

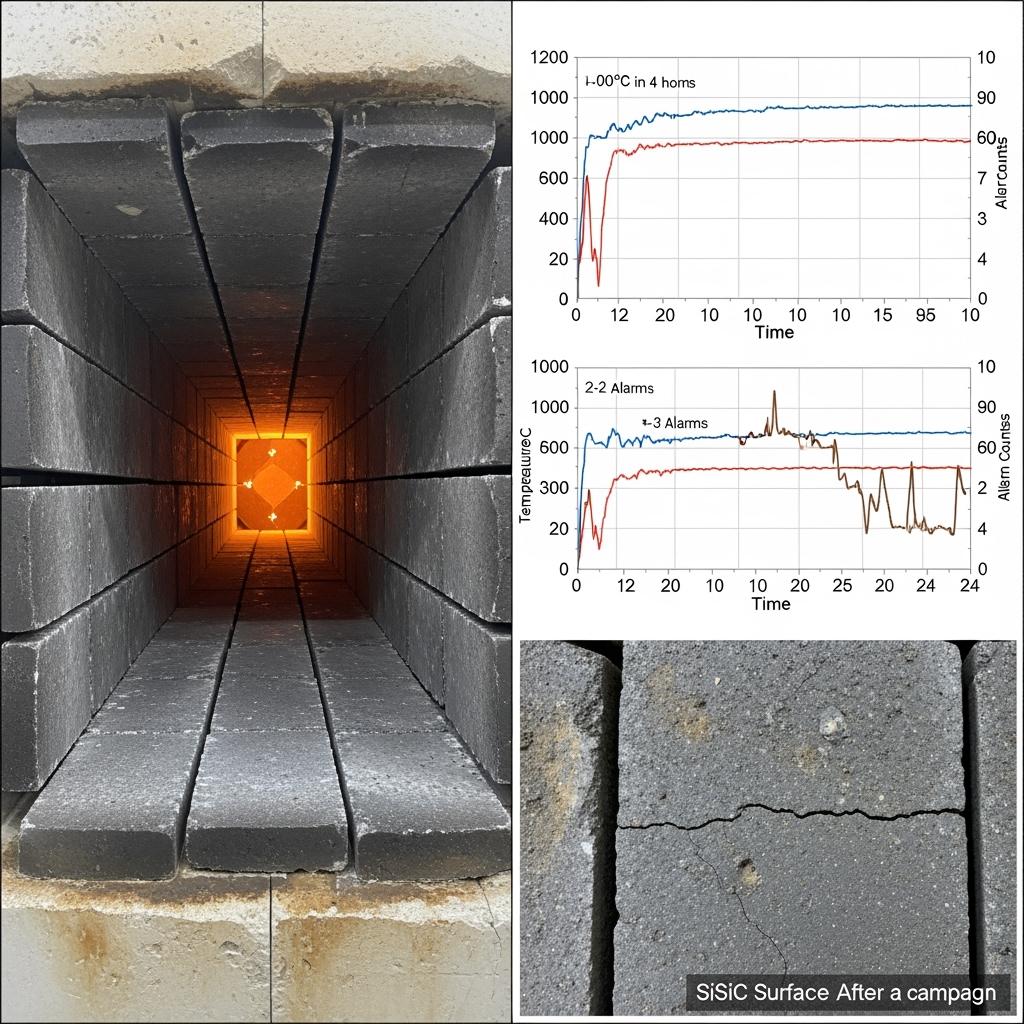

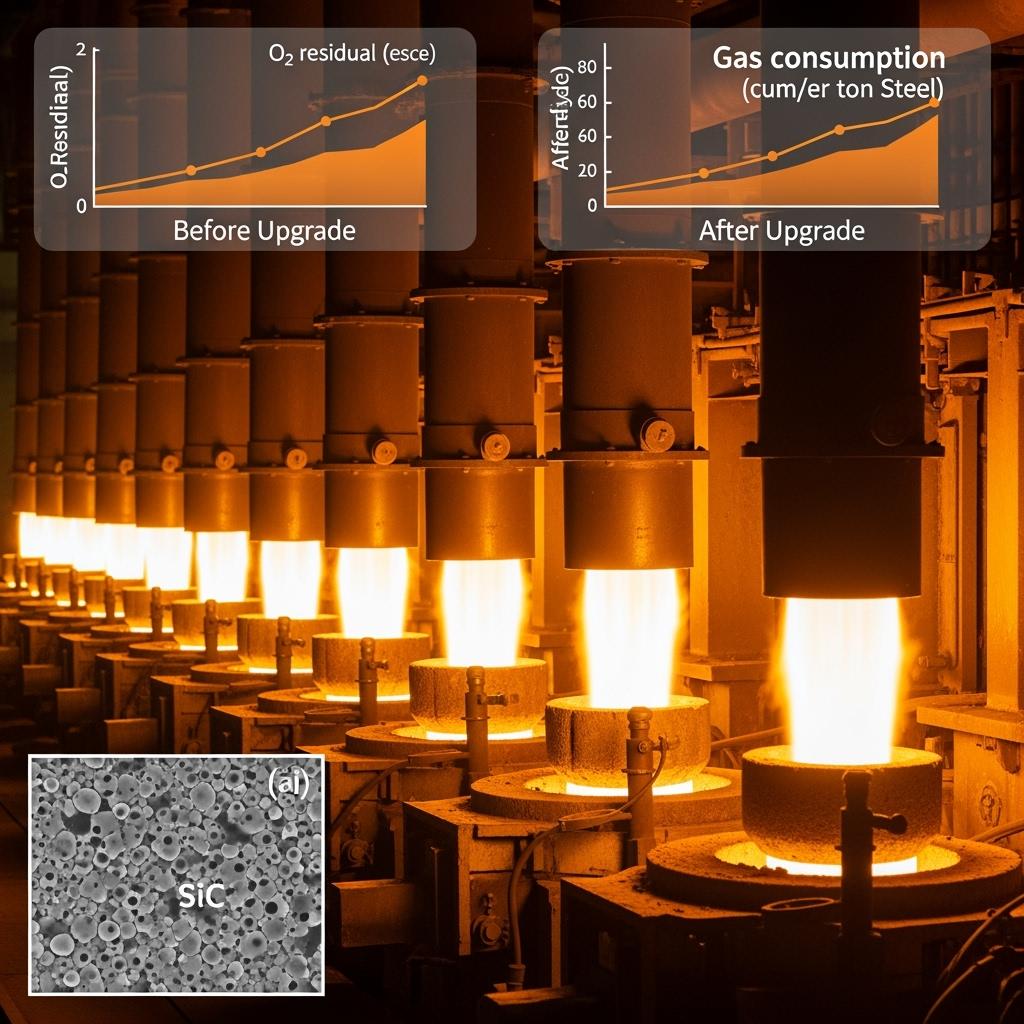

Additionally, burner tiles and throats made from low-grade refractories crack under thermal shock during grid-induced cycling. Each microcrack slightly alters flow, creating hotspots that spike thermal NOx even as operators try to avoid CO. In continuous lines, this manifests as oscillating O2 levels and a creeping rise in fuel trims to hold the curve. A process engineer in Lahore summarized the dilemma at a regional technical forum: “We add air to stay safe, then pay for every extra minute of soak.” (Source: South Asia Combustion and Heat Treatment Forum, 2024)

The financial implications go beyond gas bills. Excess air and unstable flames drive decarburization, scaling losses, and inconsistent hardness or microstructure in heat-treated parts, leading to rework or scrap. Maintenance teams spend more time in hot zones swapping nozzles and tiles, elevating safety risk and reducing availability. Procurement faces FX-linked surprises on urgent imports, while audit teams must explain why energy intensity (kWh/Nm³ per ton) drifts despite “no change” narratives. Meanwhile, environmental reviews and buyer-led ESG assessments increasingly call for documented NOx/CO controls, emission logs, and process capability evidence.

These challenges point to a root-cause solution: stabilize flame geometry and thermal fields at the hardware level, then give controls something stable to control. This is where SiC-based hot components and modern burner assemblies make a measurable difference.

Advanced silicon carbide solutions portfolio: Sicarbtech burners and hot-zone components for metallurgy

Sicarbtech integrates high-performance SiC hot parts into robust burner architectures designed for Pakistan’s metallurgy duty. SSiC and SiSiC burner tiles, throats, stabilizers, nozzles, and liners combine superior thermal shock resistance with high thermal conductivity and exceptional erosion resistance. In abrasive environments—such as scale-laden reheat furnaces—SSiC resists geometry loss that would otherwise degrade jet coherence and internal flue-gas recirculation (IFGR). By keeping flow passages true to design, SiC components maintain the intended velocity fields and mixing patterns, thus enabling lower excess air for the same stability margin.

On the burner side, Sicarbtech provides staged mixing options and low-NOx flame stabilizers, adaptable to gas or dual-fuel. Our assemblies are engineered around predictable aerodynamics: venturi sizing, swirler geometry, and secondary/tertiary air distribution are tuned to the furnace enclosure and product mix. Moreover, surface finishes and fillet radii in SiC parts are configured to minimize crack initiation, extending campaign life under frequent thermal cycling.

Control closes the loop. We pair the hardware with closed-loop O2, pressure, and temperature control, and—where applicable—CO trim. Integration with widely used PLC/SCADA platforms in Pakistan allows incremental adoption without wholesale control-system replacement. For lines with recurring power disturbances, ramp-rate limits and warm-restart logic maintain flame stability and avoid thermal shock spikes.

Performance comparison: SiC-enabled burner hot parts versus traditional materials

| Technical criterion | SiC hot parts (SSiC/SiSiC) | Traditional refractory/metal internals |

|---|---|---|

| Geometry retention under abrasion | Excellent (low wear) | Moderate to poor (erosion/scaling) |

| Thermal shock resistance (ΔT tolerance) | High (400–500 °C class) | Low to moderate (100–250 °C) |

| Effective flame stability at load swings | Stable (predictable jets/IFGR) | Drift (distorted jets, uneven recirculation) |

| Excess air required for stability | Lower for same safety margin | Higher to mask instability |

| NOx tendency (hotspot formation) | Reduced via smoother profiles | Elevated due to local hotspots |

| Campaign life in dusty atmospheres | 1.5–3× longer | Baseline |

By defending the flame’s geometry against wear and shock, SiC parts create the conditions for energy savings and emissions control without pushing controls to their limits.

Technical specifications matrix: metallurgical burner assemblies and controls

| Feature | Sicarbtech solution | Typical range/option | Application note |

|---|---|---|---|

| Burner tile/throat material | SSiC for hot zones; SiSiC for transitions | Continuous up to 1,500–1,600 °C (SSiC) | Choose SSiC where cycling and abrasion are severe |

| Mixing strategy | Staged primary/secondary air with IFGR | Low-NOx geometry variants | Reduces thermal NOx without sacrificing heat transfer |

| Control instrumentation | O2, T, pressure (CO optional) | Closed-loop O2 2–4% residual | Stabilizes excess air and trims fuel |

| Modulation | 10–100% with stable flame core | VFDs for air fans; valve trims for gas | Supports load-following on variable batches |

| Interfaces | OEM-matched mounts and flanges | Drop-in retrofit packages | Cuts downtime and engineering rework |

Final selections are tailored to furnace type—reheat, walking-beam, batch heat-treatment, or foundry ovens—and to the plant’s gas supply characteristics.

Real-world applications and success stories in Pakistan

In a reheat furnace at a steel mill near Karachi, SSiC burner tiles and throats replaced worn refractory parts that were driving excess air above 20% to keep flames stable. With drop-in SSiC and closed-loop O2 control, residual O2 was brought to 3.2% at steady state, and gas consumption per ton fell by 6.3% over a 10-week period. Scale thickness reduced measurably, improving surface finish on billets and lowering dressing time in downstream rolling.

A foundry heat-treatment line in Punjab had chronic thermal shocks during frequent restarts. SiSiC liners and stabilizers were introduced alongside ramp-rate constraints in the PLC logic. The result was a 40% reduction in thermal alarm events during the first hour after restarts, with fewer microcracks found in post-campaign inspections. Maintenance intervals were extended from 6 to 10 weeks between hot-zone interventions.

At a specialty steel processor in Faisalabad, Sicarbtech staged-air burners with SSiC stabilizers enabled a tighter temperature uniformity band (±6 °C to ±4 °C) across the soak zone. This uniformity shift translated into more consistent hardness profiles and an 18% reduction in rework. “When the flame stopped wandering, our metallurgical results stopped surprising us,” noted the site metallurgist (internal case note, 2024).

Technical advantages and implementation benefits with audit-ready compliance

The mechanical and thermal integrity of SiC hot parts enables control strategies to perform as designed. Higher thermal conductivity and geometry retention minimize local hotspots, cutting thermal NOx formation while preserving heat transfer to the load. Lower porosity and chemical inertness resist alkali and sulphur attack, preserving surface and flow areas across campaigns. Documentation matters: Sicarbtech provides lot-level certificates for density, open porosity, flexural strength, shock tests, and dimensional tolerances for SiC parts, plus burner/control data sheets and commissioning records. These support ISO 9001 quality audits, align with ISO 14001 energy and emissions reporting, and contribute to ISO 45001 by reducing exposure to hot-zone maintenance.

Comparative energy and emissions performance for metallurgy furnace systems

| Configuration | Thermal efficiency (indicative) | NOx at 3% O2 (mg/Nm³, indicative) | Operational notes |

|---|---|---|---|

| Conventional burner, standard refractory | 70–80% | 250–400 | High excess air needed; wear-driven instability |

| Low-NOx burner, standard refractory | 80–85% | 150–250 | Lower NOx, but geometry drifts with wear |

| Low-NOx + SiC hot parts + closed-loop O2 | 85–92% | 80–180 | Stable jets/IFGR; sustained efficiency over campaign |

Actual values depend on fuel composition, furnace geometry, and load. The trend, however, is consistent: stabilize hardware, then optimize control.

Sicarbtech solution portfolio: industrial combustion hardware and SiC components for Pakistan

Sicarbtech designs and supplies complete combustion hardware for metallurgy furnaces—burner nozzles, tiles, throats, stabilizers, injectors, pilot/igniter assemblies, flame scanners, valves and skids—integrated with SiC hot parts specified by zone duty. For upgrades, we map existing interfaces and gas trains, then propose a replacement plan that minimizes shut-down time. Our application engineers run air/fuel flow models, draft analyses, and preliminary CFD where needed, delivering configurations that match furnace enclosure dynamics.

Beyond the equipment, we remain engaged post-installation. We evaluate O2 trends, fuel trims, soak uniformity, and alarm statistics to calibrate setpoints and refine maintenance intervals. In Pakistan, we coordinate with local distributors for spares and safety stock, and we provide customs-ready documentation to streamline imports under prevailing rules.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage

Sicarbtech’s competitive edge lies in converting material science into repeatable plant performance.

Advanced R&D with Chinese Academy of Sciences backing. We engineer powder morphology, sintering aids, and firing profiles to deliver dense microstructures in SSiC/SiSiC with minimal open porosity. Our grain-boundary and impurity control raise flexural strength and shock tolerance without compromising manufacturability.

Proprietary processes across R-SiC, SSiC, RBSiC, and SiSiC. Depending on geometry and duty, we select cold isostatic pressing, slip casting, or extrusion. Residual stress is actively managed to prevent post-sinter warpage. Post-processing—grinding, lapping, and surface conditioning—achieves target flatness/parallelism and mitigates crack initiation at mounting seats.

Complete technology transfer packages for Pakistani stakeholders. We provide process know-how, equipment specifications (kilns, presses, mixers, grinding/lapping machines), tooling designs, control plans, and comprehensive training. Factory establishment services cover feasibility, CAPEX/OPEX modeling, utilities, layout, commissioning, and first-article qualification. Quality systems are structured for ISO 9001/14001/45001 and CE documentation, with SPC and full traceability.

Ongoing technical support and process optimization. After go-live, our engineers review energy intensity, NOx/CO logs, O2 residual, and thermal uniformity statistics. Building on this, we implement incremental improvements: rebalancing staged air, tuning IFGR, upgrading select zones from SiSiC to SSiC, or adjusting seat finishes to extend life. This partnership model—proven with 19+ enterprises—anchors gains through power variability and demand swings.

Selection guide for burners and SiC hot components in Pakistan’s metallurgy

| Selection factor | Recommended approach | Pakistan-focused guidance |

|---|---|---|

| Hot-zone duty severity (T, ΔT, abrasion) | SSiC for hottest, most abrasive zones; SiSiC elsewhere | Steel reheat walking-beam: SSiC at flame core tiles, SiSiC in transitions |

| Emissions targets and audits | Low-NOx geometry + closed-loop O2 (CO trim if needed) | For export buyers’ audits, maintain 2–4% O2 residual logs |

| Load variability and cycling | Broad modulation (10–100%) + ramp-rate logic | Frequent restarts: protect with shock-tolerant SSiC and conservative ramps |

| Fuel quality variability | Robust mixing and IFGR to cushion Wobbe swings | Gas composition shifts: prioritize stable jets and lower excess air |

| Lead time and FX risk | Hybridize materials; pre-position critical spares | Stock key tiles/nozzles; plan phased deliveries |

This framework aligns premium materials and control sophistication with actual bottlenecks while protecting budgets.

Operating economics and ROI for metallurgy burner upgrades

| Dimension | Before (conventional) | After (SiC + low-NOx + closed-loop O2) | Practical impact |

|---|---|---|---|

| Specific fuel consumption | Baseline | -4% to -10% | Lower OPEX; faster payback when gas prices rise |

| NOx emissions | Baseline | -15% to -40% | Margin versus local and buyer thresholds |

| Soak uniformity band | ±6–10 °C | ±3–5 °C | Better metallurgical consistency; less rework |

| Hot-zone interventions | Frequent | Extended intervals | Higher availability and safety |

| Payback | — | 6–18 months | Depends on duty cycle and gas cost |

In tight delivery windows, the schedule risk reduction can be as valuable as direct fuel savings.

Future market opportunities and 2025+ trends: practical decarbonization for Pakistan’s steel and foundry ecosystem

Three forces will shape adoption in Pakistan. First, energy and emissions economics will continue to reward verifiable, incremental efficiency gains—especially those achievable without major rebuilds. Second, data-centric operations are spreading: plants now log O2 residuals, NOx/CO, and fuel trims, enabling continuous optimization once hardware is stable. Third, supply-chain resilience is becoming strategic; hybrid material specs, local stocking, and technology transfer reduce FX and lead-time exposure.

As a combustion specialist observed at a regional seminar, “The cheapest kilojoule is the one you don’t burn because your flame is stable.” (Reference: South Asia Thermal Processing Seminar, 2024). Building on this, Pakistan’s metallurgy plants can layer analytics on top of SiC-stabilized hardware, extracting more value from every furnace hour while strengthening audit narratives.

Frequently asked questions

What practical gains can I expect from SiC burner tiles and throats?

You can typically operate with lower excess air for the same stability, reduce hotspots (cutting NOx), and extend campaign life in dusty, abrasive atmospheres—leading to shorter soaks and lower fuel per ton.

How do I choose between SSiC and SiSiC for hot parts?

Use SSiC for the hottest, most shock- and abrasion-exposed components where geometry drift is most damaging. SiSiC is an excellent balance for liners and transition zones.

Can I retrofit without changing my gas train or PLC?

In most cases, yes. We match OEM interfaces and integrate closed-loop O2 to your existing PLC/SCADA, adding CO trim where beneficial.

Will low-NOx designs hurt heat transfer?

With proper staging and internal recirculation, you can lower peak flame temperature (reducing NOx) while preserving convective/radiative heat transfer to the load—especially when geometry is held by SiC parts.

What documentation supports ISO and buyer audits?

Lot certificates for SiC materials (density, porosity, strength, shock tests, dimensions), burner/control data sheets, commissioning and O2/NOx logs, and maintenance records.

How do upgrades affect maintenance strategy?

Geometry-stable hot parts extend intervals; matched sets and seat finishes reduce micro-chipping. Controls tuning decreases nuisance alarms and emergency interventions.

Is local stocking or technology transfer available in Pakistan?

Yes. We offer distributor partnerships, safety-stock programs, and full technology transfer and factory establishment services for qualified partners.

How do systems handle power cuts and restarts?

Ramp-rate logic and warm-restart sequences, combined with shock-tolerant SSiC, minimize thermal shocks. Flames stabilize faster with less overshoot.

What about dual-fuel or variable gas quality?

Staged air and robust mixing designs cushion Wobbe swings; closed-loop O2 maintains targets despite composition changes.

How long is typical lead time?

Lead time depends on geometry and grade; we plan phased deliveries and customs-ready documentation to protect critical schedules.

Making the right choice for your operations

Upgrading industrial furnace burners and hot-zone components with SiC is not merely a materials choice—it is a process stability decision. Stable flame geometry and predictable thermal fields unlock energy savings, emissions control, and metallurgical consistency. With Sicarbtech’s integrated portfolio—SiC grades, burner engineering, controls integration, and turnkey technology transfer—Pakistani plants can implement improvements quickly, document them credibly, and sustain them across campaigns.

Get expert consultation and custom solutions

Share your furnace type, duty cycle, target O2/NOx, and recent fuel/quality metrics. Sicarbtech will propose a grounded upgrade plan—SiC component mapping, low-NOx burner configuration, closed-loop O2 integration, and a stocking strategy—complete with ROI modeling and implementation timelines.

Sicarbtech — Silicon Carbide Solutions Expert

Member, Chinese Academy of Sciences (Weifang) Innovation Park

10+ years of SiC customization | 19+ enterprises supported

Email: [email protected] | Phone: +86 133 6536 0038

Article metadata

Last updated: 2025-10-10

Next scheduled review: 2026-01-15

Content freshness indicators: reflects 2025 Pakistan metallurgy context; includes reheat/foundry heat-treatment use cases; current R-SiC/SSiC/RBSiC/SiSiC portfolio; alignment with ISO 9001/14001/45001 documentation; emphasis on low-NOx, closed-loop O2, and SiC geometry stability.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.