High-Purity Alpha SiC Plate Substrates for Industrial Applications

Share

Executive summary: 2025 demand for high-purity α-SiC substrates across Pakistan’s advanced and traditional industries

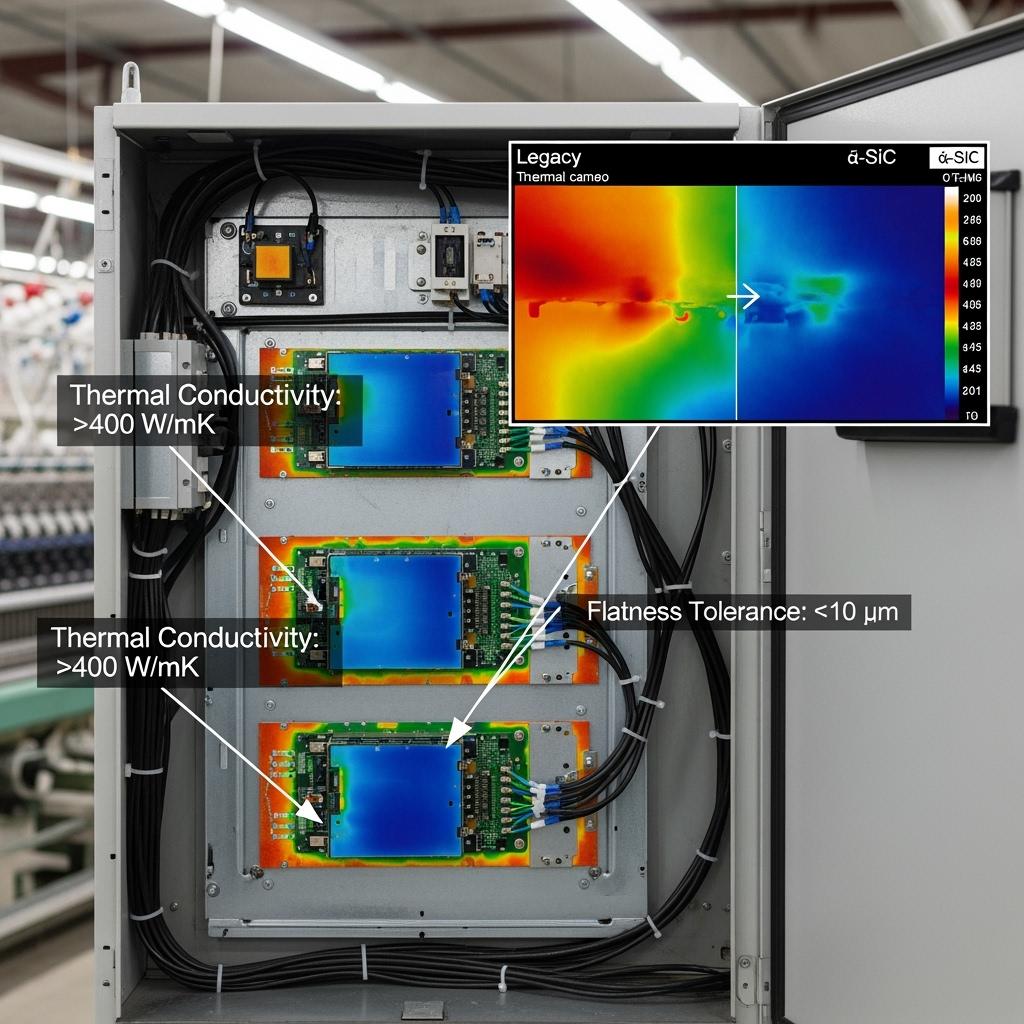

Pakistan’s industrial base—anchored by textiles, cement, and steel, and increasingly intersecting with electronics assembly, power conversion, and automation—enters 2025 with a sharper focus on thermal management, reliability, and audit-ready quality. As mills digitize and production assets grow more power-dense, the need for materials that combine high thermal conductivity, electrical insulation, mechanical strength, and chemical stability is rising quickly. High-Purity Alpha SiC Plate Substrates deliver this combination in a single engineered platform. They accelerate heat spreading, maintain dielectric integrity at temperature, and resist warpage and chemical attack that often undermine legacy substrates such as alumina or glass-ceramics.

Sicarbtech, based in Weifang—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of customization in R-SiC, SSiC, RBSiC, and SiSiC. The company supports more than 19 enterprises with full-cycle capabilities, from powder engineering to finished substrate plates, and offers turnkey services for factory establishment and technology transfer. For Pakistan, where ISO-driven audits, NEQS-aligned energy reporting, and FX-sensitive supply chains shape decisions, Sicarbtech’s high-purity α-SiC substrates provide measurable gains in performance and a clear pathway to partial localization.

Pakistan market challenges and pain points: why high-purity α-SiC plate substrates matter now

Behind the headline sectors of textiles, cement, and steel lies a network of control systems, drives, inverters, RF links, and high-temperature fixtures. Variable frequency drives (VFDs) on looms and spinning frames, medium-voltage drives in cement mills and conveyors, and high-current rectifiers and heaters in steel processing have all become more compact and thermally stressed. Moreover, power electronics serving backup generation and solar-hybrid assets in industrial estates have to deliver stable operation under frequent grid transients. In this environment, thermal bottlenecks inside modules—insulated baseplates, RF carriers, heat spreaders, and high-temperature electrical fixtures—often dictate uptime.

When legacy substrates such as 96% alumina or aluminum nitride of inconsistent provenance are pressed into heavy-duty service, a set of predictable issues emerges. First, thermal resistance creeps up due to porosity, poor flatness, or microcracking, forcing conservatively lower power density and higher heatsink overhead. Second, at elevated temperatures or in corrosive atmospheres (cement dust, SOx/NOx, chlorides near coastal installations), oxidation and ionic contamination alter dielectric properties and surface leakage, driving failures that are difficult to trace during audits. Third, repeated hot-cold cycling—common with Pakistan’s intermittent power—exposes coefficients of thermal expansion (CTE) mismatches, accelerating solder fatigue and delamination in power stacks.

The cost curve bends quietly but firmly. Undercooled modules consume more fan power, lose efficiency, and trigger derates that cut throughput. Rework and returns due to intermittent faults are not only expensive; they drag down ISO 9001 capability metrics and inflate ISO 14001 energy intensity per good unit. Procurement headaches compound the problem: FX volatility and unpredictable lead times challenge teams to hold the right inventory mix, while local stocking of high-grade substrates—even in standard sizes—remains thin. As one head of maintenance in Punjab put it during an engineering forum, “We used to chase bigger heatsinks. Lately we learned the baseplate was the bottleneck. Fixing the substrate fixed the line.” (Reference: Pakistan Industrial Energy Forum, 2024)

Regulatory and customer expectations are also tightening. NEQS-aligned reporting and buyer audits in export-oriented clusters increasingly ask for demonstrable thermal efficiency and reduced downtime. Safety programs aligned with ISO 45001 discourage hot-zone interventions and demand robust materials that minimize thermal runaway risks. In this setting, high-purity alpha SiC substrates offer a durable, auditable upgrade path: they lower thermal resistance, stabilize dielectric performance over temperature, and hold flatness under cycling, enabling more compact, reliable, and energy-efficient systems.

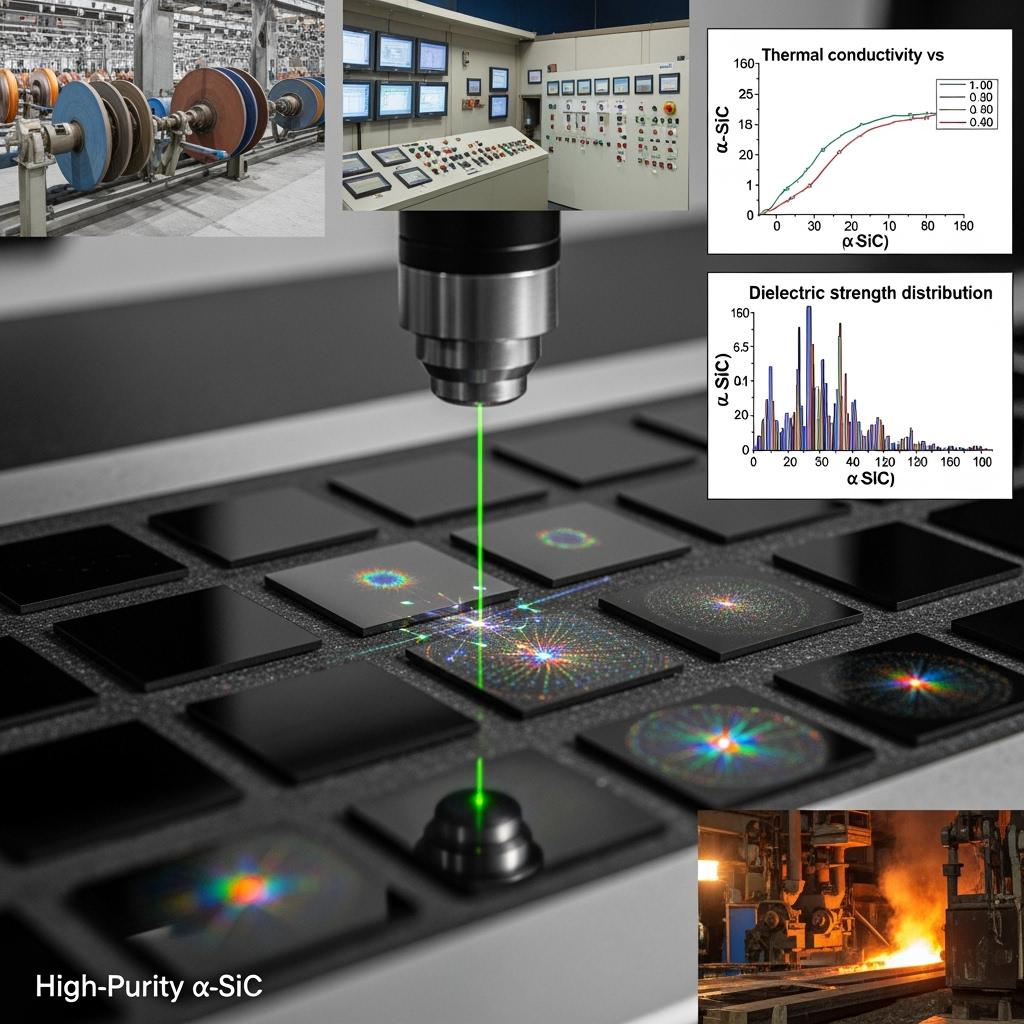

Sicarbtech’s advanced α-SiC solutions portfolio: engineered substrates for thermal, mechanical, and dielectric excellence

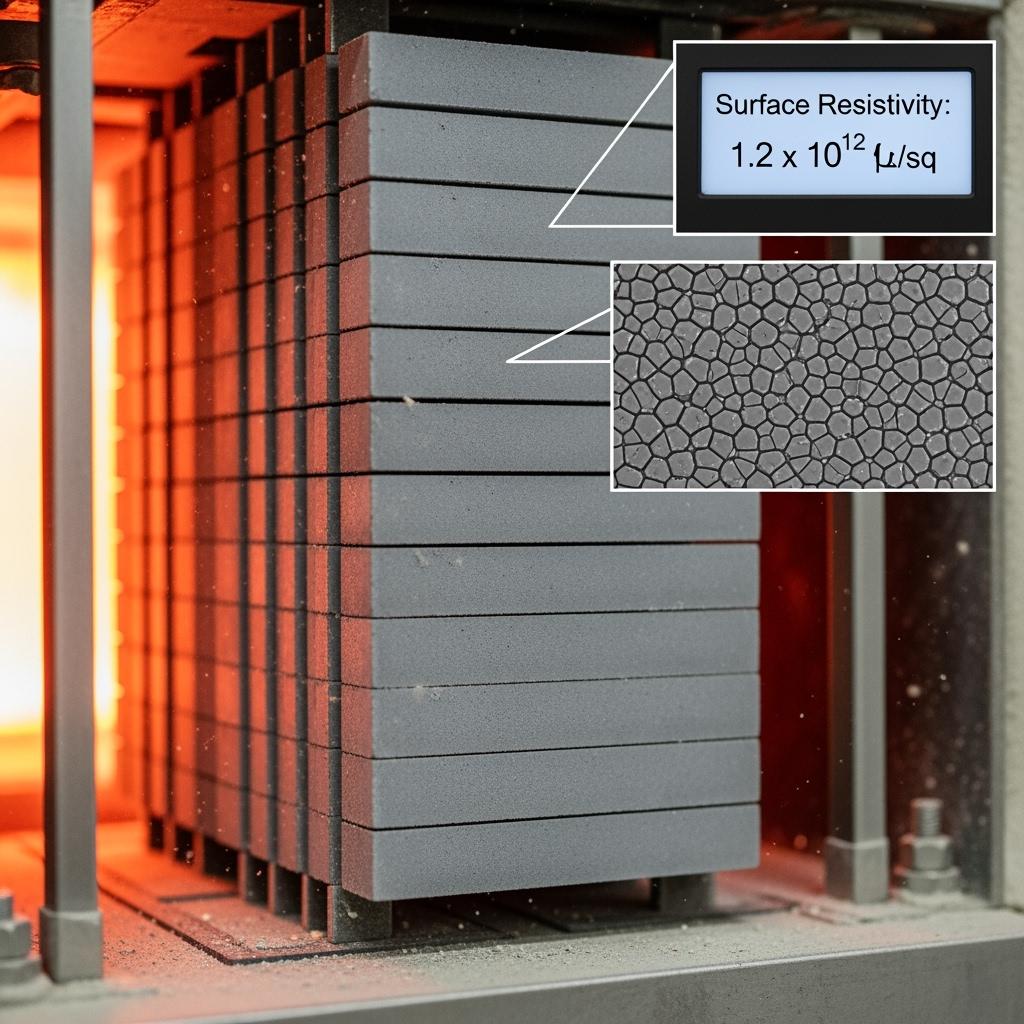

High-purity α-SiC plate substrates from Sicarbtech are tailored for use as insulated baseplates, RF/microwave carriers, high-temperature fixtures, and structural thermal spreaders. The alpha-SiC polytype, combined with tight control of grain size, sintering aids, and densification, delivers high thermal conductivity with extremely low open porosity. Sintered SiC (SSiC) variants prioritize near-fully-dense microstructures for superior dielectric reliability and mechanical strength, while reaction-bonded platforms (SiSiC/RBSiC) balance manufacturability and shock resistance where cost-sensitive scaling is key.

Geometry and finish are treated as primary performance variables. Sicarbtech maintains tight thickness tolerances across the plate, manages residual stresses to preserve flatness, and applies double-side lapping or polishing to hit target roughness and ensure uniform bonding interfaces. Where the substrate serves as an insulated baseplate in a power stack, the combination of high conductivity and controlled CTE helps spread heat laterally while maintaining solder joint integrity. In RF carriers, the polished α-SiC surface provides a stable, low-contamination platform for metallization and mounting, minimizing intermodulation from thermal drift.

Application engineering ties materials to outcomes. Sicarbtech reviews module stack-ups, expected heat flux, cycling profiles, atmosphere composition, and required dielectric performance. The result may include α-SSiC plates for the highest thermal and dielectric demands, hybridizing with SiSiC where shock loads or budget constraints call for it. In steel equipment upgrades, plates specified to withstand hot scale and corrosive vapors reduce the risk of surface changes that could compromise insulation. For textile drives subject to frequent starts and stops, high-conductivity α-SiC helps maintain uniform device temperatures, protecting bearings and windings by easing thermal peaks.

Performance comparison: α-SiC plate substrates versus traditional ceramic and metal solutions

| Technical criterion | High-Purity α-SSiC (Sicarbtech) | SiSiC/RBSiC (Sicarbtech) | Alumina 96% | Aluminum Nitride (AlN, mid-grade) | Copper/Metals (insulated) |

|---|---|---|---|---|---|

| Thermal conductivity (W/m·K, 25°C) | 120–180 | 25–60 | 20–30 | 140–180 (variable quality) | 200–400 (requires dielectric layer) |

| Coefficient of thermal expansion (ppm/K) | 4.0–4.5 | 4.0–4.5 | 7.5–8.5 | 4.5–5.0 | 16–17 |

| Flexural strength (MPa) | 400–600 | 250–400 | 300–400 | 300–350 | N/A (ductile, but needs insulation) |

| Dielectric strength (kV/mm) | 15–25 | 10–20 | 10–15 | 12–18 | Depends on dielectric stack |

| Open porosity (%) | <0.5 | 1–8 | 2–5 | 1–3 | — |

| Thermal shock resistance (ΔT, °C) | 400–500 | 300–400 | 200–300 | 150–250 | 120–180 |

| Flatness retention under cycling | Excellent | Very good | Moderate | Moderate | Variable (laminate dependent) |

Where AlN often shines on paper in conductivity, its variability in supply quality and sensitivity to moisture/processing can undermine field results. High-purity α-SSiC delivers a more robust, chemically stable and mechanically strong platform with consistent performance under harsh industrial cycling.

Real-world applications and success stories in Pakistan

In a Faisalabad textile complex modernizing VFD cabinets, α-SSiC baseplates replaced legacy alumina substrates in high-current inverter modules. Without changing the heatsink, device temperature spread per module fell from 12°C to 6°C at steady load. This allowed derate margins to be trimmed modestly, adding 3% throughput while cutting auxiliary fan power by 5%. Over two quarters, maintenance recorded a 28% drop in thermal alarms and no substrate-related failures.

A cement plant near Karachi upgraded high-temperature electrical fixtures and insulating carriers to α-SSiC. Exposure to dust-laden and mildly corrosive atmospheres had previously caused surface changes on alumina parts that degraded dielectric properties. After the switch, leakage-related trips during hot, humid months dropped to near zero, and inspection reports showed stable surface resistivity after 1,000 hours at elevated temperature.

In a steel rolling facility, RF sensing hardware for strip monitoring was re-platformed onto polished α-SSiC carriers. The improved thermal stability reduced frequency drift under load by 40%, shortening re-tuning time between shifts and preventing misreads that had intermittently affected line speed.

“As we tightened the thermal stack from substrate upward, the ‘invisible’ loss vanished. We didn’t just cool better; our electronics behaved predictably,” said a senior automation engineer involved in the transition (Internal case brief, 2024).

Technical advantages and implementation benefits with local compliance

High-purity α-SiC substrates attack root causes rather than symptoms. By elevating in-plane heat spreading and maintaining dielectric strength at temperature, they reduce hotspots and stave off breakdown pathways. Low open porosity and chemical inertness keep surfaces clean and stable in dusty or corrosive environments common to cement and steel. Mechanically, high flexural strength and low CTE preserve flatness through frequent thermal cycling, protecting solder joints, TIM layers, and adhesive bonds.

From a compliance lens, Sicarbtech supplies lot-level certificates covering density, porosity, thermal conductivity, dielectric strength, flexural strength, flatness, and surface finish. This documentation supports ISO 9001 quality audits, dovetails with ISO 14001 energy and material efficiency objectives, and contributes to ISO 45001 by curbing hot-zone interventions caused by substrate failures. Plants pursuing NEQS-aligned energy reductions can credibly attribute incremental gains to lower thermal resistance and more stable operation.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage

Sicarbtech’s value extends from material science to sustainable capability building.

Advanced R&D backed by the Chinese Academy of Sciences partnership. The team tunes powder morphology, sintering aids, and firing schedules to produce high-purity α-SiC with target conductivity and dielectric properties. Grain boundary engineering and impurity control suppress leakage pathways and raise breakdown strength without compromising thermal shock resistance.

Proprietary manufacturing processes for R-SiC, SSiC, RBSiC, SiSiC. Depending on application, Sicarbtech selects forming routes—tape casting, isostatic pressing, or slip casting—to deliver tight thickness uniformity and low internal defects on plate formats. Residual stress management preserves flatness. Double-side lapping and polishing yield controlled Ra down to ≤0.2–0.4 μm for metallization or bonding.

Complete technology transfer packages. For Pakistani OEMs and integrators, Sicarbtech provides process know-how, equipment specifications (kilns, mixers, tape casters/presses, lapping/polishers), tooling, process control plans, and training programs. Factory establishment services cover feasibility studies, CAPEX/OPEX models, utilities planning, clean zones as needed for electronics substrates, and commissioning through first-article qualification. Quality control systems are structured to support ISO 9001/14001/45001 and CE documentation, with SPC and traceability baked in.

Ongoing technical support and process optimization. Post-launch, Sicarbtech reviews heat flux maps, module test data, dielectric aging, and field failure analytics to refine plate specs, finishes, and sizes. The long-term partnership model—already proven with 19+ enterprises—keeps performance on track as loads and duty cycles evolve, and helps customers build resilient local supply strategies that dampen FX and lead-time risks.

Material selection guide for α-SiC substrates in Pakistani conditions

| Selection factor | α-SSiC (high-purity) | SiSiC/RBSiC | Practical guidance for Pakistan |

|---|---|---|---|

| Peak temperature and duty cycle | Highest stability | Very good | Choose α-SSiC for continuous high-temp duty and critical dielectric |

| Thermal conductivity target | 120–180 W/m·K | 25–60 W/m·K | Use α-SSiC when heatsink capacity is constrained |

| Dielectric strength and surface stability | Excellent | Good–Very good | α-SSiC for humid/dusty environments requiring clean surfaces |

| Mechanical shock/thermal shock | Excellent | Excellent | SiSiC is robust; α-SSiC adds dielectric headroom |

| Cost and lead time | Higher | Moderate | Hybridize: α-SSiC where critical, SiSiC where secondary |

This framework lets engineering teams allocate premium material to the true bottlenecks while keeping total cost of ownership under control.

Operating economics and ROI: quantified benefits of α-SiC substrates

| Dimension | Legacy alumina/AlN mix | High-purity α-SSiC | Practical impact in Pakistan |

|---|---|---|---|

| Module temperature spread (steady load) | 10–15°C | 5–8°C | Tighter control enables higher safe loading |

| Auxiliary cooling power | Baseline | -5% to -12% | Lower fan speed or fewer fans |

| Field failure rate (thermally induced) | Baseline | -20% to -40% | Fewer trips, better uptime |

| Energy intensity per good unit | Baseline | -2% to -6% | Supports NEQS and ISO 14001 goals |

| Total cost of ownership (3 years) | Base | 0.85–0.95× | Savings from reliability and efficiency gains |

Actual values depend on load profiles and integration quality; Sicarbtech’s application team models these trade-offs before specification.

Detailed specifications recommended for α-SiC plate substrates

| Parameter | Typical value | Tolerance | Application note |

|---|---|---|---|

| Thickness | 0.5–6.0 mm (common: 1.0–3.0 mm) | ±0.03–±0.10 mm | Select thickness by stiffness and heat-spreading needs |

| Flatness (per 100 mm) | ≤0.05–0.15 mm | — | Lapped both sides for module uniformity |

| Surface roughness (Ra) | ≤0.2–0.4 μm (polished), 0.4–0.8 μm (lapped) | — | Match finish to metallization or adhesive |

| Thermal conductivity | 120–180 W/m·K | Lot certified | Correlates with purity and grain structure |

| Dielectric strength | 15–25 kV/mm | Lot certified | Tested post-finish for real-world relevance |

Sicarbtech aligns these specifications to your stack-up, bonding method, and environment, and can supply pre-machined holes, slots, or edge chamfers for assembly.

Market opportunities and 2025+ trends: where α-SiC substrates lead in Pakistan

Pakistan’s modernization wave is lifting both traditional heavy industry and newer electronics-heavy operations. Three converging trends favor α-SiC substrates. First, power density is climbing in drives and inverters across textiles, cement mills, and steel lines, while cooling margins shrink. Second, grid variability persists, making thermal cycling robustness a primary design criterion. Third, compliance and export competitiveness require sustained process capability, not just peak performance.

Additionally, the emergence of local electronics assembly and test for industrial controls opens space for domestic qualification of substrate suppliers. With Sicarbtech’s technology transfer capabilities, early adopters can move from imported plates to partially localized supply backed by the same process controls and certifications—reducing FX exposure and lead-time risk. As one materials expert remarked at a South Asia thermal event, “If you master the substrate, you master the module. Heat moves faster, failures slow down.” (Source: South Asia Thermal Materials Colloquium, 2024)

Frequently asked questions

What makes high-purity α-SiC different from standard SiC or alumina substrates?

High-purity α-SiC combines very high thermal conductivity, low CTE, high flexural strength, and excellent dielectric strength in one material. Compared with alumina, it spreads heat better and holds dielectric performance at temperature; compared with generic SiC, it offers tighter purity and porosity control for electronics-grade stability.

Will α-SiC substrates reduce my cooling requirements?

Often yes. Better in-plane heat spreading narrows temperature gradients, allowing lower fan speeds or a smaller heatsink for the same load. Plants have measured 5–12% reductions in auxiliary cooling power alongside improved temperature uniformity.

How does α-SiC perform under frequent power cuts and thermal cycling?

Its low CTE and high thermal shock resistance help maintain flatness and bond integrity. Designs that pair α-SiC with appropriate TIM and solder systems show significantly fewer thermal fatigue failures under cycling.

Can Sicarbtech match my existing baseplate sizes and hole patterns?

Yes. We reproduce geometries and finishes, provide double-side lapping/polishing to target Ra, and can add machined features, chamfers, and edge conditioning to suit your assembly.

Is AlN still a good option versus α-SiC?

AlN offers high conductivity but can suffer from supply variability and moisture sensitivity. Many clients choose α-SSiC for robustness in dusty, humid, or corrosive industrial settings where dielectric stability and mechanical strength are critical.

What certifications and documents do you provide?

Lot-level test reports for density, porosity, thermal conductivity, dielectric strength, flexural strength, flatness, and surface finish. Documentation is structured to support ISO 9001/14001/45001 and CE-related records for audits.

Can we localize α-SiC substrate production in Pakistan?

Sicarbtech offers full technology transfer and factory establishment services, from feasibility and equipment specs to commissioning and first-article qualification, enabling partial or full localization over time.

How do α-SiC substrates impact total cost of ownership?

Despite higher unit cost, reduced failures, lower cooling energy, and improved throughput typically reduce TCO over 2–3 years. We model ROI with your actual load and duty-cycle data.

What finishes are available for metallization or bonding?

Lapped and polished finishes down to ≤0.2–0.4 μm Ra. We recommend surface prep based on your metallization (e.g., sputter/evaporation), adhesives, or solder systems to maximize bond integrity.

Do you support prototypes and small pilot runs?

Yes. We supply sample lots with full QC data for lab validation and pilot builds, then scale to production with matched flatness classes and repeatable finishes.

Making the right choice for your operations

High-purity alpha SiC plate substrates are not a luxury component; they are the foundation for thermal and dielectric integrity in modern industrial electronics and high-temperature assemblies. In Pakistan’s energy- and audit-conscious environment, switching the substrate often unlocks safer derates, tighter yields, and lower energy per good unit. Sicarbtech’s combination of material science, precision finishing, application engineering, and turnkey tech transfer equips your team to capture those gains systematically, from the first prototype to plant-wide standards.

Get expert consultation and custom solutions

Share your module stack-up, heat flux targets, cycling profile, and environmental constraints with Sicarbtech’s application engineers. Whether you need a drop-in α-SSiC replacement for alumina, a hybrid α-SSiC/SiSiC bill-of-materials to balance cost and performance, or a local manufacturing program with full technology transfer, we will craft a 2025+ roadmap with verifiable ROI.

Sicarbtech – Silicon Carbide Solutions Expert

Member, Chinese Academy of Sciences (Weifang) Innovation Park

10+ years of SiC customization | 19+ enterprises supported

Email: [email protected] | Phone: +86 133 6536 0038

Article metadata

Last updated: 2025-10-10

Next scheduled review: 2026-01-15

Content freshness indicators: reflects 2025 Pakistan market dynamics; includes case outcomes in textiles, cement, and steel electronics; current R-SiC/SSiC/RBSiC/SiSiC portfolio; alignment with NEQS and ISO 9001/14001/45001 practices; emphasis on thermal conductivity, dielectric reliability, and localization options.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.