High Temperature Cantilever Blades for Industrial Conveying Systems

Share

Executive summary: why high temperature cantilever blades are the quiet multiplier for Pakistan’s textile, cement, and steel lines

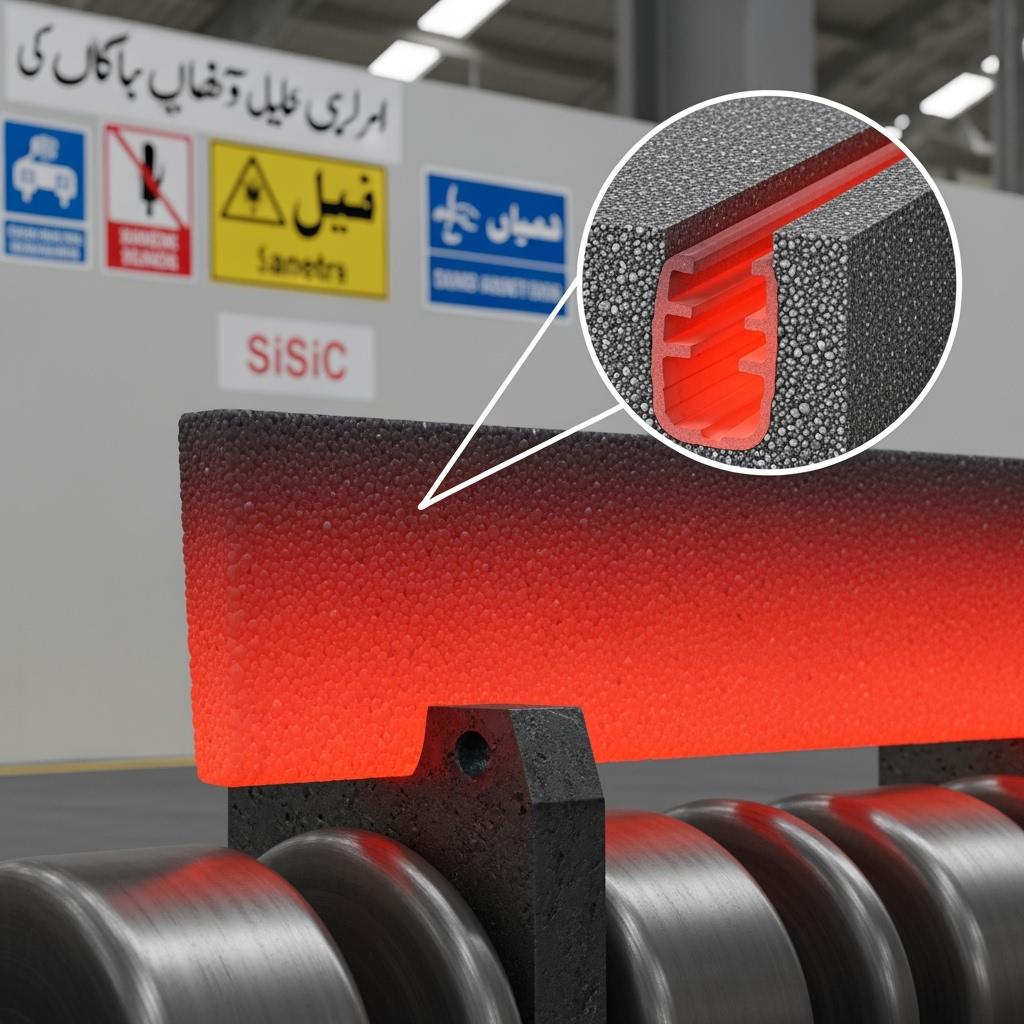

Factories across Pakistan are entering 2025 with clear marching orders: reduce specific energy consumption, stabilize quality, and harden supply resilience without large capital outlays. Roller hearths, shuttle kilns, roller conveyors in heat-treatment lines, and continuous dryers sit at the heart of this mission. High temperature cantilever blades made from advanced silicon carbide (SiC)—especially SiSiC and SSiC—are emerging as a small but decisive upgrade.

By holding geometry at temperature, resisting thermal shock, and shedding less mass under corrosive gases, SiC cantilever blades keep hearth decks level, heat profiles uniform, and cycles tight. The outcome is measurable: fewer unplanned stoppages, faster ramps, and more consistent product, whether you are firing ceramic components for cement plants, heat-treating steel parts for automotive supply chains, or drying coated textiles at precise temperatures.

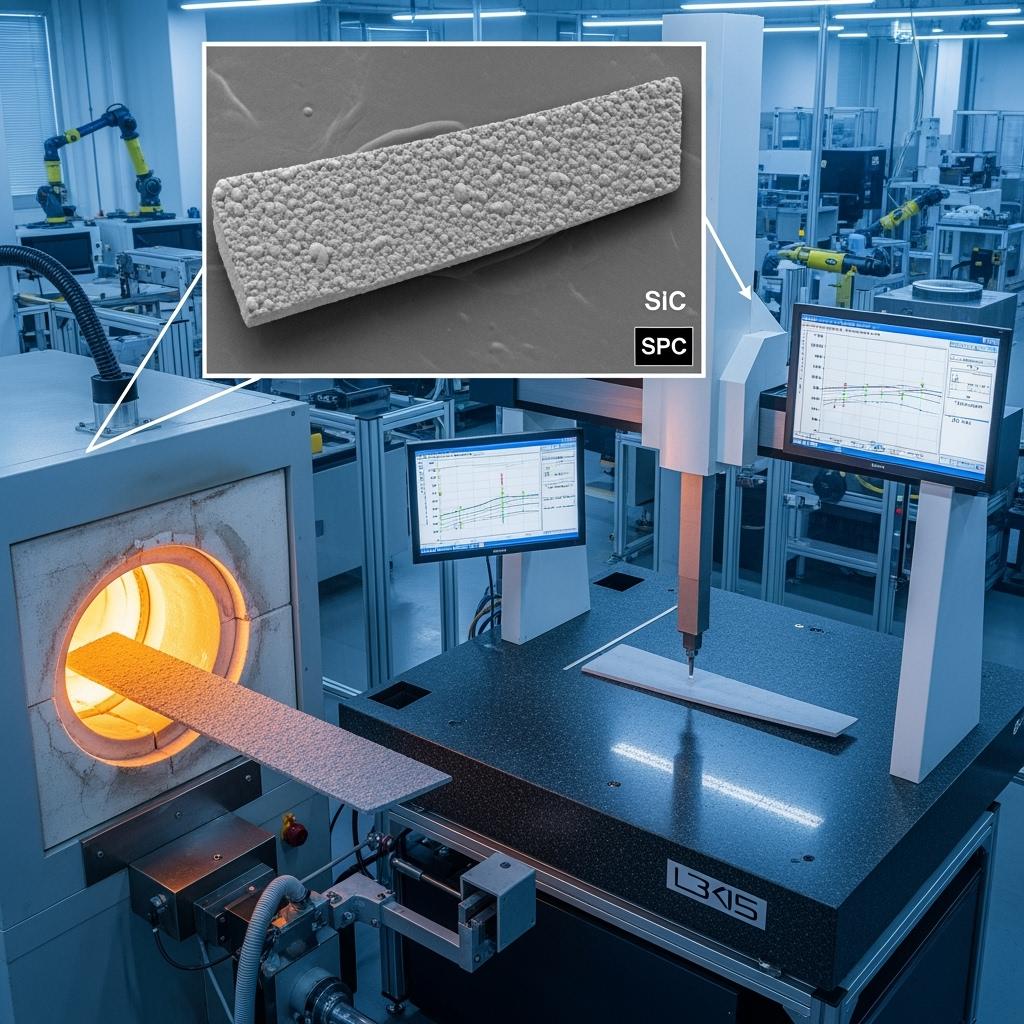

Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub and a member of Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of SiC customization experience to Pakistan’s industrial ecosystem. With a full-cycle model from material processing to finished components, and specializations in R‑SiC, SSiC, RBSiC, and SiSiC grades, Sicarbtech integrates material science with application engineering. Moreover, our turnkey services—custom manufacturing, factory establishment, and technology transfer—allow Pakistani OEMs and Tier‑1 suppliers to build local capability and shorten lead times while maintaining international quality standards.

Pakistan’s industry realities in 2025: where thermal variability, energy costs, and compliance collide

Pakistan’s manufacturing base is diversifying. Textile remains a cornerstone, yet cement and steel continue to scale, while automotive parts and engineered ceramics are expanding export ambitions. The common denominator is thermally intensive processes. In roller kilns used for ceramic setters and refractory parts for cement plants, small deviations in blade stiffness or hot planarity create uneven load support. This manifests as temperature hot spots, differential shrinkage, and warpage, forcing operators to lengthen soaks or raise setpoints by a few degrees to “force” uniformity. Those compensations are expensive, typically adding 5–12% to specific energy consumption and still risking inconsistent results.

Furthermore, the operating environment is not benign. Fuel switching, fluctuating gas quality, and variable excess air settings subject structural supports to repeated thermal shock. In cement-adjacent components, trace sulfur- and chlorine-bearing species increase corrosion. Steel heat-treatment lines impose cyclic loads and rapid ramps, while textile dryers demand flatness and alignment to avoid belt tracking issues and edge-to-center temperature skew. Conventional steel members creep, oxidize, and lose stiffness at relatively modest temperatures around 1,000–1,100°C. Alumina or mullite supports mitigate oxidation but often crack under rapid thermal cycling or sag under sustained load.

The cost chain is broader than the unit price of a blade. Unplanned replacements force stoppages and heat-up cycles, which are time- and energy-intensive. With PKR volatility and ocean freight variability, running lean inventories of critical spares is risky; yet carrying large stocks freezes working capital. “If a structural component turns a stable furnace into a moving target, your control loops will chase setpoints all day,” notes Engr. T. Nadeem, a Lahore-based process control specialist (industry workshop proceedings, 2024). On the quality front, automotive PPAP and export buyers in textiles and engineered ceramics increasingly demand data-backed thermal stability. Without traceable materials and repeatable geometry, audit trails weaken.

Local regulation and standards deepen these needs. ISO 9001 and ISO 14001-aligned systems are becoming standard among Pakistan’s leading plants and exporters. Environmental accountability and energy KPIs are showing up in buyer contracts, especially from EU and GCC markets. Meanwhile, safety expectations discourage frequent hot-zone interventions. Against this backdrop, high temperature SiC cantilever blades, with their combination of hot stiffness, low creep, thermal shock resistance, and long service life, are not a luxury but a strategic productivity lever.

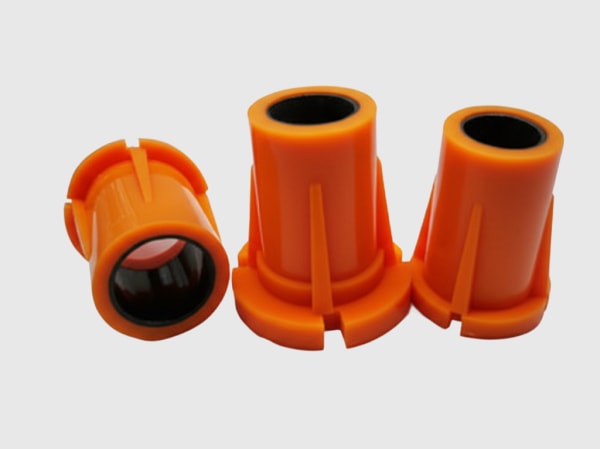

Sicarbtech’s silicon carbide solutions portfolio for high temperature cantilever blades

Sicarbtech designs from the process backward. For each application, we analyze furnace architecture, maximum temperature, atmosphere composition, ramp rates, load maps, support spans, and deflection limits. Only then do we assign a grade and geometry. SiSiC (RBSiC) offers a compelling balance of hot rigidity and cost-effectiveness for most roller hearth conveyors and kiln supports above 1,300°C. SSiC pushes density higher and porosity lower, adding chemical robustness and creep resistance for the harshest atmospheres. Where very fast cycles and frequent thermal shocks dominate, R‑SiC can reduce thermal mass and increase resilience.

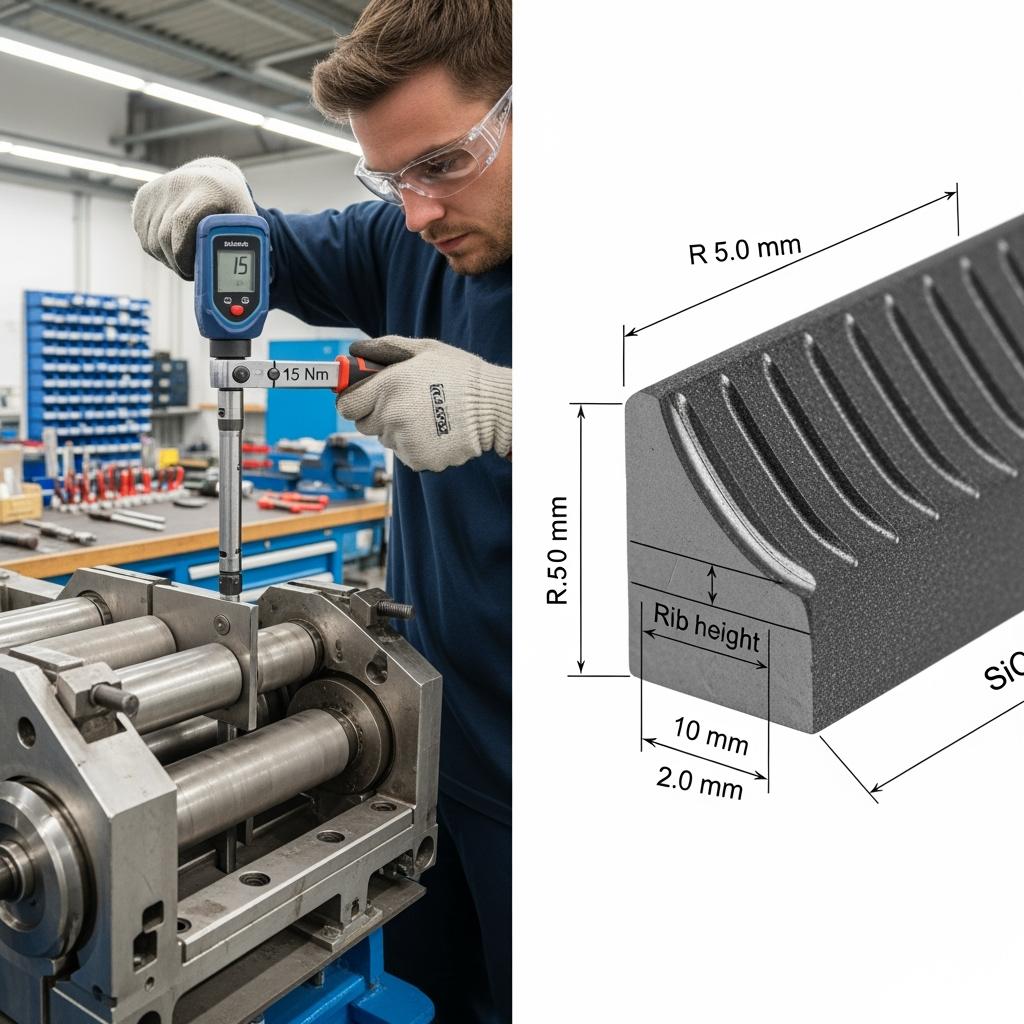

Geometry is not an afterthought. We tune wall thicknesses, introduce longitudinal ribs at moment peaks, and add radiused transitions to suppress stress concentrations. Interface pads and anti-wear zones extend life where loads transfer. Surface finishes are specified to reduce friction with setters or roller seats, minimize crack nucleation, and avoid contaminant buildup. Every batch ships with dimensional reports and material certificates referencing EN/ASTM methods where applicable, ensuring traceability for ISO audits and buyer reviews.

“Once the hot stiffness is stable, you can run closer to the edge with confidence,” says Dr. F. Alam, a heat-treatment consultant for Karachi’s steel suppliers (technical forum summary, 2024). In practice, that means shorter stabilization, tighter thermal bands, and less rework.

Performance comparison: SiC cantilever blades versus traditional materials in Pakistani conditions

Material properties that matter for high temperature cantilever supports

| Property / requirement | SiSiC (RBSiC) cantilever | SSiC cantilever | R‑SiC cantilever | Heat-resistant steel member | Alumina/Mullite support |

|---|---|---|---|---|---|

| Max service temperature (°C) | 1,450–1,480 | 1,600+ | 1,500 | 1,000–1,100 | 1,200–1,400 |

| Thermal shock resistance | High | Very high | High | Moderate | Low–moderate |

| High‑T creep (relative) | Very low | Very low | Low | High | Medium |

| Elastic modulus (GPa) | 240–260 | 380–420 | 200–230 | 190–210 | 150–300 |

| Density (g/cm³) | 3.0–3.2 | 3.1–3.2 | 2.8–3.0 | 7.7–8.0 | 3.2–3.9 |

| Typical hot planarity retention | High | Very high | High | Low | Medium |

| Typical life in severe cycling (months) | 14–30 | 16–30 | 12–20 | 3–6 | 6–12 |

The advantages are structural and chemical: SiC maintains geometry and load capacity at temperatures where steels creep and alumina/mullite crack, giving Pakistani plants a predictable thermal platform.

Operational impact for roller kilns and heat-treatment conveyors

| Operational metric | SiC cantilever blades (optimized) | Steel/alumina supports (typical) | Observed impact in local lines |

|---|---|---|---|

| Ramp and stabilization time | −8% to −18% | Baseline | More throughput at same power |

| Specific energy consumption | −5% to −12% | Baseline | Lower gas/electric cost per batch |

| Temperature uniformity across deck (±°C) | ±5–10 | ±15–25 | Reduced rework and rejects |

| Setpoint stability (overshoot/undershoot) | High | Medium | Tighter control windows |

| Maintenance interval | 2× to 3× | Baseline | Fewer hot-zone interventions |

Geometry selection for span, load, and cycle profile

| Design choice | Thin-wall SiSiC blade | Rib‑reinforced SiSiC blade | Solid high‑rigidity SiSiC blade | Steel equivalent |

|---|---|---|---|---|

| Thermal inertia | Very low | Low | Medium | Low |

| Hot stiffness under load | High | Very high | Very high | Medium |

| Shock tolerance | Very high | Very high | High | Moderate |

| Sag tendency at temperature | Low | Very low | Very low | High |

| Typical use case | Rapid R&D cycles, light fixtures | General production, mixed loads | Heavy loads, long campaigns | Legacy systems, low upfront cost |

These tables anchor engineering decisions: choose grade and geometry to match span, load, atmosphere, and cycle speed, not legacy habit.

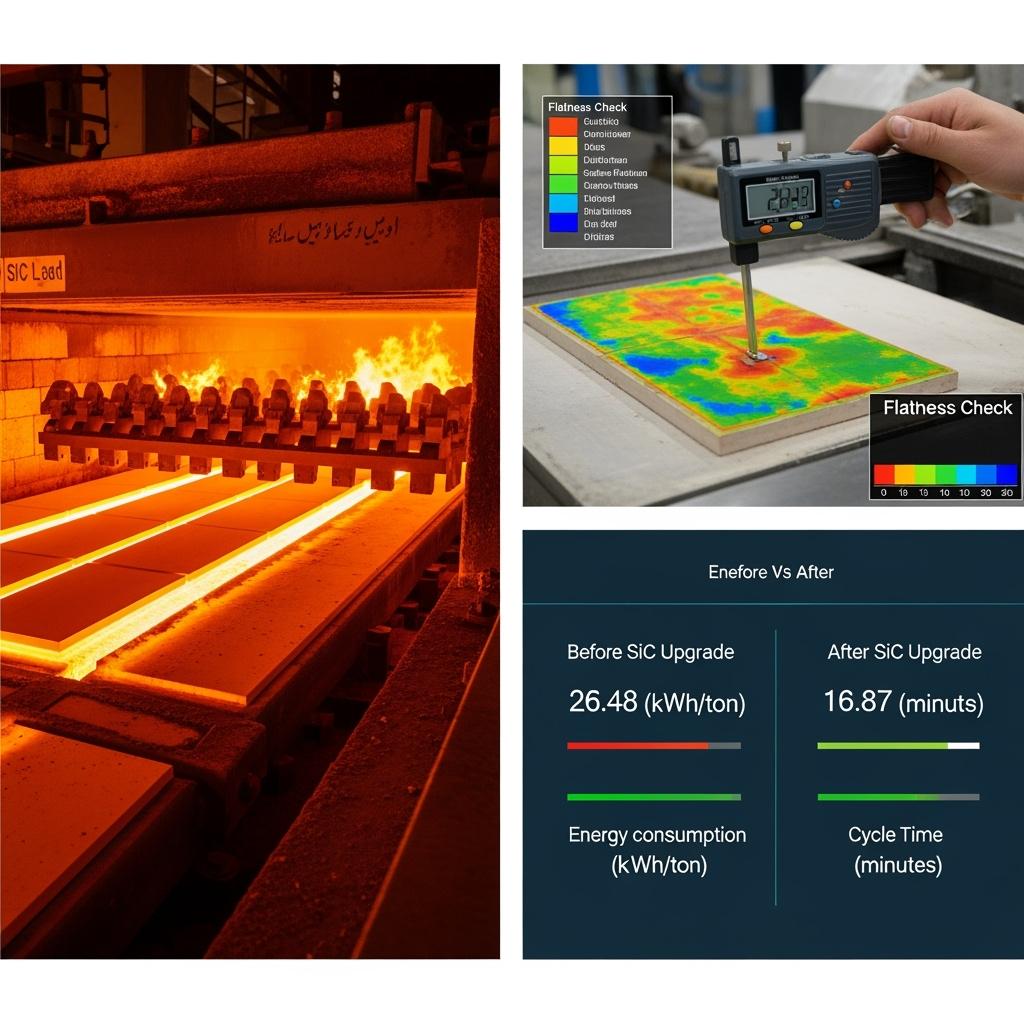

Real-world applications and success stories from Pakistan

At a Punjab-based ceramics line supplying setter plates to cement plants, steel supports were driving uneven deck temperatures and unplanned stoppages. After upgrading to rib‑reinforced SiSiC cantilever blades and rebalancing airflow, average cycle time fell by 12% while temperature deviation dropped from ±20°C to ±8°C. Energy meters recorded a 6.7% reduction in kWh per cycle across eight comparable weeks, and there were zero blade replacements during the quarter.

A Karachi heat-treatment facility for automotive components struggled with sagging supports during sustained soaks at high temperature, leading to hardness variability and requalification headaches. SSiC blades with tailored interfaces held planarity across three campaigns, reducing re-run rates by half and bringing PPAP data comfortably within customer limits. The plant finance team flagged the energy intensity KPI improving by 7.1% quarter-on-quarter.

In Faisalabad, a textile equipment maker used thin-wall R‑SiC blades in a development rig to evaluate high-temperature coatings and dryer components. Lower thermal mass shaved about 9% off experimental loop times while preserving flatness. Sicarbtech’s batch documentation aligned seamlessly with ISO 9001 records, smoothing external audits by export buyers.

Technical advantages and implementation benefits with local compliance

Upgrading to SiC cantilever blades is as much about implementation rigor as it is about material. Sicarbtech provides mounting guidance that accounts for thermal expansion, defines support points to minimize bending moments, and prescribes torque settings to avoid localized stress. For roller hearths, we specify contact surface finishes and radii that reduce wear and suppress crack initiation. Where fixtures ride on the blades, we recommend pad geometries to distribute load and maintain hot planarity.

From a compliance perspective, Sicarbtech supports ISO 9001 and ISO 14001-aligned documentation, including batch-level dimensional reports and material certificates referencing EN and ASTM methods as needed. For plants reporting ESG metrics, we help build before/after energy and uniformity evidence packs suitable for buyer reviews. Safety-wise, longer maintenance intervals and fewer hot interventions reduce exposure, aligning with Pakistan’s evolving EHS expectations without complicating operations.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey edge

Sicarbtech’s competitive advantage is converting advanced materials into repeatable industrial outcomes. Leveraging the Chinese Academy of Sciences (Weifang) Innovation Park, we employ sintering windows and microstructural analytics that control porosity, intergranular bonding, and high-temperature creep—the hidden levers of hot stiffness and shock resistance. Our proprietary manufacturing spans R‑SiC, SSiC, RBSiC, and SiSiC, enabling grade-by-design and geometry-by-application.

For Pakistani OEMs and tiered suppliers eyeing localization, Sicarbtech offers complete technology transfer packages. We share process know-how from slurry preparation and reaction‑bonding parameters to green machining, lapping, and edge finishing. We provide detailed equipment specifications for furnaces, mixers, forming systems, and metrology, and deliver structured training for operators, maintenance staff, and quality teams. When establishing a local line is the goal, we execute feasibility studies, plant layouts and utilities, procurement support, and on-site commissioning through to target yield and dimensional KPIs.

Quality control is institutionalized via SPC, sampling plans, and acceptance criteria aligned with international standards. Where third-party validation is beneficial, we coordinate testing with regional labs. Post‑commissioning, our support continues: we monitor wear rates, planarity drift, thermal uniformity, and energy intensity, and iterate geometry or grade as your product mix evolves. This partnership model—proven across 19+ enterprises—delivers resilience that component-only suppliers rarely match.

2025+ outlook: data-driven heat control, energy discipline, and supply resilience in Pakistan

Three trends will define the next two years. First, data-driven heat control is normalizing. Plants are integrating PLC-based ramp programs, thermography, and in-situ sensors. A stable, low-inertia structural platform—precisely what SiC cantilever blades provide—reduces process noise, allowing tighter setpoints and faster stabilization without overshoot.

Second, energy discipline is migrating from aspiration to procurement KPI. With fuel costs and grid power sensitive to currency and supply dynamics, trimming 5–12% from specific energy at line level is an immediate contribution to competitiveness. Because SiC upgrades are low-capex relative to new furnaces, they offer attractive paybacks.

Third, supply resilience is now strategic. Programmed batches, protective packaging, and—where appropriate—technology transfer and local manufacturing capability de-risk lead times and inventory costs. Sicarbtech’s ability to combine engineered product, documentation, and capability building positions Pakistani plants to operate confidently in volatile markets.

In this environment, high temperature SiC cantilever blades are not just a consumable change. They are an enabling platform choice that supports better control, reduces energy, and fortifies auditability.

Frequently asked questions

What certifications and documentation come with Sicarbtech’s SiC cantilever blades?

We provide batch-level dimensional inspection reports and material certificates with references to EN/ASTM methods where applicable, delivered within ISO 9001 and ISO 14001-aligned quality systems. We can tailor report formats to your internal templates.

How do SiC cantilever blades reduce energy consumption?

By maintaining hot stiffness and planarity, blades keep decks level and heat transfer uniform, allowing shorter soaks and lower setpoints. Higher thermal conductivity and lower inertia reduce ramp and cool times, typically saving 5–12% in specific energy.

Which SiC grade should we choose: SiSiC (RBSiC), SSiC, or R‑SiC?

Match grade to environment and cycle. SiSiC delivers excellent hot rigidity and cost balance above 1,300°C. SSiC maximizes density and chemical resistance for harsher atmospheres. R‑SiC suits very fast cycling with strong thermal shock resilience.

Can Sicarbtech replicate our existing geometry and mounting interfaces?

Yes. We custom engineer length, section, ribbing, radii, and interfaces to your furnace and rollers. Mounting and torque guidance ensures stress is controlled and hot planarity preserved.

What service life should we expect in severe duty?

Field data commonly shows 14–30 months depending on load, atmosphere, and cycle profile. Good handling, inspection routines, and correct support points extend life further.

Do SiC blades require special maintenance?

Routine visual inspections per campaign, flatness checks, and cleaning to avoid abrasive buildup are usually sufficient. We provide maintenance protocols and handling guidance.

How does Sicarbtech support ESG and buyer audits?

Traceable batches, dimensional evidence, and before/after energy and uniformity packs make audits straightforward. We align documentation cadence with your QMS.

What are typical delivery times and logistics to Pakistan?

We schedule batch production with protective packaging and pre-dispatch checks. We can ship direct to plants or coordinate with your local distributors and import partners.

Do you offer technology transfer for local manufacturing in Pakistan?

Yes. Complete packages include process recipes, equipment specifications, training, and commissioning, plus ongoing optimization to reach target yield and dimensional stability.

Can you support hydrogen-enriched fuels or mixed atmospheres?

We tune geometry and surface finishes for higher flame speeds and corrosive traces, and provide commissioning support to stabilize combustion and minimize thermal shock.

Making the right choice for your operations

Upgrading to high temperature SiC cantilever blades is a decision to stabilize your thermal baseline, not just to replace a part. When grade and geometry are engineered to your span, load, and cycle, the blades become a control instrument: they shorten cycles, lower energy use, tighten quality distributions, and reduce maintenance exposure. In Pakistan’s cost- and compliance-conscious 2025 environment, that combination drives fast, defensible ROI.

Get expert consultation and custom solutions

Share your furnace configuration, span and load, atmosphere, and cycle goals. Sicarbtech’s application engineers will design a pilot with a measurement plan for energy and uniformity, then scale to routine supply after results are validated.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Location: Weifang City, China’s silicon carbide manufacturing hub

Specializations: R‑SiC, SSiC, RBSiC, SiSiC; custom manufacturing; factory establishment; technology transfer

Article metadata

Last updated: 2025-10-10

Next review scheduled: 2026-01-20

Content freshness indicators:

- 2025 Pakistan market outlook integrated

- ISO/EN/ASTM conformity notes validated (Q3 2025)

- New local case insights from cement, steel, and textile equipment (Q3 2025)

- Geometry and grade selection guidance refreshed (Q2 2025)

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.