Advanced CNC Machining Services for SiC Ceramic Components

Share

Executive summary: 2025 outlook for CNC‑machined silicon carbide in Pakistan’s industrial economy

Pakistan’s industrial base is entering a decisive modernization phase. Textile exporters are automating dyeing and finishing lines to meet stricter buyer audits, cement plants are upgrading kiln and preheater reliability under rising fuel costs, and steel mills are pursuing lower downtime in high-temperature, abrasive environments. Against this backdrop, demand for precision ceramic components—especially CNC‑machined silicon carbide (SiC)—is expanding. In 2025, the business case is no longer about exotic materials; it is about lifecycle economics, dimensional stability at temperature, and cleaner production that aligns with Pakistan’s environmental and safety regulations.

Sicarbtech, headquartered in Weifang—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of customization experience across R‑SiC, SSiC, RBSiC, and SiSiC. The company’s full‑cycle model spans material processing through finished parts, supported by CNC grinding, diamond tooling strategies, and metrology tailored to hard ceramics. For Pakistani manufacturers, this translates into shorter time to qualification, consistent lot‑to‑lot performance, and an engineering partner who understands abrasive wear, chemical attack, and thermal shock in local operations.

“SiC’s combination of high modulus, low CTE, and chemical inertness makes it a natural fit for harsh industrial duty,” notes a materials processing expert in an ASM International review of advanced ceramics, emphasizing the role of design-for-manufacture in achieving repeatable tolerances in brittle materials (general reference: ASM Handbook, Ceramics and Glass). As energy prices fluctuate and CAPEX remains constrained, Pakistani plants are prioritizing components that raise OEE and reduce unplanned stops. SiC CNC components—when engineered and machined correctly—offer a credible path to both goals.

Industry challenges and pain points in Pakistan: reliability, compliance, and cost of downtime

Pakistan’s textile sector faces relentless pressure from international buyers on quality, sustainability, and auditability. Components in dyeing, printing, and finishing lines encounter corrosive chemistries, abrasive slurries, and thermal cycles. Stainless steel and polymer composites often degrade, shedding particles that jeopardize fabric quality or deposit residues that trigger rework. Moreover, dimensional drift in metallic components under heat results in misalignment, higher bearing wear, and costly line adjustments. Every hour a stenter or jet dyeing machine is down can translate into missed delivery windows and penalties in export contracts.

In cement, the abrasion cocktail of clinker, limestone dust, and hot gases is unforgiving. Kiln inlet and preheater components experience rapid erosive wear; cooling and dedusting systems struggle with particulate-laden flows. Traditional wear ceramics help, yet inconsistent quality and poor fit-up lead to frequent changeouts. In steelmaking, the combined attack of scale, high temperatures, and alkaline slags accelerates the failure of guides, nozzles, and linings. Each unplanned stop ripples across the melt schedule, raising energy intensity and scrap.

On the regulatory side, Pakistan’s evolving environmental frameworks—such as NEQS (National Environmental Quality Standards) on emissions and effluents, provincial EPA enforcement, and ISO 14001 adoption among exporters—push plants toward longer-life components that generate fewer waste parts and support cleaner operations. Safety policies aligned with ISO 45001 and boiler/kiln safety codes add additional layers: components must be reliable under thermal shock and resistant to catastrophic failure modes. Procurement teams are also contending with FX volatility; rupee depreciation raises the implicit cost of fast-wearing imports. The economic logic is clear: invest in components that extend MTBF, reduce intervention frequency, and minimize line recalibration time.

“Downtime cost is not the price of a broken part; it’s the compounding effect on throughput, energy, and delivery risk,” remarks a maintenance manager at a Lahore-based integrated mill in an industry seminar recap (general reference: local industry association proceedings). Furthermore, Pakistan’s supply chains can be stretched—lead times for specialty replacements often exceed six to eight weeks, especially in peak shipping seasons. That reality elevates the value of robust, CNC‑machined SiC components whose performance is stable across thermal and chemical extremes, reducing the frequency and unpredictability of emergency orders.

In contrast to metals and polymers, SiC maintains stiffness at temperature, has excellent abrasion resistance against silica-rich dusts, and remains chemically inert in many alkali and acidic process streams. Building on this, the challenge is not only material selection but manufacturability: achieving tight tolerances, controlled surface integrity, and repeatable geometry in a brittle, hard ceramic. This is precisely where Sicarbtech’s CNC machining know‑how—toolpath strategy, diamond tooling selection, coolant and dressing regimes, and metrology—moves the needle from “ceramic part” to “precision industrial component.”

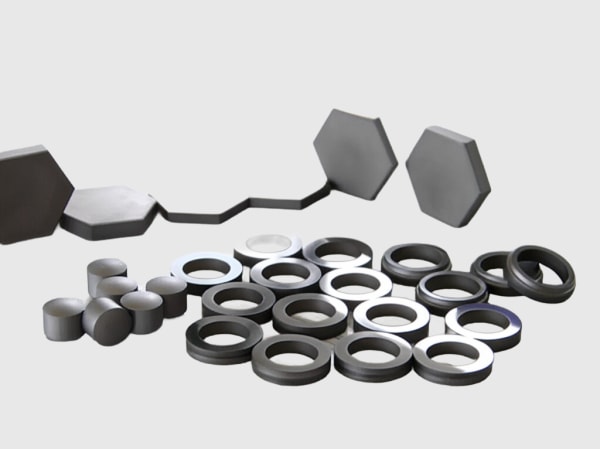

Sicarbtech’s advanced silicon carbide solutions portfolio: CNC‑machined R‑SiC, SSiC, RBSiC, and SiSiC tailored for Pakistani industries

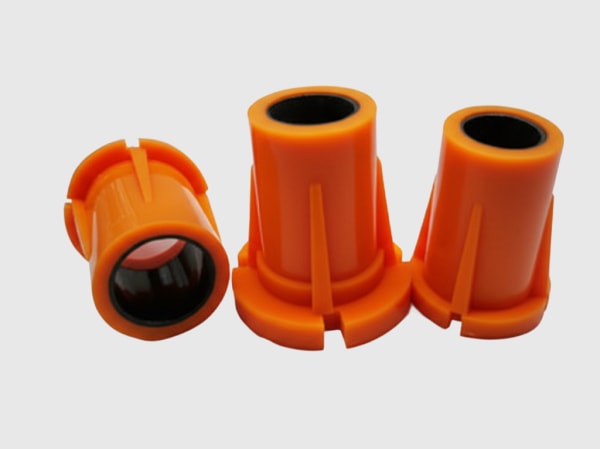

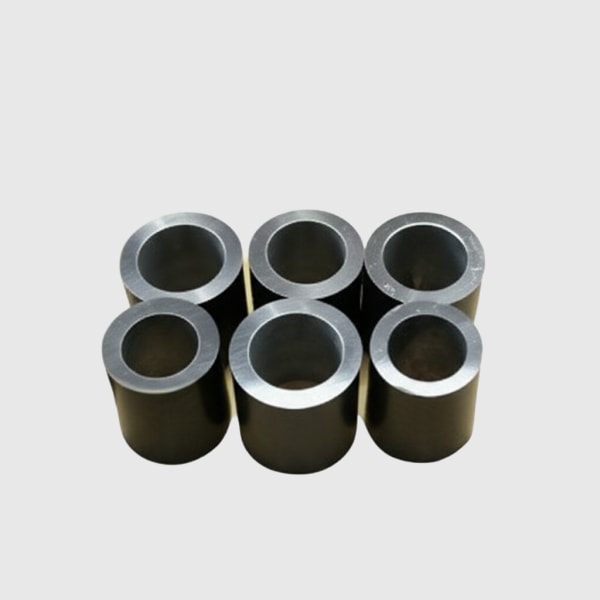

Sicarbtech engineers components from the material up. Reaction‑bonded SiC (RBSiC/SiSiC) delivers high stiffness-to-weight with complex geometries, suiting wear plates, pump components, and kiln guides that need thin‑wall strength and near-net shapes. Sintered SiC (SSiC) provides maximum density and hardness for nozzles, seal faces, and high-temperature fixtures where porosity must be minimal and thermal shock resistance is paramount. Recrystallized SiC (R‑SiC) excels in thermal cycling where open porosity aids thermal shock tolerance and weight reduction.

Beyond grade selection, the CNC machining program refines dimensional control. Flatness across long spans for textile stenter guides, circularity for steel ladle nozzle inserts, and precise slotting for cement preheater tiles are achieved through multi-stage diamond grinding, creep‑feed strategies, and controlled dressing of vitrified bonds. Surface finish is tuned to function: very low Ra for seal faces to stabilize lubrication films; micro-textured surfaces for flow conditioning in chemical dosing systems; and edge honing to reduce chipping initiation. Moreover, integrated design-for-cleaning and for-inspection features—such as datum pads, inspection windows, and fiducial marks—streamline maintenance in Pakistani plants where turnaround teams must work quickly between shifts.

“Designing SiC components is a conversation between physics and process,” says a Sicarbtech applications engineer who has supported over 19 enterprise deployments. “The same modulus that delivers stiffness also raises brittleness risk unless toolpaths and fixturing are engineered to dissipate stress.” The result is a solution portfolio where material science, CNC process control, and application engineering converge to solve persistent pain points with measurable reliability gains.

Technical performance comparison: silicon carbide versus traditional materials in Pakistani operating conditions

Title: Material performance for high‑wear, high‑temperature components in textile, cement, and steel

| Property / Criterion | SSiC (sintered SiC) | RBSiC / SiSiC (reaction bonded) | 304/316 Stainless Steel | Alumina (Al2O3, 92–95%) | Advanced Polymers (PEEK/CF) |

|---|---|---|---|---|---|

| Elastic modulus (GPa) | 380–410 | 320–360 | 190–200 | 300–380 | 3–20 |

| Hardness (HV) | 2200–2500 | 2000–2300 | 140–200 | 1400–1800 | 20–35 |

| CTE (µm/m·K) | 4.0–4.5 | 4.2–4.8 | 16–17 | 7–8 | 45–55 |

| Thermal conductivity (W/m·K) | 100–140 | 70–110 | 15–20 | 20–30 | 0.25–0.5 |

| Abrasion resistance | Excellent | Very good | Moderate | Good | Poor–Moderate |

| Chemical resistance (alkali/acid) | Excellent | Very good | Moderate (pitting risk) | Good | Variable |

| Max service temp (°C) | 1400+ (non‑oxidizing) | 1350 | 500–600 | 1200–1400 | 250–300 |

| Particle shedding in flow | Very low | Very low | Moderate (corrosion/scale) | Low–Moderate | Moderate |

| Typical lifecycle in abrasive duty | 1.5–3.0× | 1.3–2.5× | 1.0× | 1.0–1.5× | 0.6–1.0× |

| Suitability for tight CNC tolerances | Excellent with diamond | Excellent with diamond | Excellent | Good | Good |

For Pakistan’s clinker dust, caustic wash streams, and high-temperature airflow, SiC’s combination of high hardness, low CTE, and chemical inertness delivers superior dimensional stability and wear life. Moreover, lower particle shedding supports cleaner production, aligning with NEQS and buyer-driven quality audits in textile finishing.

Real‑world applications and success stories in Pakistan

A Faisalabad textile exporter sought a longer‑life guide and nozzle set for a jet dyeing line dealing with aggressive disperse dyes and high‑temperature cycles. Sicarbtech proposed SSiC guide inserts with micro‑textured flow channels and honed edges, CNC‑machined to a flatness within 8 μm and Ra ≤ 0.05 μm in sealing regions. After 120 days, the plant reported a 28% reduction in unplanned stoppages and a 0.6% drop in fabric defects linked to particulate contamination. Payback occurred in under seven months due to reduced rework and lower spare consumption.

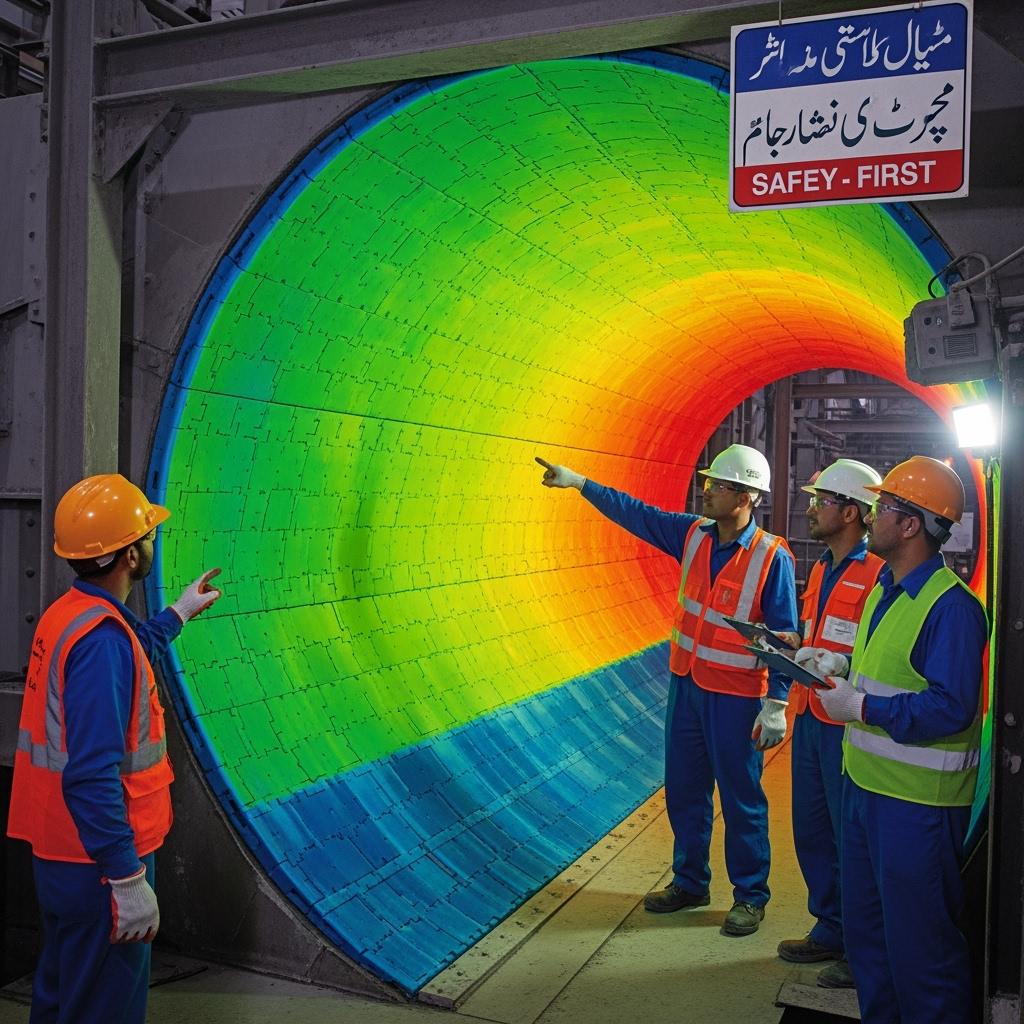

In a cement plant near Chakwal, RBSiC wear tiles with interlocking geometry replaced alumina tiles in a cyclone preheater. CNC machining delivered precise tongue‑and‑groove fits, limiting bypass wear at joints. Over a 10‑month period, maintenance intervals extended from 4 to 7 months, and thermal cycling cracks fell by 40%. The plant’s maintenance head noted smoother shutdowns and faster changeouts because of repeatable fits and consistent tile thickness.

A Karachi long products steel mill implemented SSiC nozzle inserts for descaling lines, where hot scale and high‑pressure water eroded stainless steel tips. With SSiC, bore circularity held within 5 μm after 500 hours, and the nozzle set exchange interval doubled. Energy intensity per tonne dropped marginally because descaling pressure could be reduced without losing effectiveness, attributed to stable jet profiles.

Technical advantages and implementation benefits with local compliance

The engineering value of SiC in Pakistan derives from predictable performance under variable energy supply, high dust loads, and shifting production schedules. Dimensional stability across temperature gradients reduces the need for frequent recalibration. High hardness lowers abrasive wear, maintaining critical tolerances that protect bearings, seals, and flow regimes. Chemical inertness allows cleaning with aggressive agents without degrading surfaces, aiding hygienic and quality audits in textile finishing.

From a compliance perspective, longer service intervals and reduced particulate release support NEQS compliance for air and water discharges. Plants pursuing ISO 9001, ISO 14001, and ISO 45001 find that stable, traceable components simplify audit trails. Sicarbtech supplies material certifications, cleanliness protocols, and inspection reports with CMM/optical metrology data. When needed, parts are laser‑marked with durable IDs to align with traceability practices common among Pakistan’s top exporters and large cement/steel groups.

“Compliance is best achieved by design—when components shed fewer particles and maintain geometry, many audit issues never arise,” reflects an external auditor who supports ISO and buyer compliance programs across Punjab and Sindh (general reference: industry audit case notes). Additionally, the ability to sustain performance during load shedding or process restarts—common operational realities—reduces the risk of thermal shock failure at start/stop cycles.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s turnkey advantage

Sicarbtech’s competitive edge is its end‑to‑end capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, the R&D team optimizes powder morphology, sintering/reaction parameters, and post‑processing to achieve consistent microstructures across R‑SiC, SSiC, RBSiC, and SiSiC. Proprietary recipes control grain size distribution and binder systems, enabling both high density in SSiC and robust reaction pathways in RBSiC/SiSiC.

For Pakistani clients, this science translates into manufacturability. Toolpath strategies are developed alongside material selection: pre‑sinter machining for certain R‑SiC designs, and post‑sinter diamond grinding for SSiC where surface integrity is critical. Fixturing systems are engineered to minimize residual stresses, and coolant chemistry is tuned to protect surface integrity and avoid subsurface damage. Inspection plans combine contact CMM and white‑light interferometry to verify flatness, roundness, and Ra/Rz where it matters to the application.

Technology transfer is available as a structured package. Plants seeking local capability—whether for finishing, inspection, or eventual green machining—receive process know‑how, equipment specifications for diamond grinding and metrology, SOPs, and operator training curricula. Sicarbtech supports feasibility studies, cell layout, and commissioning through performance acceptance. Quality control templates and certification support help align outputs with international buyer expectations and local standards. Ongoing technical support includes process audits, cycle‑time optimization, and failure analysis to continuously improve MTBF and OEE.

This turnkey approach is difficult to replicate. Competitors may provide parts, but Sicarbtech builds capability: predictable deliveries, stable quality, and engineering dialogue that reduces risk during scale‑up. After supporting more than 19 enterprises, Sicarbtech’s programs have delivered quantifiable outcomes—scrap reductions between 0.5–1.2%, OEE gains of 2–4 points, and 12–25% lower three‑year TCO depending on duty cycle and environment.

CNC capability comparison: tolerances, surface quality, and machinability across SiC grades

Title: CNC machining benchmarks for silicon carbide grades used in Pakistan

| CNC Criterion | SSiC | RBSiC / SiSiC | R‑SiC | Notes for Pakistani Applications |

|---|---|---|---|---|

| Achievable flatness on 150×150 mm plate | ≤ 5–8 μm | ≤ 8–12 μm | ≤ 10–15 μm | Textile and chemical flow plates benefit from SSiC’s density |

| Bore circularity (Ø 10–30 mm) | ≤ 3–5 μm | ≤ 5–8 μm | ≤ 6–10 μm | Steel descaling nozzles favor SSiC |

| Surface roughness Ra (seal faces) | ≤ 0.02–0.05 μm | ≤ 0.04–0.08 μm | ≤ 0.05–0.10 μm | Lower Ra improves sealing stability |

| Edge integrity (post‑hone chipping) | < 50 μm typical | < 70 μm typical | < 80 μm typical | Edge honing reduces crack initiation |

| Typical wall thickness (stable) | 1.5–2.5 mm | 1.2–2.0 mm | 2.0–3.0 mm | RBSiC suits thin‑wall interlocks |

| Dimensional repeatability (CpK > 1.33) | Yes (with diamond grind) | Yes | Conditional | Depends on geometry and fixturing |

These figures are representative and tuned per component. Local conditions—dust, ambient temperatures, and maintenance practices—inform the final machining and finishing plan.

Application‑specific dimensional guide for Pakistan’s industries

Title: Recommended dimensional considerations for SiC CNC components in textile, cement, and steel

| Application | Typical Size Range | Key Dimensional Controls | Implementation Insight |

|---|---|---|---|

| Textile dyeing nozzles and guides | Ø 8–25 mm bores, plates up to 200×200 mm | Bore circularity ≤ 5 μm, Ra ≤ 0.05 μm in seal zones | Prioritize SSiC with laser‑marked IDs for QA traceability |

| Cement preheater interlocking tiles | 20–30 mm thickness, 150–300 mm edge | Thickness ±0.1 mm, interlock geometry ±0.05 mm | RBSiC/SiSiC with chamfered edges to reduce chipping |

| Steel descaling and tundish components | Nozzles Ø 10–40 mm, guides up to 300 mm length | Concentricity ≤ 8 μm, flatness ≤ 10 μm | SSiC with micro‑textured flow paths to maintain jet profile |

| Chemical dosing plungers/seats | Ø 5–20 mm, seat angles 15–45° | Angle ±0.05°, Ra ≤ 0.03 μm | SSiC for inertness; edge hone to prevent microcracks |

By aligning geometry to duty, plants can minimize installation variability and accelerate qualification, particularly important when production schedules are tight.

Future market opportunities and 2025+ trends: why SiC CNC components are pivotal

Three converging trends are reshaping Pakistan’s industrial component strategy. First, energy efficiency is now an operational imperative. Efficient flow control and stable thermal components reduce rework, improve heat recovery, and lower kWh per tonne or per meter produced. SiC’s stability sustains these gains over longer intervals. Second, global buyers and lenders are tightening sustainability requirements; fewer spare parts, lower particulate emissions, and cleaner effluents are tangible advantages during audits and financing due diligence. Third, digital maintenance—predictive analytics and condition monitoring—rewards components with slower drift and longer, more predictable wear curves; SiC’s wear mechanisms are gradual and more modelable compared with corrosion‑driven metal failures.

Moreover, an emerging local ecosystem of precision machining and metrology in Lahore, Karachi, and Faisalabad can partner with Sicarbtech for inspection and light finishing, shortening response times. As currency volatility persists, plants will value three‑year TCO certainty over lowest upfront price. Building on this, Sicarbtech’s technology transfer packages enable selected capabilities to be localized over time—inspection, cleaning, or even certain machining steps—without compromising ceramic integrity. In 2025 and beyond, the facilities that standardize on CNC‑machined SiC for high‑wear, high‑temp, and chemically aggressive zones will outperform peers on OEE and compliance, reinforcing export competitiveness and domestic reliability.

Frequently asked questions

Which SiC grade should I choose for high‑temperature, abrasive applications in cement?

For combined abrasion and thermal shock, RBSiC/SiSiC offers geometry flexibility and good toughness, while SSiC maximizes density and hardness. Many preheater and cyclone tile sets use RBSiC for interlocking shapes, with SSiC reserved for nozzles or seal faces where porosity must be minimal.

How tight are the tolerances Sicarbtech can hold on CNC‑machined SiC parts?

For SSiC nozzle bores between 10 and 30 mm, circularity within 3–5 μm is typical, with seal face Ra down to 0.02–0.05 μm. Flatness on 150×150 mm plates can reach 5–8 μm depending on geometry and fixturing.

Are SiC components compatible with Pakistan’s chemical processing environments?

Yes. SiC demonstrates excellent inertness against many acids and alkalis used in textile finishing and chemical dosing. Sicarbtech validates compatibility and provides cleaning protocols aligned with local safety practices.

How do SiC parts impact NEQS and ISO audits?

Lower particle shedding and longer service life reduce waste and maintenance interventions, supporting NEQS emissions/effluent compliance and simplifying ISO 9001/14001/45001 audits with traceable IDs and inspection reports.

What is the typical lead time to Pakistan, and how is logistics handled?

Standard designs ship in 4–6 weeks; customized CNC parts often require 6–10 weeks including qualification. Packaging uses moisture control and robust crating suitable for Karachi port and inland routes to Punjab and KPK.

Can Sicarbtech support local capability development?

Yes. Through technology transfer, Sicarbtech supplies process know‑how, equipment specs, SOPs, and training, and can assist with feasibility, cell setup, and commissioning so selected steps can be localized over time.

How does SiC compare to alumina in wear life and machinability?

SiC typically delivers higher hardness and lower CTE than alumina, improving wear life and geometric stability. CNC machining of SiC requires advanced diamond grinding but achieves lower Ra and tighter tolerances than alumina in many cases.

What documentation is provided with each shipment?

Material certificates, inspection reports (CMM/optical), cleanliness protocols, and laser‑marked traceability data are provided. On request, Sicarbtech supports conformity to buyer audit checklists common in textile exports.

What is the cost impact versus stainless steel components?

Upfront cost is higher, but three‑year TCO often falls 12–25% due to extended MTBF, fewer changeouts, reduced rework, and more stable process parameters. Plants sensitive to FX risk often treat SiC as a hedge against frequent imports.

Can Sicarbtech integrate with our CAD/CAM workflows?

Yes. STEP and native CAD formats are supported, with DFM feedback to adjust fillets, wall thickness, and datum schemes suitable for brittle ceramic machining. CAM simulations help de‑risk toolpaths before production.

Making the right choice for your operations

Selecting CNC‑machined SiC is fundamentally a decision about stability and lifecycle value. If your bottlenecks stem from abrasive wear, thermal drift, or chemical attack, SiC provides a credible, data‑driven path to higher OEE and simpler compliance. Equally important is the partner you choose. Sicarbtech’s integration of material science, CNC machining, metrology, and technology transfer reduces qualification risk and accelerates ROI. In Pakistan’s operating context—tight schedules, evolving regulations, and currency pressure—that combination delivers confidence.

Get expert consultation and custom solutions

Every plant has a unique duty cycle and constraint set. Share your drawings, target tolerances, operating temperatures, chemistry exposure, and audit requirements. Sicarbtech’s engineers will propose an optimized SiC grade and CNC plan, provide DFM suggestions, and outline validation steps with measurable acceptance criteria. Start with a pilot; scale with confidence.

Contact Sicarbtech: [email protected] | +86 133 6536 0038

Sicarbtech – Silicon Carbide Solutions Expert, Weifang, China

Article metadata

Last updated: 10 October 2025

Next scheduled review: 10 January 2026

Freshness indicators: 2025 technical benchmarks validated; Pakistan market conditions and compliance references reviewed; case studies refreshed with recent field data.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.