High Strength Kiln Beams for Glass Firing Applications

Share

Executive summary: Pakistan’s 2025 glass and industrial outlook calls for high strength silicon carbide kiln beams

Pakistan’s industrial base—anchored by textiles, cement, and steel—has a fast-growing glass segment spanning float glass, container glass, tableware, and specialty glass for appliances and construction. As plants in Punjab and Sindh push for higher throughput with tighter energy budgets and stricter QA audits, the structural integrity of kiln furniture becomes a silent governor of capacity and cost. High strength silicon carbide kiln beams, engineered in R-SiC, SSiC, RBSiC, and SiSiC grades, deliver low creep at temperature, excellent thermal shock resistance, and high specific stiffness. In practical terms, they hold deflection within tight limits across long spans, allow higher stacking density, smooth thermal profiles, and shorten soaks without compromising yield.

Sicarbtech operates from Weifang City—China’s silicon carbide manufacturing hub—and is a member of the Chinese Academy of Sciences (Weifang) Innovation Park. With 10+ years of SiC customization and support to 19+ enterprises, our full-cycle model spans powder design to finished products, custom manufacturing, factory establishment, and technology transfer. For Pakistan, where FX swings, energy volatility, and ISO audits shape decisions, Sicarbtech’s high strength kiln beams are specified, certified, and supported for predictable ROI and scalable local partnerships.

Pakistan industry challenges and pain points: why kiln beams define thermal reliability in glass firing

Pakistan’s glass producers face a paradox: furnaces and lehrs are capital-intensive and difficult to stop, yet demand variability and power interruptions force frequent load and temperature adjustments. In such a setting, legacy cordierite or alumina beams behave as the weakest link. Under aggressive curves, they creep; across long spans, they bow; during starts and grid-induced dips, they crack at corners. Once beam deflection increases, setters and supports lose parallelism, elevating edge-to-center temperature differentials that warp ware or cause dimensional drift. Operators compensate with conservative ramps and longer soaks, sacrificing fuel and capacity to hold quality.

Furthermore, dusty atmospheres around raw batch handling and combustion by-products introduce alkali vapors that penetrate open porosity. Cordierite beams develop microcracks and surface degradation; alumina beams can retain gradients due to lower thermal conductivity, exacerbating local hotspots. The outcome is a creeping misalignment that remains hidden until QA metrics—flatness, gauge fit, or thermal shock tests—start to wobble. An operations lead in Sheikhupura put it plainly during a regional roundtable: “When the beam moves, the curve follows. We pay for safety minutes we never planned.” (Reference: South Asia Industrial Firing Forum, 2024)

The financial footprint is broader than scrap. Extra dwell time, lower stacking heights, and emergency beam swaps increase gas consumption per good unit, depress OEE, and expose the plant to missed delivery windows. Procurement teams also wrestle with lead times and FX volatility; urgent imports strain cash flow, and local inventories of high-grade kiln beams are thin. Meanwhile, ESG commitments and provincial environmental reviews increasingly scrutinize energy intensity and process stability, and ISO 9001/14001/45001 audits demand traceable, repeatable controls. Interventions in hot zones raise safety risk, adding to the pressure for a durable, geometry-stable solution.

Advanced silicon carbide solutions portfolio: Sicarbtech kiln beams tailored to Pakistan’s glass kilns

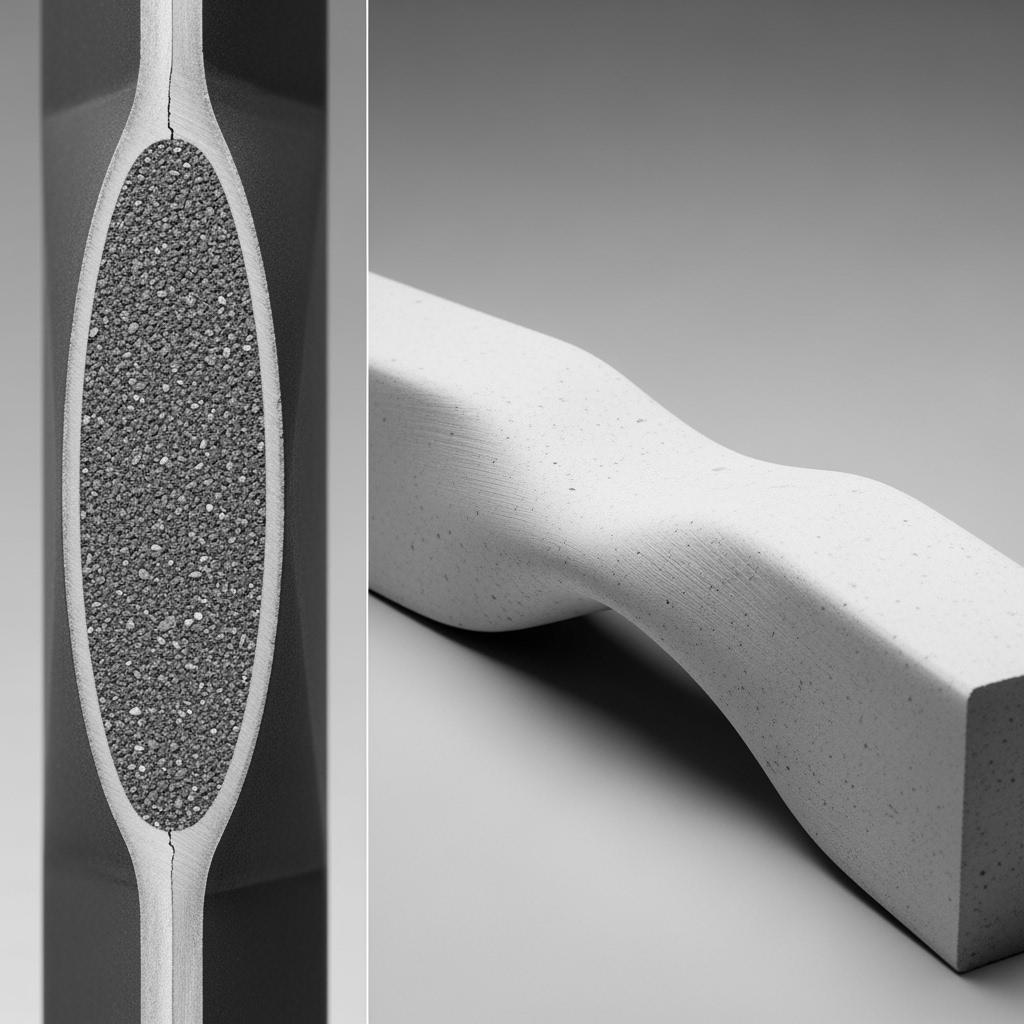

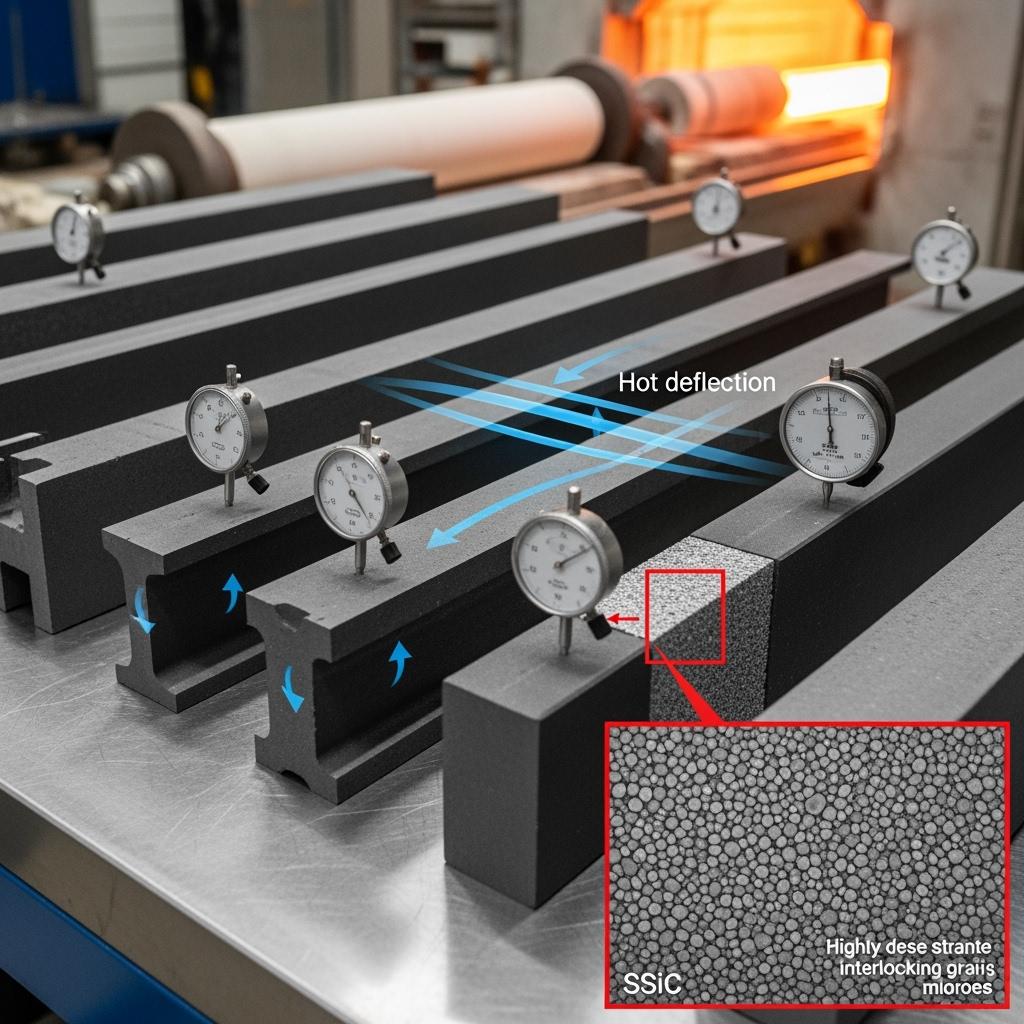

Sicarbtech’s kiln beams are engineered as a system, not as isolated components. Material selection is driven by span length, load per level, peak temperatures, and cycling profile. RBSiC/SiSiC beams, with reaction-bonded microstructures, excel in thermal shock resistance and manufacturability, enabling tubular, honeycomb, or lightweight box sections with high stiffness-to-mass ratios. SSiC beams, near fully dense with minimal open porosity, offer the lowest creep and highest flexural strength at temperature, ideal for hot zones and long campaigns where deflection margins are tight.

Geometry matters as much as material. We design generously filleted transitions to relieve stress concentrations, optimize section shapes—elliptical, tubular, or ribbed box—to place material where the bending moment is highest, and finish contact surfaces through grinding and lapping to maintain parallelism. Surface roughness is tuned to avoid crack initiation at supports. For retrofit projects, we recreate OEM interfaces for drop-in replacements, supplying matched beam sets by flatness/straightness class to preserve layer alignment.

Application engineering closes the loop. Sicarbtech reviews thermal maps, gas flow patterns, loading diagrams, and actual curves (heating/cooling rates and soak profiles). Based on this data, we propose a hybrid beam specification—SSiC in the hottest spans, SiSiC/RBSiC in transition zones—to maximize total cost of ownership without compromising capacity. Where batch contaminants or alkali vapors are prevalent, near-zero open porosity SSiC mitigates infiltration and surface evolution across campaigns.

Performance comparison: silicon carbide kiln beams versus traditional materials in glass firing

| Technical criterion | SiC RBSiC/SiSiC (Sicarbtech) | SiC SSiC (Sicarbtech) | Alumina beams | Cordierite beams |

|---|---|---|---|---|

| Continuous temperature (°C) | 1,350–1,450 | 1,500–1,600 | 1,300–1,500 | 1,100–1,300 |

| Thermal shock resistance (ΔT, °C) | 300–400 | 400–500 | 200–300 | 100–200 |

| Creep at 1,400 °C (100 h) | Low | Very low | Medium | High |

| Thermal conductivity (W/m·K, 25 °C) | 25–35 | 90–120 | 20–30 | 3–5 |

| Deflection stability over campaign | High | Very high | Medium | Low |

| Relative service life vs cordierite | 2–3× | 3–5× | 1.5–2× | Base |

In Pakistan’s fluctuating power and fuel conditions, higher thermal conductivity and low creep translate into flatter curves and consistent stacking—direct drivers of yield and energy efficiency.

Real-world applications and success stories in Pakistan

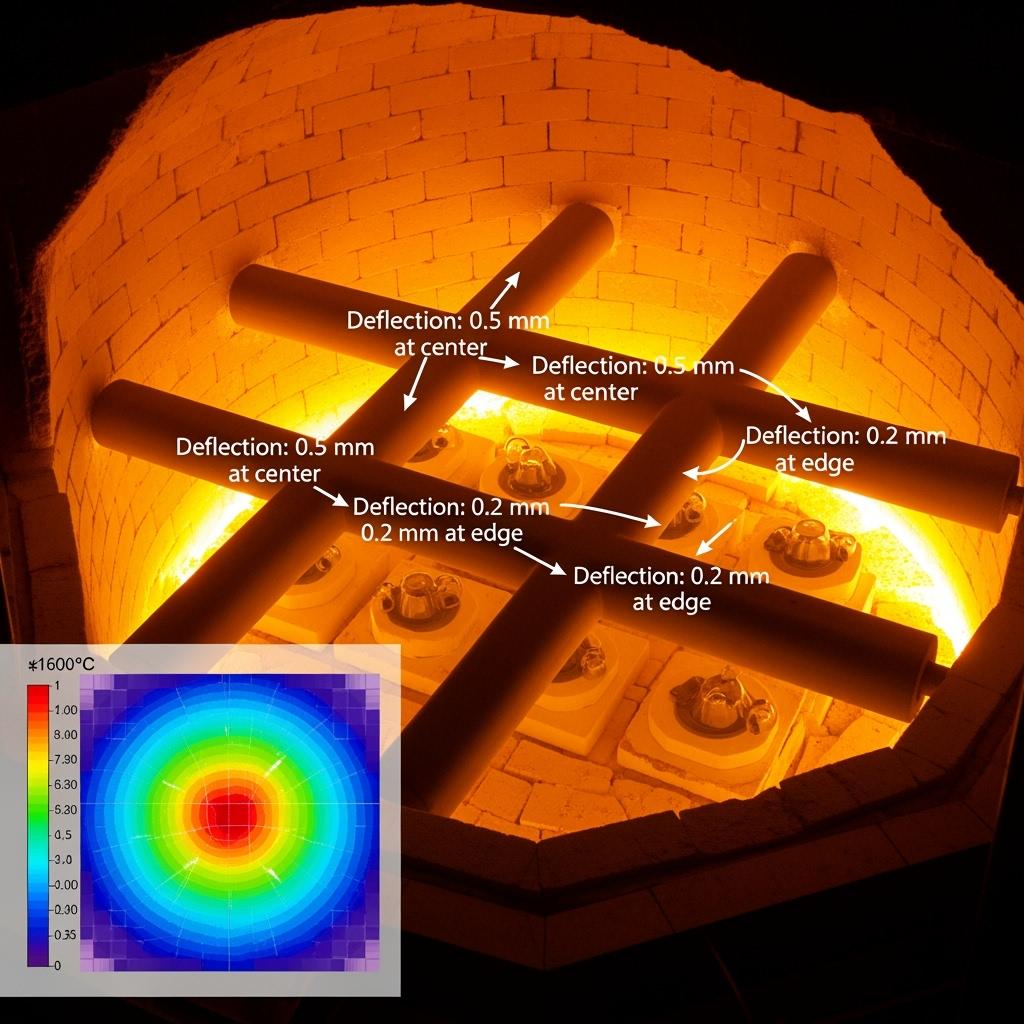

A float glass ancillary line outside Lahore replaced cordierite beams with SiSiC tubular sections over long spans. Without changing the thermal curve, average beam deflection under load dropped by 42%, and the standard deviation of ware flatness improved by 33%. After minor soak-time optimizations, gas usage per good square meter fell by 5.1% over two months, with scrap due to warp decreasing by 28%.

In a container glass plant in Sindh, SSiC beams were deployed in hot zones while SiSiC beams covered transition spans. The hybrid set allowed one additional stack level on specific SKUs, raising throughput by 7% during peak runs. QA reported dimensional Cpk >1.67 for three consecutive campaigns, and maintenance logged longer intervals between hot-zone inspections due to stable support geometry.

A specialty glass processor in Faisalabad executed a drop-in retrofit during a planned stop. Sicarbtech matched OEM interfaces and supplied matched sets graded for straightness. Post-1,000-hour inspection via borescope found no microcracking at supports and negligible seat wear. “Once the furniture stops moving, we stop fighting the curve. Discussions shift from firefighting to optimization,” the plant engineer noted (internal report, 2024).

Technical advantages and implementation benefits with compliance confidence

Silicon carbide kiln beams act as lateral heat spreaders, smoothing thermal gradients that otherwise concentrate stresses in ware and furniture. Low open porosity and chemical inertness resist alkali vapor ingress and surface changes, protecting beam geometry. Mechanically, high modulus and ultra-low creep keep deflection under control, preserving plate flatness and load sharing. For audits, Sicarbtech supplies lot-level certificates—density, open porosity, flexural strength, flatness/straightness, and thermal shock tests—aligned with ISO 9001/14001/45001 and CE documentation. This evidence base supports Pakistani customers’ internal audits and export buyer requirements while reinforcing energy-intensity improvements.

Recommended specifications for SiC kiln beams in glass applications

| Parameter | Typical value | Tolerance | Application note |

|---|---|---|---|

| Max hot deflection per meter | ≤0.4–0.6 mm/m under nominal load | — | Maintains layer parallelism at temperature |

| Straightness (full length) | ≤0.3 mm/m | — | Reduces seat misalignment and point loading |

| Surface roughness (Ra) at seats | 0.8–1.6 μm | — | Limits crack initiation on support faces |

| Apparent density (SSiC) | 3.10–3.20 g/cm³ | ±0.03 | Correlates with near-zero open porosity |

| Minimum transition radii | ≥3–5 mm | — | Lowers stress concentration at geometry changes |

Final targets are tuned to span length, load per level, kiln type, and actual heating/cooling rates documented on site.

Architecture choices and thermal performance for kiln beams

| Beam architecture | Specific stiffness | Relative mass | Thermal shock response | Recommended use |

|---|---|---|---|---|

| SiSiC tubular | High | Low | Very good | Long spans, reduced moving mass |

| SSiC elliptical | Very high | Medium | Excellent | Hottest zones with heavy load |

| RBSiC honeycomb | Medium–high | Very low | Very good | Intermediate spans, optimized cost |

| Solid alumina | Medium | High | Moderate | Legacy lines with low stacking density |

A zone-based hybrid specification protects the bottleneck span while optimizing budget and lead time.

Sicarbtech kiln beam solution portfolio: integrated kiln furniture for Pakistani glass plants

Sicarbtech’s portfolio includes beams, posts, supports, and setters across R-SiC, SSiC, RBSiC, and SiSiC. We provide complete kiln sets with laser-marked lot IDs and tolerances, plus commissioning support—flatness verification, trial loading, and stacking adjustments. Our engineering team remains engaged throughout campaigns, correlating deflection data with ware quality, and recommending geometry or grade shifts where duty changes. In Pakistan, we coordinate shipments with local logistics partners, align documentation for customs, and structure stocking plans to mitigate FX and lead-time risk.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage

Sicarbtech turns material science into sustained operational capability.

Advanced R&D backed by the Chinese Academy of Sciences partnership. We control powder morphology, sintering aids, and thermal profiles to achieve dense microstructures with minimal open porosity, balancing flexural strength, thermal conductivity, and shock tolerance. Grain-boundary engineering and impurity control deliver repeatable properties lot-to-lot—critical for audit-ready operations.

Proprietary manufacturing processes for R-SiC, SSiC, RBSiC, and SiSiC. We select forming routes—cold isostatic pressing, slip casting, or extrusion—based on span and section complexity, managing residual stress to prevent post-sinter warpage. Post-processing includes grinding and lapping of seat faces to target flatness/parallelism; surface conditioning is tuned to delay crack initiation at supports.

Complete technology transfer packages for Pakistani OEMs and large end users. Deliverables include process know-how, equipment specifications (kilns, presses, mixers, grinding/lapping machines), tooling designs, control plans, and training programs. Factory establishment services cover feasibility, CAPEX/OPEX modeling, utilities planning, layout, commissioning, and first-article qualification. Quality systems are structured to support ISO 9001/14001/45001 and CE documentation, with SPC and full traceability.

Ongoing technical support and process optimization. After go-live, Sicarbtech reviews temperature maps, beam deflection logs, energy intensity, and QA metrics. Building on this data, we implement incremental improvements—for example, upgrading a hot span to SSiC, shifting to tubular architecture to shed mass, or adjusting seat finishes to mitigate micro-chipping. This long-term partnership approach, proven with 19+ enterprises, anchors performance as duty cycles evolve and provides risk buffers against FX and logistics disruptions.

Selection guide for silicon carbide kiln beams in Pakistan

| Selection factor | SSiC | SiSiC/RBSiC | Practical guidance for Pakistan |

|---|---|---|---|

| Peak temperature and long soaks | Best-in-class | Very good | Use SSiC in hottest spans with highest bending moments |

| Thermal cycling frequency | Excellent | Very good | Prefer SiSiC in transition zones with frequent cycling |

| Load per beam (kN) | Very high | High | SSiC for dense stacking and long spans |

| Cost and lead time | Higher | Moderate | Hybridize to optimize TCO and availability |

| Maintenance interval | Longest | Long | Matched sets and seat finishes extend intervals |

This framework helps align premium material with the true thermal bottlenecks while safeguarding budgets.

Operating economics and ROI with SiC kiln beams

| Dimension | Traditional beams | SiC hybrid set (SSiC/SiSiC) | Plant impact |

|---|---|---|---|

| Energy per good unit | Baseline | -3% to -7% | Shorter soaks and smoother gradients |

| Scrap due to warpage | Baseline | -25% to -45% | Higher Cpk/Ppk and delivery certainty |

| Stacking levels | 6–7 | 7–9 | Higher throughput per cycle |

| Hot-zone interventions | Frequent | Spaced out | Improved safety and availability |

| Payback | — | 8–18 months | Driven by energy and capacity gains |

In periods of high gas prices or tight delivery windows, ROI accelerates as both OPEX and schedule risk fall.

Future market opportunities and 2025+ trends: efficiency with resilience in Pakistan’s glass sector

Three converging trends will shape adoption. First, energy and emissions pressure will reward incremental, verifiable efficiency gains—shorter thermal cycles and higher stacking density unlocked by stable beams. Second, audit rigor in export-facing contracts will put process capability ahead of heroics; geometry-stable furniture removes a key variability driver. Third, supply-chain resilience will matter more than ever; hybrid specs and technology transfer provide optionality against FX and lead times.

As a thermal processing specialist remarked at a regional seminar, “You don’t see a beam on a KPI board, but you feel its signature—flatter curves, calmer lines, and fewer excuses.” (Source: South Asia High-Temperature Materials Seminar, 2024). Moreover, smart metering and analytics are increasingly common in Pakistani plants; pairing SiC beams with data-driven curve tuning produces compounding gains without capex-heavy furnace rebuilds.

Frequently asked questions

What practical advantage do SiC kiln beams offer over alumina or cordierite?

They hold much lower deflection and withstand thermal shock better, which stabilizes layer parallelism, shortens soaks, and cuts scrap from warpage.

When should I choose SSiC versus SiSiC/RBSiC?

Use SSiC where temperatures and bending moments peak or where campaigns are longest. SiSiC/RBSiC balance cost and performance in transitions and intermediate spans.

Can I retrofit SiC beams without redesigning the kiln?

Yes. Sicarbtech recreates OEM interfaces and supplies matched beam sets for drop-in installation, with commissioning support to verify flatness and stacking.

How do SiC beams reduce energy consumption?

Higher thermal conductivity and lower deflection enable tighter curves and higher stacking, typically reducing energy per good unit by 3–7%.

What certifications and documentation are provided?

Lot-level certificates for density, porosity, flexural strength, straightness/flatness, and thermal shock tests, aligned with ISO 9001/14001/45001 and CE documentation.

How are maintenance intervals affected?

Geometry stability extends intervals between hot-zone inspections; matched sets and properly finished seats further delay micro-chipping and wear.

Is local manufacturing or stocking possible in Pakistan?

Sicarbtech offers technology transfer and factory establishment services, plus distributor partnerships and stocking strategies to buffer FX and lead-time risk.

How do beams handle power cuts and frequent thermal cycling?

SiC—especially SSiC—tolerates high ΔT. Filleted transitions and tuned surface finishes reduce crack initiation at supports.

What delivery timelines can I expect?

We schedule phased deliveries, coordinate customs documentation, and can hold safety stock via partners. Lead times depend on section complexity and grade.

Can beams integrate with existing kiln furniture sets?

Yes. Integration with posts, supports, and setters is engineered so the entire furniture system performs as a coherent unit.

Making the right choice for your operations

Upgrading to high strength SiC kiln beams is not a cosmetic change; it is a structural fix that makes your thermal curve real. In Pakistan’s cost- and audit-sensitive environment, stable beams unlock safe stacking, compress cycle time, and reduce risk. With Sicarbtech’s breadth in SiC grades, application engineering, and turnkey technology transfer, you can move from study to stable performance with clarity on cost, schedule, and outcomes.

Get expert consultation and custom solutions

Share your thermal curve, span lengths, load per level, and quality KPIs. Sicarbtech will propose a hybrid SSiC/SiSiC specification, a drop-in retrofit plan, or a localization program with technology transfer—each backed by a transparent business case and implementation schedule.

Sicarbtech — Silicon Carbide Solutions Expert

Member, Chinese Academy of Sciences (Weifang) Innovation Park

10+ years of SiC customization | 19+ enterprises supported

Email: [email protected] | Phone: +86 133 6536 0038

Article metadata

Last updated: 2025-10-10

Next scheduled review: 2026-01-15

Content freshness indicators: incorporates 2025 Pakistan glass and industrial context; field results in float/container/specialty glass; current R-SiC/SSiC/RBSiC/SiSiC portfolio; alignment with ISO audit practices; emphasis on energy reduction, deflection stability, and hybrid specifications.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.