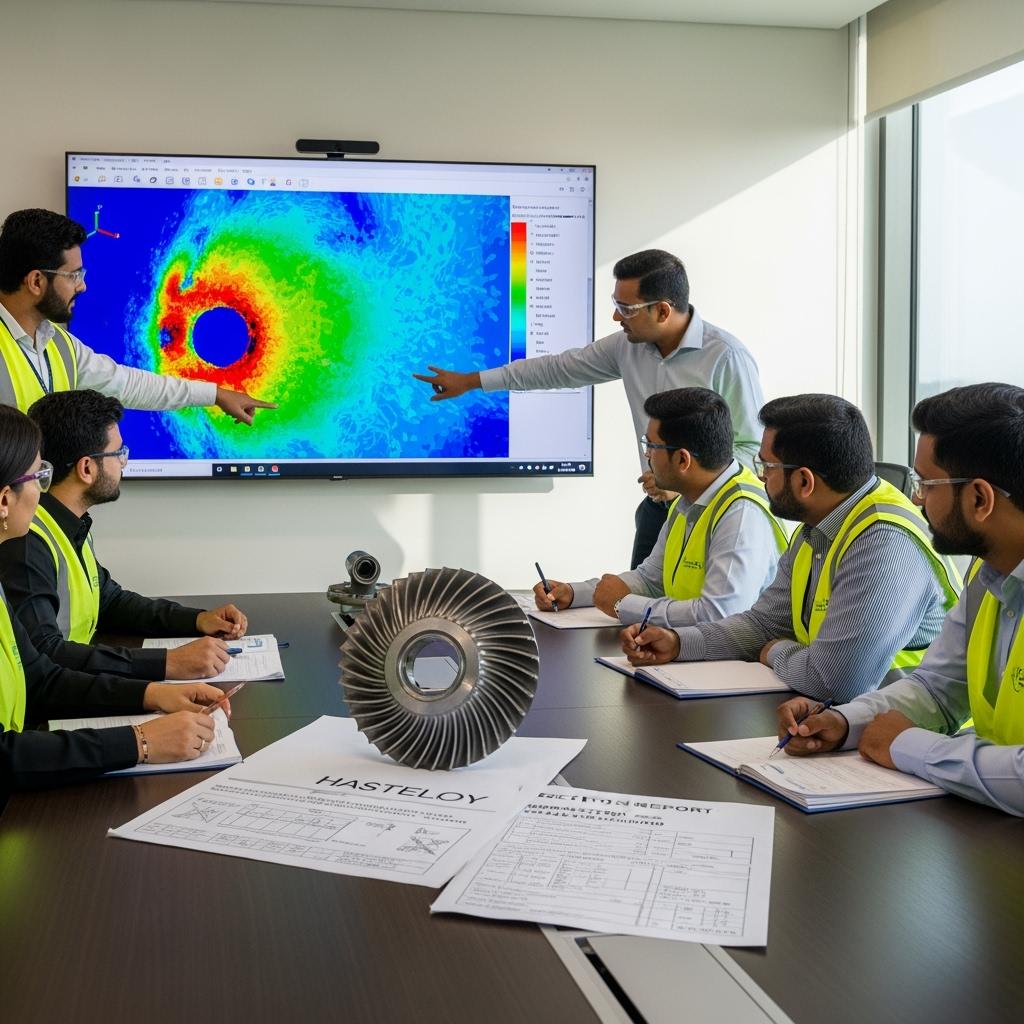

Hastelloy Cantilever Impellers for Industrial Pumps in Pakistan

Share

Executive overview: 2025 outlook for corrosion‑resistant pump performance in Pakistan’s process industries

Pakistan’s industrial base is entering a decisive phase in 2025. Volatility in energy pricing, mounting water‑treatment demands, and tighter environmental enforcement are converging with export‑driven growth in textiles and a sustained clinker output in cement. Across these sectors, unplanned downtime is increasingly expensive in PKR terms due to imported spares, shipping lead times, and exchange‑rate swings. In this context, Hastelloy cantilever impellers—precision‑engineered nickel alloy impellers designed for non‑overhung shaft support in corrosive services—are emerging as a dependable lever to stabilize flow, extend mean time between failures, and reduce total cost of ownership in harsh chemistries where stainless steels quickly pit or crevice‑corrode.

Sicarbtech, headquartered in Weifang City—the silicon carbide and advanced materials manufacturing hub of China—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings a full‑cycle solution model to Pakistan’s OEMs and plant operators. With over 10 years of customization experience and more than 19 enterprises supported, we integrate materials engineering, foundry excellence, precision machining, and, where needed, technology transfer and factory establishment.

While our heritage includes advanced silicon carbide (R‑SiC, SSiC, RBSiC, SiSiC) for extreme wear and temperature, our Hastelloy cantilever impeller portfolio is engineered to address the corrosion, erosion, and chloride stress corrosion cracking realities faced by local textile dye houses, cement plants’ scrubber and slurry circuits, steel pickling lines, and municipal and industrial wastewater facilities.

Pakistan’s industrial challenges and pain points: why cantilever impellers matter now

If we step into a Faisalabad dyeing unit, the chemical reality is unforgiving. Chloride‑rich baths, oxidizers, and dyes cycle across temperature ranges that punish martensitic and even austenitic stainless steel. Cavitation from fluctuating suction head during peak shifts further chips away at blade leading edges, turning performance curves theoretical. Meanwhile, in cement operations around Punjab and Khyber Pakhtunkhwa, gypsum and limestone slurry loops push silica‑laden particulates through pump inlets, creating erosive wear that can strip protective passive films from lesser alloys. The problem is not only material selection; it is how the impeller geometry handles solids loading, vapor pockets, and localized turbulence.

In the steel sector, pickling lines handling HCl or mixed acid solutions face classic pitting and transgranular attack, especially at welds and sharp crevices around blade roots. Operators often overspecify flow to maintain production, masking hydraulic inefficiencies and accelerating corrosion by increasing velocity at the blade’s suction side. Wastewater plants in Karachi and Lahore, dealing with variable pH and intermittent oxidant dosing, experience micro‑pitting that seeds catastrophic failure once crevices establish at the hub‑blade interface. The operational implications are significant: each unscheduled stop can translate into lost export shipments, clinker backlog, or regulatory non‑compliance penalties for effluent discharge.

Cost dynamics amplify the pain. Imported stainless spares may appear economical on a unit basis, yet the PKR denominator expands when factoring in freight, duties, and the opportunity cost of downtime awaiting customs clearance. Additionally, Pakistan’s NEQS (National Environmental Quality Standards) enforcement has tightened, particularly on textile effluent and cement dust/particulate capture, pushing plants to keep scrubbers and neutralization systems continuously online. Non‑compliance triggers fines and, more importantly, jeopardizes international brand audits that many exporters must pass.

Local regulatory and standards context also matters. OEMs and EPCs frequently reference API 610 for centrifugal pump design, ISO 9906 for hydraulic performance acceptance, and ASTM material standards for metallic composition and mechanical properties. Yet few suppliers align the entire chain—from melt chemistry to NDE to balancing—to these frameworks. As a maintenance manager from a Lahore chemicals plant remarked at a regional reliability forum, “We don’t just need a better alloy; we need a better geometry, a better QA trail, and a supplier who can document both” (reference: general industry conference proceedings and reliability engineering literature).

Moreover, the skills gap in some workshops leads to poor balancing and surface finish inconsistency, which in turn exacerbates vibration, invites cavitation, and shortens bearing and seal life. In contrast, cantilever architectures remove the bearing in the wet end, reducing seal complexity and eliminating a common failure mode. Still, the impeller must be designed to manage shaft deflection and hydraulic thrust without the support of a close‑coupled overhung bearing. This is where Sicarbtech’s combination of alloy know‑how, blade‑root stress relief, and computational flow optimization translates into measurable uptime.

Sicarbtech’s advanced solutions portfolio: Hastelloy cantilever impellers engineered for Pakistan’s chemistries

Sicarbtech’s cantilever impellers begin with alloy selection aligned to the specific chemistry and temperature window. Hastelloy C276 remains the workhorse for chloride‑rich oxidizing environments, resisting pitting, crevice corrosion, and stress corrosion cracking. For reducing acid media, C22 can offer improved resistance to certain mixed acid formulations, while for high‑chloride, oxidizing bleach streams common in textile processing, G30 or custom nickel‑molybdenum blends may be recommended after coupon testing. We calibrate composition per ASTM B574/B575 and verify heat treatment and grain size to ensure uniform corrosion resistance.

Geometry is treated as a performance variable rather than an afterthought. Leading edge thickness, wrap angle, and blade count are optimized using CFD to minimize recirculation at expected flow turndown ratios—a frequent reality in batch dyeing and variable kiln‑bypass scrubber duties. Blade roots receive generous fillets and, where appropriate, pocket relief to reduce crevice propensity. Hub bores are machined with controlled surface roughness and roundness tolerances to facilitate precise fits on cantilever shafts, while keyways are chamfered to prevent stress risers.

Manufacturing quality flows through precision investment casting or 5‑axis machining from forged billets depending on size and required surface integrity. We employ solution annealing and rapid quench to restore corrosion resistance post‑fabrication, followed by dye penetrant testing of blade surfaces, ultrasonic inspection of hubs for inclusions, and ISO 1940‑1 G2.5 balancing or better for critical services. For slurry services in cement and steel, we blend geometry with hardfacing strategies only where metallurgically compatible; typically, Hastelloy itself suffices when velocities and solids content are controlled within design limits.

Sicarbtech’s heritage in silicon carbide engineering enhances our approach to mixed corrosion‑erosion problems. In several Pakistani scrubber and neutralization skids, we integrate SiC wear rings or SSiC liners upstream to condition flow and reduce erosive particle impact on the impeller’s suction side. This combined materials strategy—Hastelloy for corrosion, SiC for abrasion—has extended service intervals without over‑complicating the pump assembly.

Performance comparison: Hastelloy cantilever impellers versus stainless and duplex alternatives in local conditions

| Corrosion and performance comparison in common Pakistani services | Hastelloy C276 Cantilever Impeller | 316L Stainless Impeller | Duplex 2205 Impeller | Rubber‑Lined Ductile Iron Impeller |

|---|---|---|---|---|

| Chloride SCC resistance (ppm Cl− at 80–100°C) | Excellent up to high chlorides | Poor > 100 ppm | Moderate to good | Not applicable (liner dependent) |

| Pitting resistance equivalent (PREN) | ~69 | ~25 | ~35 | N/A |

| Crevice corrosion in oxidizing bleach (textile) | Excellent | Poor | Moderate | Liner degradation risk |

| HCl pickling line (steel) | Good (verify concentration/temperature) | Poor | Moderate | Poor |

| Slurry erosion (cement scrubbers) | Good at design velocities | Fair | Good | Good initially, liner wear |

| ISO 1940‑1 balance achievable | G2.5 or G1 | G6.3–G2.5 typical | G6.3–G2.5 | G6.3 |

| Expected MTBF in mixed duty (months) | 18–36 | 6–12 | 9–18 | 6–12 |

| Total cost of ownership (24 months, relative) | 0.8–0.9 | 1.0–1.2 | 0.9–1.1 | 1.0–1.3 |

By aligning alloy and geometry to Pakistan’s process realities, Hastelloy cantilever impellers consistently outperform stainless and often duplex options, particularly where chlorides and oxidants coexist and operating cycles are variable.

Real‑world applications and success stories in Pakistan

When a Lahore textile processor struggled with frequent impeller failures in hypochlorite‑rich bleaching baths, a switch to Sicarbtech Hastelloy C276 cantilever impellers with a redesigned blade wrap angle and increased leading‑edge radius reduced hydraulic shock and eliminated the frequent pitting seen on 316L. Over a 14‑month period, the plant reported a 47% reduction in unscheduled pump downtime and a 9% decrease in specific energy consumption due to better hydraulic efficiency retained over time. The maintenance supervisor summarized the change: “We finally stopped treating impellers as consumables and started treating flow stability as an asset.”

In a major cement plant near Islamabad, kiln bypass scrubber circulation pumps faced erosive wear from dust‑laden slurry and corrosive condensate. Sicarbtech delivered C276 cantilever impellers paired with SSiC upstream wear components to smooth inflow. After 18 months, blade thickness loss measured ultrasonically was within 20% of baseline predictive models, and the scrubber’s differential pressure stayed within specification, avoiding the derating common during monsoon humidity spikes.

A Karachi steel pickling line using HCl at elevated temperatures implemented C22 impellers with enhanced crevice relief at blade roots. Post‑implementation, coupon corrosion rates fell below 1.5 mm/year equivalent, and cavitation signatures on vibration spectra diminished after we tuned NPSH margins and adjusted impeller diameter for the actual operating point, not the nameplate. This combination of metallurgy and hydraulic alignment delivered a payback in under 10 months given reduced scrap and fewer emergency imports.

Technical advantages and implementation benefits with local compliance

The cantilever architecture eliminates wet‑end bearings and mechanical seals in the fluid zone, reducing failure points in abrasive or crystallizing media. Hastelloy alloys, with high molybdenum and chromium content, stabilize the passive film even as chlorides and oxidants challenge lesser alloys, which is essential for NEQS compliance when pump upsets lead to concentration spikes. From an implementation standpoint, Sicarbtech’s ISO 9001‑aligned quality system ensures heat‑to‑part traceability, while our balancing and hydrotest documentation dovetail with API 610 and ISO 9906 acceptance protocols frequently referenced by Pakistani EPCs.

Furthermore, our installation support pays attention to the subtleties that often decide outcomes: ensuring adequate NPSHa through suction piping review, specifying realistic minimum continuous stable flow for batch operations, and confirming that VFD turndown strategies do not push the pump into severe recirculation. We also generate maintenance plans that align with typical Pakistani shift patterns, recommending inspection intervals that fit within Friday maintenance windows and seasonal outages around Ramazan where applicable, thereby minimizing production conflicts.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey edge

What differentiates Sicarbtech in Pakistan is not only metallurgy but a comprehensive, partner‑oriented model. Our R&D engine, reinforced through the Chinese Academy of Sciences (Weifang) Innovation Park, enables rapid alloy and geometry iterations, including pilot runs with test coupons exposed in your actual process stream. Proprietary manufacturing routes cover investment casting with refined feed systems to minimize porosity, HIP (hot isostatic pressing) where needed for critical integrity, and 5‑axis machining from forged stock for high‑precision small to mid‑diameter impellers.

For OEMs and large end users seeking resilience against FX risk and long import lead times, we offer complete technology transfer packages. These include detailed process know‑how, melt practice specifications, heat treatment cycles, NDE procedures, tool lists, and equipment specifications down to furnace size, balancing machines, and CMM requirements. Training programs for foundry technicians, machinists, and QA engineers are delivered on‑site, and we support factory establishment from feasibility studies and layout to commissioning and PPAP submission. Beyond start‑up, we maintain ongoing technical support, process audits, and continuous improvement workshops, ensuring the local plant hits yield, quality, and takt‑time targets.

Quality control is embedded at every step. Chemical composition is verified by OES and cross‑checked with wet chemistry for key heats. Mechanical properties are validated per ASTM E8/E21, while corrosion testing leverages ASTM G48 and application‑specific coupons. Dimensional control uses CMM inspection of hub bores, keyways, and blade chords, and every impeller is dynamically balanced to ISO 1940‑1 G2.5 or better. Certification support covers ISO 9001/14001/45001 pathways and integrates with Pakistani buyer documentation habits—material test certificates (MTC), hydrotest logs, performance curves, and spare parts lists formatted for local ERP ingestion.

Moreover, Sicarbtech pragmatically blends materials when it yields better lifecycle value. In abrasive loops, pairing Hastelloy impellers with SSiC or RBSiC wear components can reduce erosive attack without compromising corrosion resistance, particularly beneficial in cement scrubbers and certain textile effluent neutralization circuits. Our integration team ensures mechanical fits, thermal expansion allowances, and joint design prevent crevice formation—a known risk when dissimilar materials meet.

Detailed material selection and hydraulic configuration guidance for Pakistan’s services

| Application‑centric selection guide for Pakistani plants | Recommended Alloy/Design | Typical Temperature (°C) | Key Risks Mitigated | Configuration Notes |

|---|---|---|---|---|

| Textile bleaching (NaOCl, chlorides, oxidants) | Hastelloy C276 cantilever, high wrap angle | 25–70 | Pitting, crevice, SCC | Smooth leading edge, avoid dead zones; verify NPSHa at batch starts |

| Textile dyeing (mixed dyes, salt, temperature swings) | Hastelloy C22/C276, moderate blade count | 30–90 | Crevice, variable viscosity | VFD control; minimum stable flow definition |

| Cement scrubber slurry (dust, gypsum, chlorides) | Hastelloy C276 with SSiC wear ring | 35–60 | Erosion‑corrosion | Inlet conditioning; velocity cap to reduce erosive wear |

| Steel pickling (HCl) | Hastelloy C22, crevice‑relieved roots | 40–80 | Pitting, general corrosion | Coupon test for exact concentration; robust passivation |

| Industrial wastewater (variable pH, oxidants) | Hastelloy C276, conservative tip speed | Ambient–50 | Micro‑pitting, scaling | Periodic cleaning regime; surface finish Ra ≤ 1.6 μm |

This guidance is refined during application engineering sessions where we reconcile actual vs. datasheet conditions, reducing the common mismatch that shortens MTBF.

Future opportunities and 2025+ trends: positioning for resilience and ESG alignment

Looking beyond 2025, three forces stand out in Pakistan. First, export competitiveness hinges on reliability; buyers increasingly audit not only product quality but environmental compliance and traceability. Pumps that stay online in effluent treatment and scrubbers underpin both compliance and production stability. Second, digitization is accelerating. Plants are deploying vibration sensors and smart VFDs, and impellers that maintain balance and efficiency curves over longer periods yield cleaner data and better predictive outcomes. Third, the FX and logistics premium on emergency imports is unlikely to vanish. Local manufacturing capacity—either within Sicarbtech’s partner network or via transferred technology—will be a strategic hedge.

In cement, evolving emissions limits and clinker‑to‑cement ratio optimization will keep scrubbers and slurry circuits central, making corrosion‑resistant, erosion‑tolerant hydraulics a priority. Textiles will continue to grapple with stricter effluent limits and brand audits around ZDHC (Zero Discharge of Hazardous Chemicals), favoring materials that withstand oxidants without leaching problematic ions. Steel growth, tied to infrastructure and construction, will sustain acid handling duties with exacting uptime expectations. In all cases, suppliers who combine metallurgy, geometry, QA discipline, and documentation will win on lifecycle economics, not unit price.

Frequently asked questions

What makes a cantilever impeller different from a standard overhung design?

A cantilever impeller operates without bearings in the wet end, relying on the dry‑side support to handle radial and axial loads. This eliminates common failure points—seals and bearings exposed to corrosive or abrasive media—while demanding superior geometry, shaft stiffness, and balance to manage deflection. The result is higher reliability in harsh fluids.

Is Hastelloy C276 overkill for textile bleaching where 316L is currently used?

Not if your failure modes include pitting or crevice corrosion accelerated by hypochlorite and chlorides. C276’s high molybdenum and chromium content maintains passivity where 316L breaks down, extending service life and stabilizing efficiency. Many Pakistani dye houses have seen payback within a year due to fewer interruptions and lower energy drift.

How do you validate alloy authenticity and quality?

We provide full MTCs with heat numbers, OES chemistry, and mechanical properties per ASTM standards. NDE includes dye penetrant and ultrasonic testing, and dynamic balancing certification per ISO 1940‑1. Traceability is maintained from melt to finished impeller, with QR‑linked records if requested.

Can Sicarbtech support local manufacturing to reduce lead time and FX exposure?

Yes. We offer end‑to‑end technology transfer that includes process know‑how, equipment specs, operator training, and on‑site commissioning. We can also structure a hybrid supply model: initial imports to stabilize operations, followed by localized production ramp‑up with our ongoing technical oversight.

What about abrasive slurries in cement plants—won’t erosion negate corrosion benefits?

Erosion can be managed by controlling velocity, optimizing blade geometry, and conditioning inflow. Where solids are aggressive, we integrate SSiC wear rings or liners upstream to reduce particle energy before impact. This combined approach preserves the corrosion advantage of Hastelloy while handling abrasion.

Are your impellers compliant with API 610 and ISO 9906 requirements?

We design and document to align with API 610 concepts and provide hydraulic acceptance testing per ISO 9906 tolerance classes as required by the project. Balancing follows ISO 1940‑1, and we meet documentation expectations common to Pakistani EPCs and large industrial buyers.

What information do you need to propose the right impeller?

Provide fluid composition, temperature, pH, oxidants, solids content, flow and head at operating point, NPSHa, current failure modes, and any vibration data. Photos of the existing impeller and pump data plate help us accelerate a fit‑for‑purpose recommendation.

How fast can you deliver to Pakistan?

Standard lead times range from 5 to 10 weeks depending on size and complexity. For urgent cases, we can prioritize production and arrange consolidated shipments. Under a technology transfer program, local manufacturing can substantially compress lead times after ramp‑up.

Do you offer performance guarantees?

We offer performance commitments tied to agreed operating envelopes and installation conditions. Guarantees are backed by documented QA and, when applicable, coupon test data and pilot runs.

Can you integrate silicon carbide components with Hastelloy impellers?

Absolutely. Our SiC portfolio (R‑SiC, SSiC, RBSiC, SiSiC) complements impellers in erosion‑prone zones. We engineer interfaces to avoid crevice formation and differential expansion issues, delivering a cohesive assembly.

Making the right choice for your operations

Selecting a Hastelloy cantilever impeller is not a luxurious upgrade; it is a pragmatic response to corrosive, variable, and compliance‑sensitive services that define Pakistan’s process plants. When metallurgy, geometry, and QA converge, the payoff shows up as flow stability, clean vibration spectra, longer MTBF, and fewer compliance scares. Sicarbtech’s combination of alloy expertise, advanced manufacturing, and application engineering—reinforced by the option to localize production—gives maintenance and reliability teams a credible path to lower lifecycle cost without gambling on unproven tweaks.

Get expert consultation and custom solutions

Every duty has its own chemistry, velocity profile, and uptime imperative. Let Sicarbtech’s engineering team translate those realities into a Hastelloy cantilever impeller that is measurably better. Share your process data and failure history for a no‑obligation assessment and CFD‑backed proposal. Reach us at [email protected] or +86 133 6536 0038. For OEMs, we can co‑develop impeller families, qualify them through PPAP, and, if strategic, stand up local manufacturing through a structured technology transfer.

Engineering specification highlights for procurement and OEMs

| Procurement‑ready specifications for Hastelloy cantilever impellers | Sicarbtech Capability | Notes for Pakistan Projects |

|---|---|---|

| Alloys | Hastelloy C276, C22, custom Ni‑Mo‑Cr | Verified to ASTM B574/B575 |

| Diameter range | 80–600 mm | Larger sizes on request |

| Manufacturing | Investment casting, HIP optional; 5‑axis CNC from forged billet | Route selected by criticality |

| Heat treatment | Solution anneal and rapid quench | Corrosion resistance restoration |

| Surface finish | Ra ≤ 1.6 μm on hydraulic surfaces | Improves efficiency, reduces scaling |

| Balancing | ISO 1940‑1 G2.5 (G1 on request) | Documentation supplied |

| NDE | DPI on blades, UT on hubs | Acceptance criteria agreed |

| Documentation | MTC, balance cert, ISO 9906 test, installation guide | ERP‑friendly formats |

| Integration | SiC wear rings/liners (R‑SiC, SSiC, RBSiC, SiSiC) | Erosion mitigation |

| QA systems | ISO 9001/14001/45001 support | Local audit assistance |

As one regional reliability consultant often notes, “Superior metallurgy without superior geometry and QA is just expensive scrap.” Building on this, Sicarbtech aligns metallurgy, flow design, and process discipline to deliver durable results.

Article metadata

Last updated: 28‑Oct‑2025

Next scheduled update: 28‑Jan‑2026

Author: Sicarbtech Application Engineering Team

Region focus: Pakistan—textile, cement, steel, wastewater and emerging sectors

Contact: [email protected] | +86 133 6536 0038

Content freshness indicators: incorporates 2025 market conditions, NEQS compliance context, and API/ISO alignment; includes recent Pakistan‑based case insights; pricing and logistics assumptions calibrated to current FX and freight volatility. Continuous monitoring of regulatory and market shifts will inform the next revision.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.