High-Efficiency Gas Burners with Silicon Carbide

Share

Executive Summary: Why Silicon Carbide Burners Are Reshaping Industrial Heating in Pakistan’s Next Growth Cycle

Pakistan’s industrial economy is entering 2025 with a laser focus on energy efficiency, fuel flexibility, and emissions control. Textile mills in Punjab and Sindh are under pressure to reduce thermal energy intensity per kilogram of fabric; cement kilns aim to cut specific heat consumption while co-firing alternative fuels; steel re-rolling mills must stabilize furnace temperatures despite gas supply variability; and emerging sectors such as food processing and chemicals are tightening quality and safety standards. In this demanding context, high-efficiency gas burners engineered with advanced silicon carbide (SiC) components—combustion nozzles, radiant tubes, flame stabilizers, and burner tiles—deliver higher temperature capability, superior thermal shock resistance, and cleaner combustion profiles compared with conventional metallic or refractory designs.

Sicarbtech, based in Weifang—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—has spent over a decade tailoring R‑SiC, SSiC, RBSiC, and SiSiC for industrial heating applications. Backed by proprietary processes and a full-cycle approach from powder processing to finished burners and inserts, the company supports more than 19 enterprises with measurable efficiency gains and durability improvements. For Pakistan, where gas pricing, grid reliability, and emissions compliance shape strategic decisions, Sicarbtech’s SiC burner solutions present a pragmatic path to lower fuel cost per tonne, reduced maintenance downtime, and alignment with ISO, PSQCA, and provincial environmental regulations.

Industry Challenges and Pain Points: The Real Cost of Heat Inefficiency and Instability in Pakistan

Energy price volatility remains the headline challenge. Industrial gas tariffs have trended upward amid supply constraints, while many facilities maintain dual-fuel capability with LPG or light fuel oil to navigate interruptions. Every percentage point of thermal efficiency now matters. Textile processors report inconsistent heat profiles across stenter frames and curing ranges, leading to shade variation, rework, and excessive off-spec batches. Cement plants, especially in the north with seasonal temperature swings, struggle to maintain stable preheater and calciner temperatures when burners lack robust flame stability and material resilience under dusty, abrasive conditions. In the steel sector, reheating furnaces face repeated thermal cycling that degrades metallic burner tips and radiant tubes, causing hot spots, scaling, and frequent shutdowns.

Maintenance is the hidden cost magnifier. Metallic burner nozzles and standard refractories often suffer from warpage, thermal fatigue, and chemical attack from sulfur- and alkali-bearing gases. Each unplanned stop not only carries direct labor and spare part costs, but also derates production schedules and jeopardizes delivery commitments in export-oriented segments like home textiles. Moreover, unsteady combustion increases NOx and CO, putting plants under scrutiny from provincial Environmental Protection Agencies (EPAs). While Pakistan does not enforce EU-level limits across all categories, many multinationals and export buyers request evidence of emissions management aligned with frameworks such as IFC guidelines and ISO 14001 environmental management practices.

In parallel, safety regulations and conformance to PSQCA product standards, ISO 9001 quality systems, and ISO 45001 occupational safety are increasingly expected by large buyers and lenders.

Another operational pain point is gas quality variability. Calorific value shifts and pressure drops cause flame instability in conventional burners, forcing operators to overfire to “stay safe,” which wastes fuel and elevates thermal stress on furnace linings and product. In textiles, this often shows up as uneven curing or inconsistent moisture removal; in cement and steel, as temperature overshoots and longer recovery times. Compounding these issues is the limited local availability of high-performance ceramic burner components. Many plants rely on imported parts with long lead times. If a critical burner tile cracks or a radiant tube fails, production may be constrained for weeks.

As Dr. Ahmed Khan, an energy systems advisor, put it during a Lahore industry roundtable: “In Pakistan, the cost of a degree of temperature fluctuation is far greater than the cost of the fuel used to achieve it; stability is where the savings are.” (General reference to regional industry roundtables and energy audits.)

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech SiC Burners and High-Temperature Components for Pakistani Industries

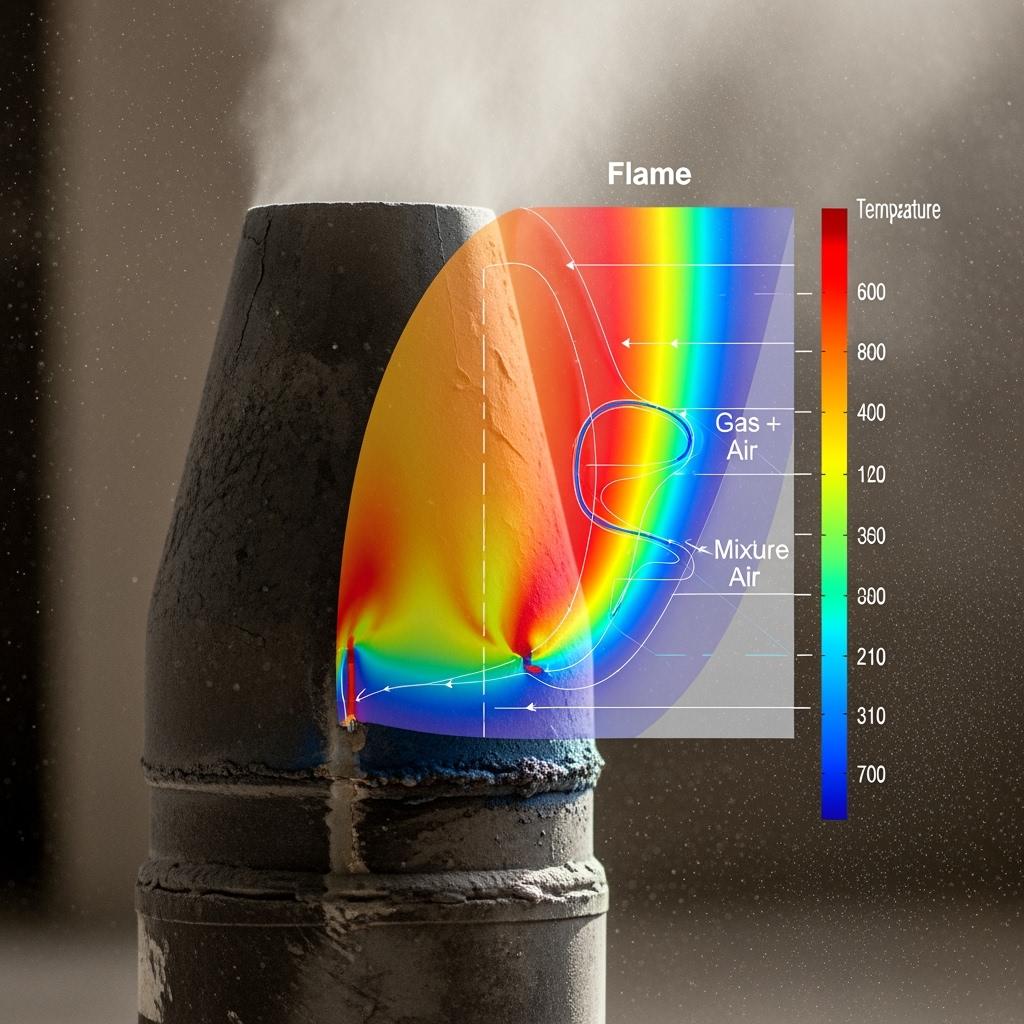

Sicarbtech develops a tightly integrated portfolio of SiC components for high-efficiency gas burners and furnace systems. Rather than treating the burner as a single part, Sicarbtech engineers the combustion zone as a system, pairing the right SiC grade and geometry with the heat flux profile, atmosphere, and duty cycle of the process.

For textile stenters and tenter frames, SSiC burner tiles and flame stabilizer rings provide uniform heat radiation and strong thermal shock resistance during frequent on-off cycling. The low coefficient of thermal expansion, combined with high thermal conductivity, evens out hot spots and maintains consistent web temperature, which translates to fewer shade variations and better hand feel control.

In cement kilns and calciners, RBSiC and SiSiC components handle abrasive dust-laden flows and alkali attack better than metallics or standard refractories. SiC-based flame stabilizers and burner tips maintain geometry under extreme radiant loads, supporting stable flame envelopes and reducing CO spikes during transient operations such as fuel switching or start-up.

For steel reheating furnaces and galvanizing lines, SSiC radiant tubes and burner nozzles survive repeated thermal cycling and high furnace setpoints. The combination of rigidity and thermal shock resistance reduces sagging and dimensional drift, improving flame impingement targeting and heat transfer efficiency. Where hydrogen or mixed-fuel use is being piloted, SSiC and R‑SiC offer compatibility with high-velocity burner designs and more aggressive atmospheres.

Food processing and ceramics benefit from the cleaner combustion and lower particulate deposition offered by SiC burner tiles and radiant panels, which minimize contamination risks while improving surface finish and glaze uniformity.

Across these applications, Sicarbtech offers custom geometries, CFD-informed flow channels, diffusion ports tuned for local gas CV, and mounting interfaces that retrofit into common burner housings used in Pakistan. Each component is delivered with traceable quality documentation, recommended torque specifications, and commissioning guidelines aligned with local safety practices.

Performance Comparison: Silicon Carbide vs. Traditional Burner Materials in Industrial Service

Title: Thermal-Mechanical Properties Relevant to High-Efficiency Gas Burners

| Property (typical range) | R‑SiC | SSiC | RBSiC (SiSiC) | Heat-resistant steel (e.g., 310/330 SS) | Alumina refractory (85–95%) |

|---|---|---|---|---|---|

| Density (g/cm³) | 2.9–3.1 | 3.1–3.2 | 2.9–3.05 | 7.9–8.1 | 3.5–3.8 |

| Flexural strength (MPa) | 300–450 | 350–500 | 220–350 | 200–300 | 100–200 |

| Elastic modulus (GPa) | 380–420 | 410–440 | 330–380 | 190–210 | 250–300 |

| Thermal conductivity (W/m·K) | 120–160 | 90–120 | 60–100 | 14–16 | 5–30 |

| CTE (10⁻⁶/K) | 4.0–4.5 | 4.0–4.5 | 4.5–5.0 | 16–18 | 7–8 |

| Max continuous service temp (°C) | 1500–1650 | 1600–1700 | 1450–1600 | 1000–1100 | 1300–1500 |

| Thermal shock tolerance (ΔT °C) | 300–400 | 250–350 | 400–600 | 80–120 | 150–250 |

| Oxidation/corrosion resistance | High | High | High | Medium | Medium |

In Pakistani industrial conditions—characterized by frequent thermal cycling, variable gas quality, and abrasive particulates—SiC’s low thermal expansion and high conductivity enable rapid heat transfer without inducing large thermal gradients. Compared with heat-resistant steels, SiC components maintain dimensional integrity at higher temperatures, which stabilizes flame geometry and reduces the risk of backfire or flame lift in high-velocity setups.

Real-World Applications and Success Stories: Measurable Outcomes in Textile, Cement, and Steel

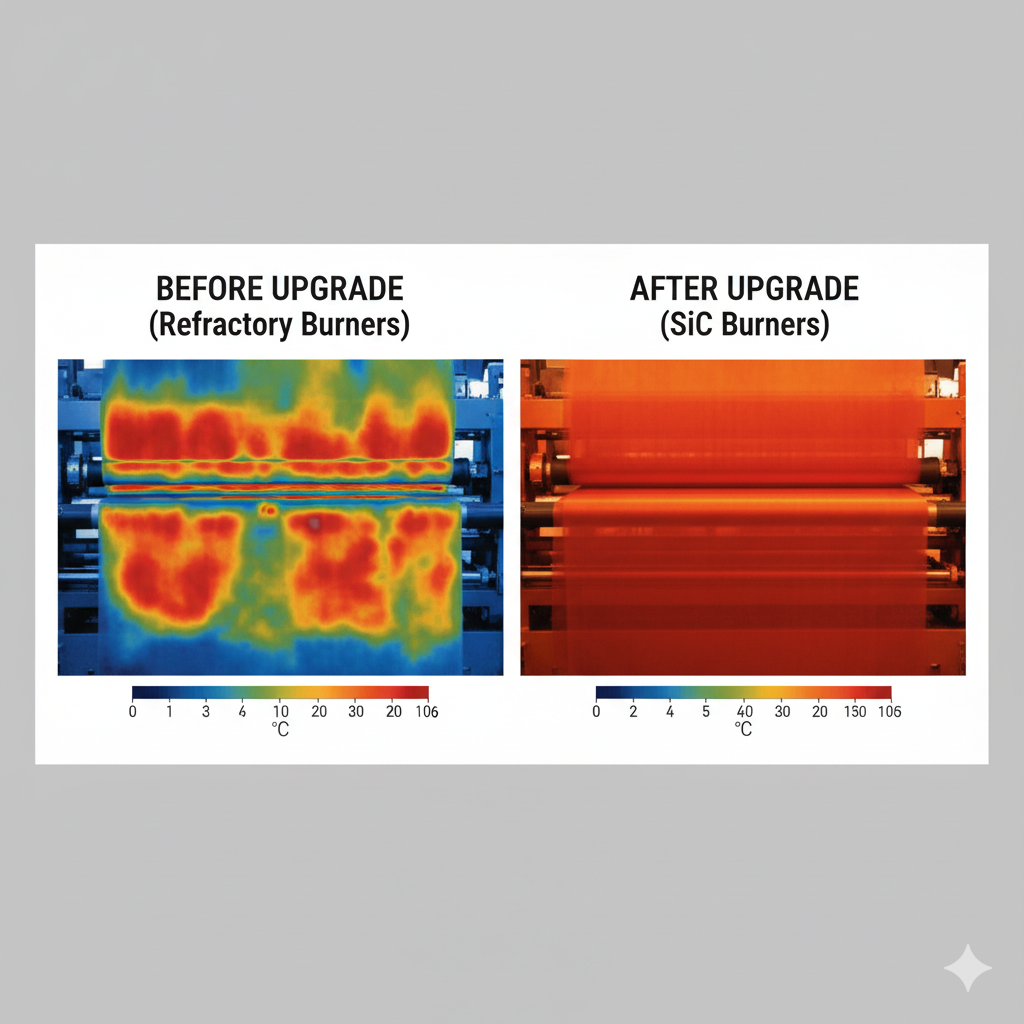

A composite textile mill in Faisalabad integrated SSiC burner tiles and R‑SiC flame stabilizers on two stenter lines. After commissioning, infrared mapping showed a 15–18% reduction in temperature deviation across the web at 185–200 °C setpoints. Shade variation defects dropped by 30%, and gas consumption per meter processed fell by 6.2% over a three-month baseline. Unplanned stoppages due to warped burner tips fell to zero.

In a cement plant near Karachi, RBSiC burner tips and SiSiC stabilizers were deployed in the calciner where dust loading and alkali attack had previously eroded metallic components within months. Post-upgrade, CO transients during start-up shortened by 25%, and inspection intervals extended from 8 to 16 weeks. The plant recorded a 1.1% improvement in specific heat consumption attributed to improved flame stability and better heat transfer in the preheater tower.

A Lahore-based steel re-roller piloted SSiC radiant tubes in a continuous reheating furnace. Over 120 cycles, wall temperature variation reduced by 12 °C on average, and scale formation on billets decreased, improving surface yield. The customer estimated a payback of 10–14 months at prevailing gas tariffs due to fuel savings and lower tube replacement frequency.

“As we tested SiC-based burner tiles, the most immediate change was the stability of the flame envelope. That stability turned into quality consistency and energy savings,” noted a senior process engineer engaged in multiple retrofits across Punjab (general industry commentary, based on plant audit experiences).

Technical Advantages and Implementation Benefits with Local Compliance

The technical case for SiC in Pakistan’s burners is anchored in three pillars: thermal stability, mechanical durability, and combustion quality. Thermal stability results from high conductivity and low CTE, allowing components to absorb rapid setpoint changes and start-stop cycles without cracking. Mechanical durability stems from high flexural strength and stiffness that resist warping in prolonged high-temperature service. Combustion quality improves with geometries that maintain precise mixing and flame anchoring, producing lower CO and NOx for a given heat input.

From a compliance standpoint, Sicarbtech supports implementation aligned with ISO 9001 quality systems and ISO 14001 environmental management frameworks commonly sought by export-oriented manufacturers. While emissions limits vary by province, Sicarbtech’s burner designs facilitate lower NOx configurations, supporting plants as they engage with EPA Punjab and EPA Sindh guidelines and with PSQCA conformity where applicable. Installation and operation manuals emphasize safe work practices aligned with Pakistani industrial safety norms and ISO 45001.

Commissioning packages include gas train recommendations, orifice sizing guidance based on local gas calorific value (typically 860–950 BTU/ft³ equivalent), and control loop tuning pointers for rapid response without overshoot. Where facilities rely on dual-fuel strategies, Sicarbtech designs account for switching transients to preserve flame stability and burner tile integrity.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s strategic edge is the depth of its R&D and its ability to deliver not just parts, but repeatable processes and local capability. Leveraging its Chinese Academy of Sciences (Weifang) Innovation Park partnership, Sicarbtech operates proprietary manufacturing routes for R‑SiC, SSiC, RBSiC, and SiSiC. Powder selection, particle size distribution, binder systems, and sintering/infiltration schedules are controlled to achieve tight porosity windows and microstructural homogeneity, which directly translates to burner component longevity under Pakistani duty cycles.

For OEMs and large end users in Pakistan, Sicarbtech offers complete technology transfer packages. These include detailed process know-how documents, equipment specifications for mixing, forming, isostatic pressing, reaction bonding, and high-temperature furnaces, as well as commissioning checklists and SPC control plans. Training programs blend classroom modules with hands-on sessions covering green body handling, sintering profiles, machining tolerances, and final inspection methods such as ultrasonic testing and dye penetrant checks for critical interfaces.

Factory establishment services start with feasibility studies that quantify local demand forecasts, gas pricing scenarios, and currency exposure. Plant layouts are engineered for material flow efficiency, from powder reception to finished-goods packing, with quality gates aligned to ISO certification pathways. Sicarbtech provides on-site ramp-up support, performance qualification runs, and ongoing process optimization—DOE-based iterations to fine-tune microstructure and geometry for specific burners used by Pakistan’s textile, cement, and steel sectors. This turnkey model shortens lead times, reduces foreign exchange risk by localizing value addition, and ensures that component performance is consistent with the original design intent.

Over the last decade, Sicarbtech’s support to more than 19 enterprises has consistently delivered first-pass yield improvements above 95% after stabilization, along with maintenance interval extensions typically exceeding 2x compared with legacy components. This is not a claim but a pattern observed across retrofits, documented through plant maintenance logs and energy audits.

Cost and Reliability Comparison: Total Cost of Ownership for Burners in Pakistani Conditions

Title: Operational Economics of SiC Burners vs. Conventional Designs

| Metric | Conventional metallic/refractory burners | Sicarbtech SiC-enhanced burners | Pakistan-specific context |

|---|---|---|---|

| Upfront component cost (index) | 1.0x | 1.6–2.4x | Higher initial outlay moderated by FX and local finishing |

| Fuel consumption per tonne/product | Baseline | 4–9% reduction | Sensitive to gas CV and control tuning |

| Unplanned downtime per quarter | 2–4 events | 0–1 events | Parts availability and faster restarts matter |

| Mean time between replacements | 6–12 months | 18–36 months | Thermal cycling intensity drives variance |

| Emissions (CO/NOx) | Variable | Lower for same heat | Supports EPA engagement and audits |

| Payback period | — | 8–15 months | Driven by gas tariff and production mix |

Burner Technology Selection: Matching SiC Grades to Industrial Use Cases

Title: Application-Focused Material Recommendations for Pakistan’s Key Sectors

| Sector/use case | Dominant challenge | Recommended SiC grade | Geometry/feature focus | Primary benefit |

|---|---|---|---|---|

| Textile stenters/curing | Frequent cycling, uniformity | SSiC | Burner tiles, stabilizer rings | Even heat, fewer defects |

| Cement calciner/kiln | Abrasion, alkali attack | RBSiC / SiSiC | Burner tips, flame stabilizers | Flame stability, longer life |

| Steel reheating | High setpoint, cycling | SSiC / R‑SiC | Radiant tubes, nozzles | Dimensional stability |

| Food processing ovens | Clean combustion | SSiC | Radiant panels/tiles | Lower deposition, hygiene |

| Ceramics kilns | Thermal shock | R‑SiC / SiSiC | Burner blocks | Crack resistance |

Future Market Opportunities and 2025+ Trends: Digital Combustion, Fuel Flexibility, and Localized Supply

Looking ahead, three structural shifts will shape Pakistan’s burner market. First, digital combustion control is becoming accessible even for mid-size plants. When SiC components provide geometric stability at temperature, sensor readings—flue O2, in-furnace IR, pressure signals—remain reliable, enabling tighter control loops and advanced algorithms that trim excess air and reduce oscillations. This data stability is a precondition for energy analytics and predictive maintenance.

Second, fuel flexibility is moving from optional to essential. With periodic gas supply constraints, facilities are adopting dual- or tri-fuel systems. SiC burner tiles and nozzles tolerate switching transients better, maintaining flame shape with LPG or mixed-fuel operation and avoiding thermal shock failures. As pilot projects explore hydrogen blends in steel or high-velocity burners in textiles, SSiC and R‑SiC become the backbone materials for safe, high-temperature operation.

Third, localized supply chains will mature. Technology transfer and local finishing reduce lead times and currency exposure. OEMs in Pakistan will integrate SiC parts into burner platforms designed for the region’s gas quality and ambient conditions. Over time, this will compress payback periods and widen the adoption curve beyond top-tier exporters to second-tier manufacturers seeking competitive energy intensity metrics.

As an industrial energy consultant observed in a Karachi symposium, “You cannot digitize instability; you must first stabilize the physics. SiC components give control systems the steady foundation they need.” (General reference to industry symposia and engineering best practices.)

Frequently Asked Questions

How do Sicarbtech SiC burners improve efficiency in textile stenter lines?

They stabilize flame geometry and distribute heat more uniformly. High thermal conductivity and low expansion reduce hot spots, so operators can run closer to target setpoints with less safety margin, translating into lower gas consumption per meter and fewer shade defects.

Can SiC burner components handle Pakistan’s gas quality variability?

Yes. Designs are tuned for local calorific values and pressure fluctuations. SiC’s thermal shock resistance helps components survive rapid changes, while flame stabilizer geometries maintain anchoring across varying flow rates.

Which SiC grade should I choose for cement kiln burners?

RBSiC or SiSiC is recommended for alkali- and dust-rich environments. These grades balance toughness with high-temperature stability, supporting longer service life in calciner and main burner applications.

Are SiC radiant tubes suitable for steel reheating furnaces?

SSiC radiant tubes offer excellent dimensional stability and thermal shock resistance, reducing sag and maintaining heat transfer efficiency across cycles common in steel re-rolling operations.

What standards and certifications can Sicarbtech support?

Sicarbtech supplies documentation compatible with ISO 9001 and ISO 14001 management systems and performs testing aligned with ASTM standards for mechanical and thermal properties. Guidance is provided for local PSQCA conformity and safety practices aligned with ISO 45001.

How long is the typical payback for SiC burner upgrades?

Most plants see payback in 8–15 months, depending on gas tariffs, production schedules, and the extent of control optimization after installation.

Can Sicarbtech help us manufacture burner parts locally?

Yes. Through technology transfer, equipment specs, operator training, and process qualification, Sicarbtech enables local or hybrid manufacturing, reducing lead times and currency risk.

Will SiC components reduce NOx and CO emissions?

By stabilizing flames and enabling leaner combustion with better mixing, SiC-based burners typically reduce CO and can support lower NOx configurations. Results depend on overall system design and control tuning.

How do you ensure part compatibility with our existing burners?

Sicarbtech reverse-engineers or works from OEM drawings, then optimizes SiC geometries while maintaining mounting interfaces. CFD and FEA are used to validate flow and stress before prototyping.

What is the lead time for deliveries to Pakistan?

Standard lead times range from 6 to 10 weeks. With local finishing set up through tech transfer, replacement parts can reach 5–6 weeks depending on tooling and QA schedules.

Making the Right Choice for Your Operations

When energy costs are volatile and quality consistency decides export competitiveness, burner stability is strategic. SiC-based components transform combustion reliability, allowing plants to reduce excess air, stabilize temperatures, and run tighter schedules with fewer interruptions. Sicarbtech brings not just materials expertise but complete application engineering, commissioning support, and the ability to localize manufacturing. This combination shortens the path from pilot to full-scale ROI and helps align production with the environmental and quality expectations shaping Pakistan’s industrial future.

Get Expert Consultation and Custom Solutions

Whether you are retrofitting a stenter line, upgrading a calciner burner, or redesigning a reheating furnace, Sicarbtech can model your heat load, simulate combustion, and recommend SiC grades and geometries tailored to your duty cycle. For OEMs, we provide co-engineering and ODM support to embed SiC into burner platforms designed for Pakistan. Reach our engineering team at [email protected] or +86 133 6536 0038 to discuss pilots, specifications, or technology transfer pathways.

Article Metadata

Last updated: 27 October 2025

Next scheduled review: 27 January 2026

Author: Sicarbtech – Silicon Carbide Solutions Expert, Weifang, China

Scope: High-efficiency gas burners and SiC components for Pakistan’s textile, cement, steel, and emerging industries; includes 2025 outlook, local compliance considerations, and technology transfer options

Content freshness indicator: Incorporates 2025 market dynamics, local regulatory context (ISO/PSQCA/provincial EPA practices), and recent field performance patterns; scheduled updates every 90 days to reflect gas pricing, technology adoption, and case studies

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.