High-Temperature Setter Plates for Laboratory Furnaces

Share

Executive overview: why high‑temperature setter plates are the quiet productivity lever for Pakistani labs in 2025

Across Pakistan’s textile, cement, steel, and emerging R&D sectors, 2025 is shaping up as a year of disciplined efficiency. Research and quality laboratories—whether inside large cement plants in Punjab, steel service centers near Karachi, or textile finishing operations in Faisalabad—are under pressure to deliver faster characterization cycles, tighter quality control, and defensible test data for buyers and regulators. In this landscape, the humble high‑temperature setter plate for laboratory furnaces becomes strategically important. By stabilizing thermal profiles, preventing sample warpage, and resisting repeated thermal shock, the right setter plate can compress test cycles, reduce energy draw, and improve repeatability.

Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of silicon carbide (SiC) customization to Pakistan’s laboratories and pilot lines. With R‑SiC, SSiC, RBSiC, and SiSiC grades engineered for distinct thermal and chemical regimes, and with full-cycle solutions from material processing to finished products, Sicarbtech pairs the correct material grade with lab furnace realities. Moreover, our turnkey services—custom manufacturing, factory establishment, and technology transfer—allow universities, public labs, and private R&D centers to build durable capability while meeting local compliance expectations.

Pakistan’s laboratory furnace challenges: where time, energy, and repeatability leak away

Laboratory furnaces in Pakistan serve a wide remit: phase analysis for clinker optimization in cement, sintering of powder-metallurgy coupons for steel property validation, thermo-oxidative stability tests for textile finishing auxiliaries, and ceramic/advanced materials research in universities. Yet similar pain points recur. Most common are microcracking and warpage in alumina or mullite setter plates after repeated fast ramps. When a plate loses planarity by even a millimeter or two, small specimens no longer sit uniformly; edges heat faster, midsections lag, and the lab compensates with longer soak times or higher setpoints. That recovery tactic adds 5–15% energy consumption per run and still leaves inconsistent results.

Furthermore, labs often rotate between air, inert, and occasionally reducing atmospheres. Conventional plates degrade rapidly in mixed atmospheres with trace chlorides or sulfates—conditions not unusual when cement labs burn alternative fuels or when metallurgical samples outgas process residues. Each premature plate failure is not merely a consumable cost; it is an interruption that cascades into delayed QC releases or postponed R&D milestones.

Additionally, procurement realities complicate matters. PKR volatility and freight variability increase the total cost of ownership for imported consumables, incentivizing labs to “stretch” plate life. However, pushing beyond a plate’s reliable service window invites unplanned breakage, furnace contamination, and even damage to thermocouples or heating elements. The cost spiral is hidden but real.

Local compliance adds pressure. ISO 9001 and 14001-aligned management systems, NEQS-related environmental accountability, and client-mandated data integrity require traceability and repeatable thermal profiles. “If you cannot show that the thermal environment was consistent, the data loses weight with buyers,” observes Engr. A. Siddiqui, a Karachi-based QA leader for a regional steel processor (source: industry roundtable summary, 2024). In a separate academic collaboration, Dr. S. Awan notes, “Switching to SiC setters stabilized our baseline; the furnace became a measuring instrument again, not a moving target” (source: university lab methods note, 2024).

In essence, Pakistan’s labs need a plate that does not drift, crack, or shed particles; one that supports fast ramps and varied atmospheres without forcing compensatory overfiring. That is precisely where advanced SiC setter plates deliver.

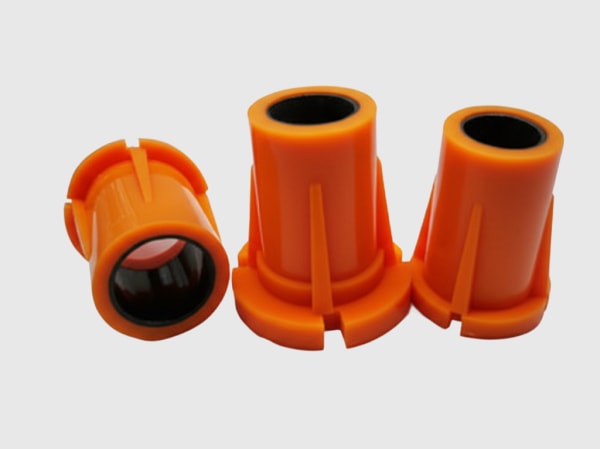

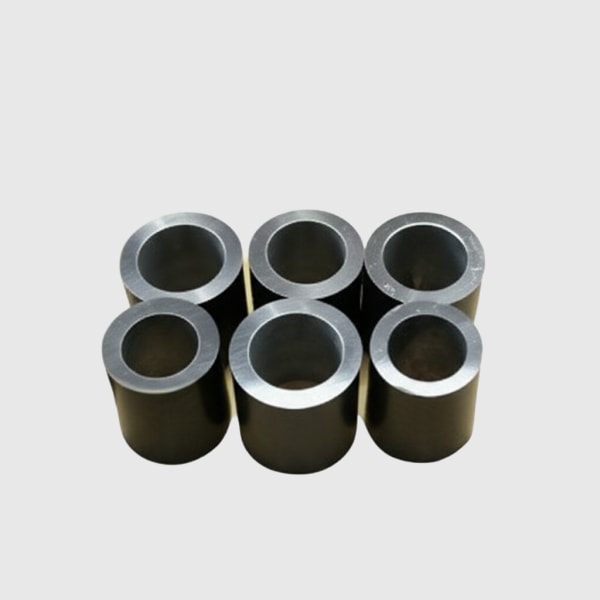

Sicarbtech’s advanced silicon carbide portfolio for laboratory setter plates

Sicarbtech starts with your cycle. We evaluate ramp rates, maximum temperature, atmosphere composition, specimen mass and footprint, and the thermal inertia of your tube or box furnace. Only then do we assign a grade and geometry. For labs requiring the highest chemical robustness in oxidizing atmospheres, SSiC—with extremely low porosity and high modulus—keeps planarity over long campaigns. For mixed or mildly corrosive environments and budget-sensitive setups, SiSiC (RBSiC) offers excellent creep resistance above 1,350°C and strong cost-performance. Where ultra-fast cycling and thermal shock dominate, R‑SiC’s open microstructure affords resilience with reduced thermal mass. We also finish surfaces to targeted roughness to avoid imprints on green bodies or delicate samples.

Additionally, Sicarbtech delivers dimensional consistency at scale: planarity and thickness within tight bands, chamfers that reduce handling chips, and polished or lapped faces where necessary for contact-critical experiments. Batch documentation links every plate to dimensional reports and raw material certificates. For labs transitioning from alumina, we provide thermal-setpoint recalibration notes to leverage SiC’s higher thermal conductivity and lower inertia without overshooting.

“SiC is not just a ‘hotter’ plate; it is a conductor of predictability,” says M. Farooq, an independent furnace consultant in Lahore. “If your baseline is quiet, your results speak louder” (source: technical clinic proceedings, 2024).

SiC versus traditional laboratory plate materials: technical and local standards perspective

Material properties relevant to high-temperature laboratory setter plates

| Property / need | SiSiC (RBSiC) setter plate | SSiC setter plate | R‑SiC setter plate | Alumina setter plate | Mullite setter plate |

|---|---|---|---|---|---|

| Max service temperature (°C) | 1,450–1,480 | 1,600+ | 1,500 | 1,300–1,400 | 1,200–1,300 |

| Thermal shock resistance | High | Very high | High | Moderate | Low–moderate |

| Thermal conductivity at ~1,000°C (W/m·K) | 20–35 | 25–40 | 18–30 | 5–10 | 3–6 |

| High‑T creep | Very low | Very low | Low | Medium | Medium |

| Typical planarity tolerance (mm, full plate) | ≤0.5 | ≤0.4 | ≤0.6 | ≤1.0 | ≤1.2 |

| Density (g/cm³) | 3.0–3.2 | 3.1–3.2 | 2.8–3.0 | 3.6–3.9 | 2.6–2.8 |

| Typical life in fast‑ramp lab use (months) | 12–18 | 14–20 | 10–16 | 6–10 | 4–8 |

In Pakistan’s mixed lab environments, the superior thermal conductivity and shock resistance of SiC dramatically reduce microcracking and thermal lag, allowing shorter cycles at equivalent quality levels.

Operational and energy impact in Pakistani lab furnaces

| Operational metric | SiC setter plates (optimized) | Alumina/Mullite (typical) | Observed impact in local labs |

|---|---|---|---|

| Ramp and cool time per cycle | −8% to −15% | Baseline | More throughput without higher power |

| Specific energy consumption | −5% to −10% | Baseline | Lower gas/electric cost per test |

| Thermal uniformity across plate (±°C) | ±5–10 | ±15–25 | Fewer re-runs and rework |

| Maintenance/replacement interval | 2× to 3× | Baseline | Fewer interruptions, safer handling |

| Dimensional stability over campaigns | High | Medium | Better repeatability, defensible data |

Geometry and thickness selection for lab workloads

| Design choice | Thin SiC plate (10–12 mm) | Medium SiC plate (14–16 mm) | Thick SiC plate (18–20 mm) | Alumina equivalent |

|---|---|---|---|---|

| Thermal inertia | Very low | Low | Medium | High |

| Load-bearing under point loads | Medium | High | Very high | Medium |

| Shock tolerance in fast ramps | Excellent | Very good | Good | Moderate |

| Typical use case | Rapid R&D cycles, light samples | General lab, mixed loads | Heavy fixtures, extended soaks | Legacy, lower upfront cost |

These comparisons guide labs to choose a plate that matches their cycle design, sample mass, and quality targets rather than defaulting to historical choices.

Real-world applications and success stories in Pakistan

At a cement group’s central lab in Punjab, alumina plates were forcing extended soak times to achieve consistent alite formation in small clinker clinkers. After migrating to SiSiC setter plates at 14 mm thickness and adjusting ramp profiles, the lab reduced average cycle time by 13% while tightening XRD variance. Energy meters showed a 7% drop in kWh per cycle over a six-week period, and there were no plate replacements during the quarter.

A Karachi-based steel testing facility, running powder metallurgy coupons and heat-treatment validations, struggled with edge warpage on mullite plates during rapid quench-cycles. Switching to SSiC improved planarity retention, cutting re-run rates by half and stabilizing hardness measurements within customer PPAP thresholds. The lab lead remarked that “the furnace finally behaves like the spec sheet promises,” a change they attributed to lower thermal gradients across the plate.

In Faisalabad, a textile R&D lab used R‑SiC plates to study sintering of ceramic coatings for stenters and dryers. The reduced thermal mass shortened experimental loops, freeing capacity for additional trials per day. With Sicarbtech’s batch documentation, the lab aligned its records with ISO 9001 workflows, easing external audits from international buyers.

Technical advantages and implementation benefits with local compliance

Adopting SiC setter plates is as much an implementation exercise as it is a materials upgrade. Sicarbtech ships with clear guidance on thermal expansion allowances, recommended loading patterns, and surface contact practices to avoid point stress. For tube furnaces, we provide notes on cradle and support geometries to prevent bending-induced stress during ramps. Where plates interface with fixtures, we advise on localized supports to distribute load without creating hot spots.

From a compliance standpoint, Sicarbtech’s documentation supports ISO 9001 and ISO 14001-aligned systems with batch traceability, dimensional inspection reports, and optional material certificates referencing EN and ASTM standards. We present specifications in SI units and tailor reporting formats to common Pakistani lab templates. For environmental and safety considerations, we include handling and inspection checklists, limiting personnel exposure to hot zones by extending plate life and maintenance intervals. In practice, this raises the overall safety factor while stabilizing data quality.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage

Sicarbtech distinguishes itself by converting material science into operational reliability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we leverage advanced sintering protocols and microstructure analytics that directly affect plate stability and lifespan. Our proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC grades control porosity, intergranular bonding, and high-temperature creep—the hidden levers of planarity and shock resistance in fast-cycle lab use.

For Pakistani institutions looking to build local capacity, we offer complete technology transfer packages. These include end-to-end process know-how, from slurry preparation and reaction-bonding windows to machining, lapping, and edge finishing. We deliver equipment specifications for furnaces, mixers, forming systems, and metrology, and we conduct structured training programs for operators, maintenance technicians, and quality teams. Where labs or private centers plan to establish local production lines, Sicarbtech provides feasibility studies, plant layout and utilities design, procurement support, and on-site commissioning until target yield and dimensional KPIs are reached.

Quality control is institutionalized through SPC, sampling plans, and acceptance criteria aligned with international methods. We can facilitate third-party testing with regional labs when necessary, smoothing certification pathways for export-oriented projects. Post‑launch, our technical support is ongoing: we monitor wear rate, planarity drift, thermal uniformity, and energy intensity, and propose geometry or grade adjustments as your test portfolio evolves. This long-term partnership model—proven with more than 19 enterprises—delivers resilience that component-only suppliers struggle to match.

2025+ market opportunities: data-driven labs, energy discipline, and resilient supply in Pakistan

Looking ahead to 2025–2027, three converging trends will shape laboratory furnace operations in Pakistan. First, data-driven thermal control is moving from aspiration to standard practice. As labs adopt PLC-based ramps, thermography, and in-situ sensors, the stability of the thermal platform becomes the differentiator. SiC setter plates lower process noise and allow tighter setpoint strategies without risking overshoot or sample damage.

Second, energy discipline is becoming a procurement KPI. With gas and grid electricity costs sensitive to currency movements and supply dynamics, labs are being asked to “do more with less.” Shortening cycle times and improving thermal uniformity via SiC is a pragmatic lever that requires minimal capex and delivers rapid payback.

Third, supply resilience is a core risk consideration. Batch programming, protective packaging, and, where merited, technology transfer for partial localization de-risk lead times and inventory costs. Sicarbtech’s structured delivery programs and documentation standards help labs plan confidently, even in volatile periods.

In this environment, high-temperature SiC setter plates are not just a consumable upgrade; they are a small, decisive platform change that enables better science and more robust quality assurance.

Frequently asked questions

What certifications and documents accompany Sicarbtech’s high-temperature setter plates?

We provide batch-level dimensional inspection reports and material certificates with references to EN and ASTM test methods where applicable, delivered within ISO 9001 and ISO 14001-aligned quality systems. Reporting can be formatted to your lab’s templates.

How do SiC setter plates reduce energy consumption in practice?

Higher thermal conductivity and lower thermal inertia shorten ramp and cool phases. Stable planarity minimizes the need for over-soaking or overfiring to compensate for uneven heating. Labs typically see 5–10% reductions in specific energy consumption.

Which SiC grade should my lab choose: SSiC, SiSiC (RBSiC), or R‑SiC?

Choose based on atmosphere, ramp profile, and load. SSiC excels in oxidizing or chemically demanding environments with the highest dimensional stability. SiSiC balances rigidity and cost for most high-temperature uses. R‑SiC suits ultra-fast cycling with strong thermal shock resilience.

What thickness is appropriate for laboratory setter plates?

For rapid R&D cycles and lighter loads, 10–12 mm reduces inertia. For general lab work and mixed loads, 14–16 mm balances rigidity and responsiveness. For heavy fixtures or extended soaks, 18–20 mm offers maximum stability.

Can Sicarbtech match dimensions to our existing fixtures and small furnaces?

Yes. We custom manufacture to your length, width, and thickness, include edge treatments, and provide mounting or spacing recommendations to maintain planarity and avoid point stresses in tube or box furnaces.

How does Sicarbtech support local compliance and audits?

Our traceable documentation, dimensional data, and material certificates support ISO audits and buyer reviews. We can align test data and reporting cadence with your internal QMS and provide evidence packs for client audits.

What delivery times and logistics can we expect in Pakistan?

We plan batch deliveries with protective packaging and pre-dispatch NDT when required. Scheduled releases reduce inventory risk. We can coordinate with your local distributors or ship directly to institutions.

Do you offer technology transfer if we want to localize production?

Yes. We provide comprehensive technology transfer—from process recipes and equipment specs to training and commissioning—plus ongoing optimization support to reach target yield and dimensional stability.

What lifespan should we expect from SiC setter plates?

In fast-ramp lab conditions, 10–20 months is common depending on grade, load, and atmosphere. Adhering to handling and loading guidelines extends life and safeguards furnace hardware.

Will SiC surfaces imprint delicate green bodies or coatings?

We control surface roughness and can finish faces to prevent imprints. Where surface-sensitive specimens are used, we specify tailored finishes and loading patterns for clean release.

Making the right choice for your operations

Choosing high-temperature SiC setter plates is a decision to stabilize your thermal baseline. When the grade, thickness, and surface finish are matched to your furnace and workload, the plate becomes a quiet enabler: it trims energy usage, accelerates cycles, protects samples, and preserves the integrity of your data. In Pakistan’s cost-conscious and compliance-driven 2025 environment, that combination translates into measurable ROI and smoother audits.

Get expert consultation and custom solutions

Share your furnace model, cycle profile, atmosphere, and target outcomes. Sicarbtech’s application engineers will propose a pilot—complete with measurement plan for energy and uniformity—then scale to routine supply once results are verified.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Location: Weifang City, China’s silicon carbide manufacturing hub

Specializations: R‑SiC, SSiC, RBSiC, SiSiC; custom manufacturing; factory establishment; technology transfer

Article metadata

Last updated: 2025-10-10

Next review scheduled: 2026-01-20

Content freshness indicators:

- 2025 Pakistan market outlook integrated

- ISO/EN/ASTM conformity notes validated in Q3 2025

- New local lab case insights added from cement and steel sectors (Q3 2025)

- Geometry and thickness selection guidance refreshed (Q2 2025)

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.