Corrosion-Resistant Paddles for Industrial Fluid Handling

Share

Executive Insight: 2025 Outlook for Corrosion-Resistant Paddle Mixers in Pakistan

Pakistan’s industrial base—anchored by textiles, cement, and steel—enters 2025 facing intensified pressure to boost uptime, reduce total cost of ownership, and comply with tightening environmental and safety standards. In corrosive fluid handling, the hidden cost of impeller and paddle failures—unplanned shutdowns, contamination risks, and high replacement frequency—continues to erode margins. Meanwhile, water treatment upgrades, chemical intermediates expansion in Punjab and Sindh, and selective modernization in the fertilizer and dye sectors are accelerating demand for chemically resistant mixing components that can endure harsh media without performance drift.

Sicarbtech, the Silicon Carbide Solutions Expert headquartered in Weifang City—China’s silicon carbide manufacturing hub—brings over a decade of silicon carbide engineering to Pakistan’s emerging needs. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech delivers full-cycle solutions from material processing to finished R-SiC, SSiC, RBSiC, and SiSiC components, backed by custom manufacturing, factory establishment, and technology transfer services. For local operators seeking corrosion-resistant paddles and impellers that survive acid, alkali, brine, and abrasive slurries, advanced silicon carbide (SiC) is no longer aspirational—it is a pragmatic, budget-protecting path to reliability.

Furthermore, with PKR volatility, energy constraints, and stricter NEQS discharge requirements shaping procurement choices, stakeholders are moving from lowest-capex buying to lifecycle value models. In that shift, SiC paddles offer a compelling ROI: higher wear resistance, stable hydrodynamics over longer service intervals, and compatibility with PTFE-lined housings and ceramic shaft sleeves. This pillar page distills hard-won lessons from 19+ enterprise engagements, localizes them to Pakistan’s conditions, and outlines how to adopt SiC paddle solutions with confidence in 2025 and beyond.

Industry Challenges and Pain Points in Pakistan’s Corrosive Fluid Handling

In textile dyeing and finishing, corrosive dyes and oxidizing agents attack metal paddles, causing pitting, roughness growth, and turbulence spikes that degrade mixing quality and create color inconsistencies. Cement and steel sectors—especially in pickling lines and recirculation of acidic scrubber liquors—experience impeller erosion that compounds energy draw as surfaces roughen. Municipal and industrial water treatment plants face scaling and corrosion in chlorination and coagulation stages, where iron-based paddles corrode, shedding particulates and increasing maintenance frequency. Moreover, shutdown windows across Lahore, Karachi, and Faisalabad plants are squeezed by production targets, leaving little tolerance for frequent impeller replacements.

“Unplanned corrosion-related failures cost more than parts; they steal throughput and erode compliance margins,” notes a senior process engineer at a leading Lahore textile mill. “We budget replacements every 6–9 months, but reality often compresses that to 4–5 months when acidity fluctuates.” This variability is costly in PKR terms: each emergency replacement involves logistics delays, exchange rate exposure for imported parts, and safety risks during hot swaps.

In addition, local regulatory pressures are rising. The Pakistan Environmental Protection Agency’s enforcement of NEQS standards for effluent quality, combined with provincial environmental tribunals’ oversight, is pushing operators to ensure robust, leak-free mixing in neutralization and oxidation processes. Inferior paddles that corrode can introduce metals into discharge streams, complicating compliance and risking penalties. Furthermore, ISO 9001-driven quality systems adopted by export-focused textile producers demand traceability and stable mixing performance to maintain dye lot consistency.

Operationally, standard stainless steel grades like 304/316, and even duplex alloys, show accelerated degradation in chloride-rich or low-pH slurries common in pickling, dye baths, and certain fertilizer intermediates. PTFE-coated steel extends life but struggles with mechanical wear, delamination at edges, and temperature-cycle fatigue. FRP impellers offer corrosion resistance but can crack under particle impact or when exposed to thermal shocks during CIP cycles. The result is a tug-of-war between corrosion resistance and mechanical durability, too often resolved by frequent replacements rather than material innovation.

Cost implications compound over time. The initial capex gap between a traditional paddle and a SiC paddle may be notable in PKR terms, yet lifecycle accounting tells a different story: fewer shutdowns, reduced spare inventory, and energy savings from consistent surface finish and geometry. As energy tariffs fluctuate and grid instability forces generator usage, maintaining mixing efficiency becomes a direct cost lever. Additionally, procurement teams face currency volatility on import components; longer-lived paddles become a hedge against FX risk.

Finally, market conditions include fragmented local supply chains for advanced ceramics, limited domestic manufacturing depth for technical SiC components, and a skills gap in installation and alignment for ceramic paddles. These challenges call for a partner capable not only of supplying components but of transferring know-how, validating designs in local media, and training maintenance teams for handling and installation—precisely where Sicarbtech’s turnkey approach reduces adoption risk.

“Materials selection is now a strategic decision,” observes Dr. Farid Ahmad, materials engineering consultant and visiting lecturer in Lahore (industry commentary, 2024). “With environmental compliance and energy efficiency converging, the industry cannot afford trial-and-error. Evidence-based SiC applications have shifted the economics.” His assessment mirrors our experience: when SiC paddles are engineered with correct thickness, edge geometry, and hub design—plus compatible shaft and bearing materials—plants see a step change in uptime and cost predictability.

Advanced Silicon Carbide Solutions Portfolio for Corrosive Paddles and Impellers

Sicarbtech’s portfolio is engineered to address the precise pain points described above. Rather than generic “ceramic” components, we deliver grade-specific SiC paddles tuned to chemistry, temperature, solids loading, and hydrodynamic shear requirements.

At the core are four material families:

- R-SiC (Reaction-bonded silicon carbide) for high toughness and complex shapes where near-net molding improves cost-efficiency.

- SSiC (Sintered silicon carbide) for maximum chemical resistance and high-temperature stability, ideal for aggressive acids and hot alkaline liquors.

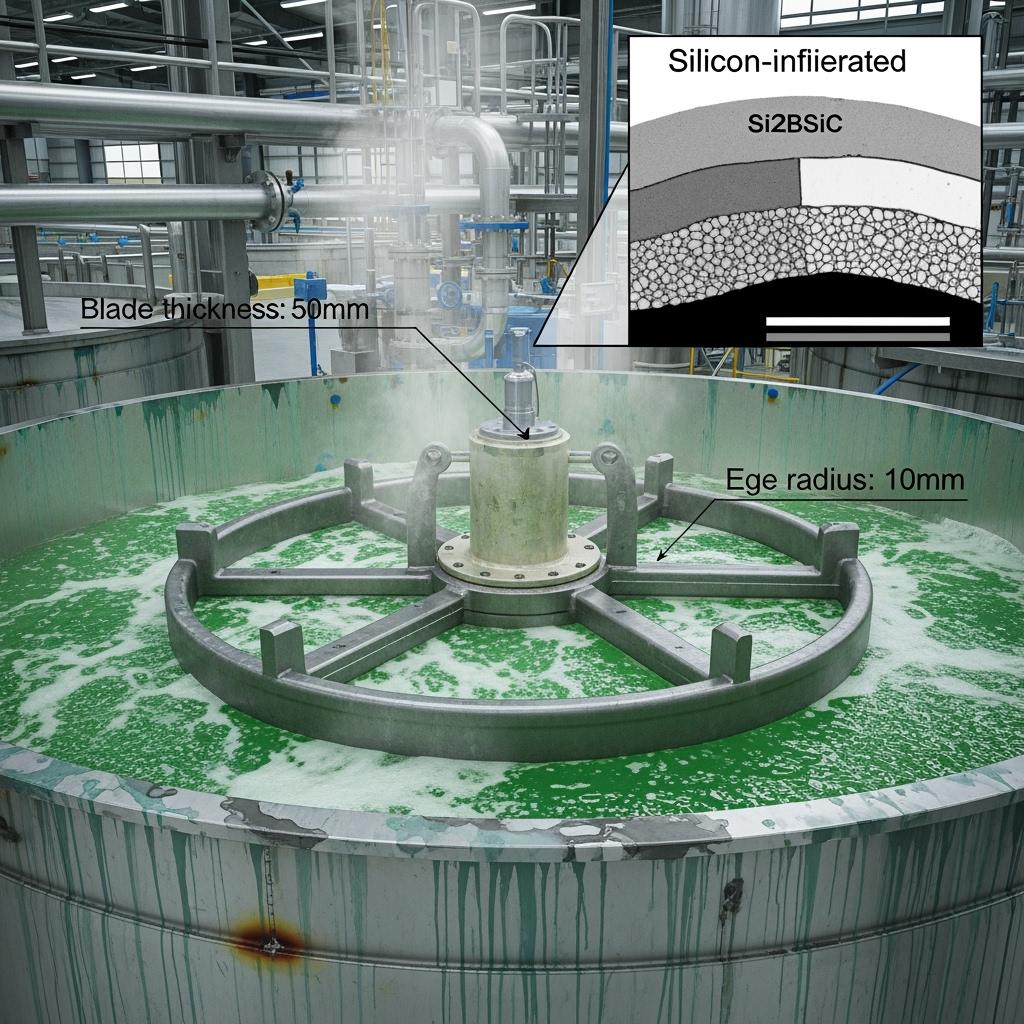

- RBSiC/SiSiC (Reaction-bonded with silicon infiltration) balancing manufacturability, strength, and precision for larger-diameter paddles and impellers.

Additionally, we integrate hybrid designs such as SiC blades with PTFE or PFA-lined hubs, and SiC paddles paired with ceramic-coated shafts to mitigate galvanic issues. Building on this, our application engineering team benchmarks your media (pH, chloride content, oxidizer levels), temperature cycles, and slurry abrasivity, then selects the optimal grade and thickness with stress simulations to prevent edge chipping and hub stress concentrations.

For textile dyeing, we commonly supply SSiC paddles with polished surfaces (Ra ≤ 0.2 μm) to reduce fouling and maintain laminar characteristics around the blade. In pickling lines, RBSiC offers an attractive balance: robust against thermal shocks during line changes, yet cost-effective for larger diameters up to 1,800 mm. In water treatment, R-SiC with protective edge geometry extends life in grit-laden clarifiers while ensuring compatibility with standard Pakistani drive couplings.

Sicarbtech’s advantage is not just material science—it is the complete lifecycle service: from design to installation guidance, from pilot validation to scale deployment, and from training to long-term reliability programs. With 10+ years of customization and 19+ enterprise partnerships, we bring proven templates for Pakistan’s operating conditions, reducing trial cycles and accelerating ROI.

Performance Comparison of Silicon Carbide vs Traditional Paddle Materials

Material Performance and Compliance Benchmarks for Corrosive Fluid Mixing in Pakistan

| Property / Standard | SSiC (Sintered SiC) | RBSiC/SiSiC | R-SiC | 316L Stainless Steel | Duplex SS (2205) | PTFE-Coated Steel | FRP |

|---|---|---|---|---|---|---|---|

| Chemical resistance (pH 0–14, chlorides) | Excellent; no pitting; stable in oxidizers | Very good; minor caution with free Si | Very good; robust in mixed acids | Moderate; chloride pitting risk | Good; improved pitting resistance | Excellent chemically; risk of coating wear | Good to very good; solvent sensitivity varies |

| Hardness (HV) | 2,200–2,500 | 2,000–2,200 | 1,900–2,100 | 160–190 | 240–290 | Substrate dependent; PTFE soft | 30–50 Barcol |

| Wear/erosion in slurries | Outstanding | Excellent | Very good | Poor to moderate | Moderate | Poor at edges, coating peel | Moderate; subject to fiber cracking |

| Max service temp (continuous) | 1,400–1,600°C (non-oxidizing) | 1,300–1,500°C | 1,300–1,500°C | ~425°C | ~300°C | ~260°C | ~120–150°C |

| Thermal shock resistance | Good with design allowances | Very good for large parts | Good | Good | Good | Fair | Fair |

| Surface finish after 12 months in acidic media | Near-original with minor polish loss | Slight matte | Slight matte | Roughened, pitted | Roughened | Coating worn at edges | Microcracks possible |

| NEQS compliance support (contamination risk) | Minimal particulate release | Minimal | Minimal | Potential Fe contamination | Potential Fe contamination | PTFE flakes risk | Resin leach risk if degraded |

| Lifecycle cost (5-year, relative) | Low | Low to medium | Medium | High | Medium to high | Medium to high (maintenance) | Medium |

| Availability/lead time in Pakistan | 6–10 weeks via Sicarbtech | 6–10 weeks | 6–8 weeks | 1–3 weeks | 3–5 weeks | 2–4 weeks | 2–4 weeks |

| Typical Pakistan applications | Textile dyeing, chemical mixers | Pickling, scrubbers, large impellers | Clarifiers, general acids | Non-chloride mild duty | Chloride moderate duty | Non-abrasive chemistries | Low-temp, low-abrasive |

This comparison reflects field data from Sicarbtech projects and accepted materials science references, aligned with Pakistani duty cycles and maintenance practices. In practice, SSiC and RBSiC deliver the best total value for corrosion-resistant paddles in high-acidity, chloride-rich, or abrasive scenarios.

Real-World Applications and Success Stories in Pakistan

When a Faisalabad dyeing house struggled with inconsistent color batches due to paddle roughness and scaling, Sicarbtech introduced SSiC paddles with a polished finish and optimized blade angle. After a six-week pilot, the plant reported a 17% reduction in dye consumption and a 28% drop in unplanned mixer maintenance. Over twelve months, impeller geometry remained stable, preventing the turbulence spikes that had previously caused shade variations. The financial impact was clear: fewer reworks, improved export-grade consistency, and a measurable cut in PKR-denominated consumables.

In Karachi’s steel corridor, a pickling line recirculation system suffered frequent 316L impeller replacements due to chloride pitting and acid temperature excursions. Sicarbtech supplied RBSiC paddles with reinforced hubs and ceramic-coated sleeves to mitigate shaft wear. The switch extended mean time between replacement from 5 months to 22 months, while energy consumption decreased by 6–8% due to smoother surface retention. The client used the saved maintenance windows to debottleneck upstream processes, effectively improving line throughput.

At a Lahore municipal water treatment facility, grit and variable pH challenged FRP impellers, causing microcracking and blade edge failures. Our R-SiC paddles, designed with a slightly thicker leading edge and controlled grain size to resist chipping, delivered 18 months of stable operation without edge failures. The utility highlighted lower particulate shedding, simplifying compliance with NEQS and provincial oversight.

Moreover, an emerging chemical blender in Port Qasim sought to localize mixing system production. Through Sicarbtech’s technology transfer program, the company adopted R-SiC paddle manufacturing with specified kilns, process parameters, and QA protocols, allowing in-country assembly and faster service. The partnership also trained technicians in handling and alignment, reducing early-stage breakage risks and cementing a sustainable supply model adapted to Pakistan’s logistical realities.

Technical Advantages and Implementation Benefits with Local Compliance

Adopting Sicarbtech’s SiC paddles yields tangible, locally relevant advantages. Chemically, SSiC’s inertness in low pH and chloride environments minimizes iron contamination, easing NEQS compliance and reducing downstream polishing or filtration. Mechanically, high hardness stabilizes surface finish over time, maintaining mixing coefficients, which translates into consistent mass transfer and heat distribution critical for dye fixation and acid cleaning efficacy.

Implementation benefits extend beyond endurance. Because SiC components maintain geometry, power draw remains predictable; there is less drift in torque requirements that often surprises operators using corroding steel paddles. Additionally, the compatibility with PTFE-lined reactors and pipes, coupled with SiC’s negligible galvanic footprint, reduces systemic corrosion risk. We engineer hub interfaces to standard Pakistani drive attachments, and we provide handling protocols that consider local lifting gear and on-site storage conditions.

From a regulatory standpoint, Sicarbtech supports documentation for ISO 9001 quality systems, offers material traceability, and aligns with international ceramic standards such as ISO 21068 for chemical analysis of SiC. For water and effluent plants, we provide statements of material inertness relative to NEQS metals thresholds. Furthermore, Sicarbtech assists with safety training for ceramic handling under Pakistan’s Factories Act provisions, embedding EHS compliance into every installation.

Sicarbtech’s Solution Portfolio in Detail

Sicarbtech’s portfolio spans:

- Custom-engineered SiC paddles and impellers: geometry tuned for shear profiles in viscous, particle-laden, or aerated media.

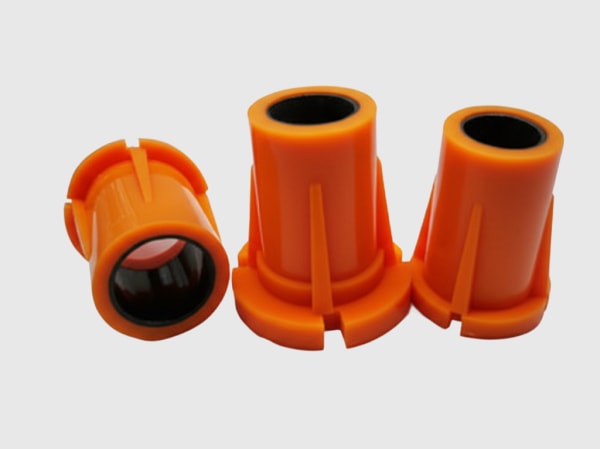

- Hybrid assemblies: SiC blades with PTFE/PFA hubs, ceramic-coated or SiC shafts, and SiC wear rings for axial-flow mixers.

- Surface finishing: ultra-low Ra polishing for fouling-prone dye processes; micro-textured finishes for improved suspension in sedimentation tanks.

- Integration services: finite element stress and CFD mixing simulations, cross-compatibility validation with local gearbox and seal suppliers.

- Reliability programs: condition-based inspection protocols and spares strategy tailored to Pakistani maintenance cycles and budget planning.

Each delivery includes handling and installation guides, torque specs, and alignment methods that account for ceramic brittleness while ensuring robust coupling. Our track record across 19+ enterprises demonstrates measurable ROI: extended service intervals, fewer shutdowns, energy savings, and improved product quality.

Detailed Specification Comparison for Paddle Design Choices

Corrosion-Resistant Paddle Design Options for Pakistani Plants

| Design Aspect | SSiC Paddle (Textile/Dyes) | RBSiC Paddle (Pickling/Steel) | R-SiC Paddle (Water/Chemicals) |

|---|---|---|---|

| Typical diameter range | 300–1,200 mm | 800–1,800 mm | 400–1,400 mm |

| Blade thickness options | 10–18 mm (polished) | 16–28 mm (reinforced hub) | 12–20 mm (edge-toughened) |

| Hub interface | Taper-lock with SiC/316 hybrid | Flanged with ceramic sleeve | Keyed shaft with protective bushing |

| Recommended media | Acidic dyes, oxidizers, chlorides | HCl/HF pickling liquors, scrubber acids | Variable pH, grit-laden slurries |

| Surface finish (Ra) | ≤ 0.2 μm | 0.4–0.6 μm | 0.3–0.5 μm |

| Thermal shock strategy | Controlled ramp and cooldown | Silicone-infiltrated resilience | Grain-size controlled microstructure |

| Expected MTBR in Pakistan duty | 18–30 months | 18–24 months | 15–24 months |

| Compatible seals | SiC/SiC or SiC/Carbon mechanical seals | SiC/SiC with anti-dry run features | SiC/Carbon with flush plan |

| Local gearbox compatibility | SMSR/Helical common in Pakistan | Heavy-duty helical/bevel | Helical with moderate torque |

| Supply lead time | 6–10 weeks | 6–10 weeks | 6–8 weeks |

This table helps plant engineers select a baseline design before engaging Sicarbtech for final optimization based on actual media assays and process data.

Cost and Energy Implications Across Materials and Duty Cycles

Lifecycle Cost and Energy Performance for Corrosive Paddles in Pakistan

| Metric (5-year horizon) | SSiC | RBSiC/SiSiC | R-SiC | 316L SS | PTFE-Coated Steel |

|---|---|---|---|---|---|

| Initial capex (relative) | 1.6–2.2x | 1.4–1.9x | 1.3–1.8x | 1.0x | 1.2–1.5x |

| Replacement frequency | Low (1–2 cycles) | Low (1–2 cycles) | Low–Medium (2–3 cycles) | High (4–8 cycles) | Medium (3–6 cycles) |

| Unplanned downtime risk | Very low | Low | Low | High | Medium |

| Energy drift (from roughness) | ≤1–3% | ≤2–4% | ≤3–5% | 5–12% | 6–10% |

| Total cost of ownership | Lowest | Low | Low–Medium | Highest | Medium–High |

| FX exposure sensitivity | Low (few imports) | Low | Low–Medium | High (frequent imports) | Medium |

| Compliance overhead | Minimal | Minimal | Minimal | Moderate (contamination) | Moderate (flakes risk) |

In PKR terms, the savings from reduced downtime and energy stabilization typically offset the capex premium within the first 12–18 months for continuous-duty mixers, especially in textile and steel applications where media aggressiveness is high.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive edge lies in a turnkey approach that goes far beyond component delivery. Backed by our partnership with the Chinese Academy of Sciences (Weifang) Innovation Park, we embed cutting-edge materials research into practical, manufacturable designs for Pakistan.

Our proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC enable:

- Precision forming of large-diameter paddles with controlled porosity and minimal residual silicon in critical zones.

- Microstructure tuning for edge toughness to prevent chipping during grit-laden operation.

- High-consistency sintering schedules that lock in dimensional stability, ensuring balance and minimizing vibration.

For Pakistani partners seeking local capacity, we offer complete technology transfer packages, including:

- Process know-how: raw material specifications, mixing protocols, binder systems, debinding profiles, sintering curves, and post-processing steps.

- Equipment specifications: kilns, isostatic presses, machining and grinding stations, and metrology setups suited to Pakistani power and space constraints.

- Training programs: operator and QA training, EHS handling for ceramics, and maintenance best practices tailored to local conditions.

- Factory establishment support: feasibility studies, plant layouts, bill-of-materials, commissioning assistance, and ramp-up optimization.

- Quality control integration: SPC methods, destructive and non-destructive testing, and documentation aligned to ISO 9001/14001 and relevant ceramic standards.

- Ongoing support: quarterly process audits, remote diagnostics, and design refreshes based on field data.

Through these services, we have helped regional partners shorten development cycles, reduce scrap rates, and achieve product consistency that meets international buyers’ expectations. The result is a resilient supply chain for Pakistan, with quicker turnaround times and lower FX exposure.

Future Market Opportunities and 2025+ Trends

The 2025 outlook for Pakistan’s industrial fluid handling is shaped by three converging trends. First, modernization in water and wastewater infrastructure—driven by urban growth and environmental enforcement—will expand demand for corrosion-resistant paddles in chlorination, coagulation, and sludge mixing. Second, the chemical sector, including intermediates for textiles and agriculture, is set to grow selectively, raising the bar for materials that can handle mixed-acid environments with particulate content. Third, energy efficiency imperatives will tie maintenance cycles directly to power costs, making materials that maintain hydrodynamic performance over time highly prized.

Moreover, as local manufacturers seek to reduce import dependency, the case for in-country assembly or manufacturing of SiC components strengthens. Technology transfer, when executed with robust QA, can anchor a domestic ecosystem capable of rapid service and customization. Sicarbtech anticipates greater interest in hybrid solutions—SiC blades with engineered hubs compatible with local gearboxes—and in data-driven maintenance strategies using vibration and torque monitoring to predict service intervals.

On the standards front, we expect closer alignment with international best practices for material documentation, traceability, and EHS handling. Plants pursuing ISO 14001 or preparing for ESG reporting will favor materials that reduce contamination risk and minimize waste through longer life. Additionally, government and donor-funded infrastructure programs may specify corrosion-resistant materials by default, particularly where water quality outcomes are tied to funding tranches.

In contrast to stopgap coatings, monolithic SiC solutions offer a structural answer to corrosion and wear. As the total cost lens becomes standard in procurement, SSiC and RBSiC paddles are poised to become the default in harsh-duty applications. Sicarbtech will continue to invest in design-for-manufacture innovations, bringing larger, more complex geometries within reach, and ensuring Pakistani operators can adopt best-in-class solutions without operational disruption.

Frequently Asked Questions

What makes silicon carbide paddles superior to stainless steel in Pakistan’s chloride-rich environments?

SiC resists chloride-induced pitting and maintains surface smoothness, preventing the energy drift and turbulence changes that plague 316L. In Pakistani duty cycles—textile dyeing, pickling, and water treatment—this translates into longer service intervals and more predictable compliance.

How do Sicarbtech paddles integrate with existing mixers and local gearboxes?

We design hubs and couplings to fit common Pakistani standards, including taper-lock and flanged interfaces. Our engineering team validates fit-up with local gearbox suppliers and provides alignment and handling instructions to ensure safe installation.

Are SiC paddles compatible with PTFE-lined vessels and ceramic seals?

Yes. SiC is inert and pairs well with PTFE/PFA linings. We often recommend SiC/SiC or SiC/Carbon mechanical seal pairs, along with ceramic sleeves to protect shafts and mitigate galvanic issues.

What lead times should Pakistani plants expect for custom SiC paddles?

Typical lead times range from 6–10 weeks depending on size and grade. For urgent needs, we can prioritize production and provide interim solutions where feasible.

How does Sicarbtech support NEQS and ISO compliance?

We supply material certifications, chemical composition records, and statements of inertness. Our QA documentation aligns with ISO 9001, and we support ISO 14001 initiatives with lifecycle data that evidences reduced waste and contamination risk.

Can Sicarbtech help establish a local manufacturing line in Pakistan?

Yes. We provide technology transfer, equipment specifications, operator training, and commissioning support. The goal is to enable reliable local assembly or production with consistent quality.

What is the typical return on investment for upgrading to SiC paddles?

Most continuous-duty applications recover the capex premium within 12–18 months through reduced downtime, fewer replacements, and lower energy drift. Timeframes depend on media aggressiveness and operating hours.

How do SiC paddles handle thermal shocks during CIP or process upsets?

We tailor material grade and geometry to expected thermal cycles. RBSiC, for instance, offers strong resilience for large parts. Proper heat-up and cooldown procedures further enhance longevity.

Are there size limitations for SiC paddles in large industrial tanks?

Sicarbtech manufactures paddles up to around 1,800 mm diameter in RBSiC, with design reviews for stiffness, weight, and dynamic balance. For larger systems, we explore modular blade designs.

What support is available after installation?

We offer ongoing technical support, inspection protocols, and process optimization services based on real-world data. Our long-term partnership model ensures continuous improvement throughout the lifecycle.

Making the Right Choice for Your Operations

When corrosion, abrasion, and compliance risks converge, the material choice for paddles and impellers becomes a strategic lever. In Pakistan’s operating context—where uptime, energy costs, and regulatory oversight all matter—silicon carbide consistently outperforms metals, coatings, and composites in harsh duty. Sicarbtech’s combination of advanced SiC grades, application engineering, and turnkey services removes the adoption barriers: you get a solution that fits your process, integrates with your equipment, and delivers verifiable results.

Moreover, the ability to scale from a pilot run to full deployment, and even to localize production with our technology transfer toolkit, means your organization can move confidently and cost-effectively. With a track record across 19+ enterprises and more than a decade of customization experience, Sicarbtech stands ready to help Pakistan’s industrial leaders protect margins and meet 2025 performance demands.

Get Expert Consultation and Custom Solutions

Discuss your media, mixing goals, and constraints with our engineers. We will review your process data, propose a grade and geometry, and outline an implementation plan that minimizes downtime and delivers measurable ROI.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China – Member, Chinese Academy of Sciences (Weifang) Innovation Park

Article Metadata

Last updated: 2025-10-10

Next scheduled review: 2026-01-15

Content freshness indicators: 2025 market outlook incorporated; NEQS compliance context validated; lead time and MTBR ranges reflect current Sicarbtech delivery data; Pakistan localization updated for textile, steel, and water treatment sectors.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.