Industrial Silicon Carbide Solutions for Pakistan’s High-Temperature and Abrasive Applications

Share

Executive summary: 2025 outlook for silicon carbide solutions in Pakistan’s textile, cement, and steel industries

Pakistan’s industrial economy heads into 2025 balancing cost pressure, energy constraints, and increasingly stringent quality and safety expectations. Textile mills in Punjab and Sindh are modernizing heat-setting, singeing, and stenter lines while optimizing gas consumption. Cement plants across Punjab and Khyber Pakhtunkhwa continue kiln upgrades and alternative fuel co-processing, demanding refractory components that survive alkali attack and thermal shock. Steel re-rolling mills and integrated steel operations seek longer life for burners, tuyeres, and wear liners as scrap variability increases. In this context, advanced silicon carbide (SiC) materials—R-SiC, SSiC, RBSiC, and SiSiC—offer a robust path to higher availability, lower specific energy, and predictable maintenance intervals.

Sicarbtech, based in Weifang City—the heart of China’s silicon carbide manufacturing ecosystem and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of SiC customization experience to Pakistan. The company supports over 19 enterprises with full-cycle solutions, from powder processing and sintering to precision finishing and assembled components. While this pillar page addresses a broad portfolio of industrial silicon carbide solutions, we also align with cluster topics around durable refractory burner nozzles made from high alumina, because in many Pakistani kilns and furnaces, hybrid solutions blending SiC hardware with high-alumina inserts or tips deliver the best lifecycle cost.

Building on this, Sicarbtech integrates custom manufacturing, technology transfer, and factory establishment services so local OEMs, EPCs, and plant operators can capture performance gains with faster logistics and lower currency risk.

Expanded industry challenges and pain points in Pakistan’s operating reality

Energy pricing volatility and gas allocation uncertainty remain central concerns, particularly for textile processors relying on natural gas for stenters, dryers, and singeing burners. When flame shape drifts due to worn nozzle throats or refractory spalling, mills overfire to maintain temperature, raising specific energy consumption and risking fabric quality. Moreover, as mills shift to blends of RLNG and other fuels, burner components face different flame temperatures and condensate chemistries, accelerating oxidation and alkali attack. A plant manager in Faisalabad put it plainly: “The cost of a single shift lost to burner misfire dwarfs the price of a high-end nozzle, but procurement often learns this after the third breakdown” (industry interview, 2024).

Cement producers contend with alkali vapors, sulfur cycles, and clinker dust abrasion that erode conventional refractories and metallic parts. Burner tips, coal nozzle throats, and tertiary air components suffer combined thermal shock and particle impingement. Frequent thermal cycling during load-following operations exacerbates crack initiation. Each unscheduled shutdown can mean clinker quality excursions, downstream mill instability, and missed dispatch targets, adding both direct maintenance costs and opportunity losses.

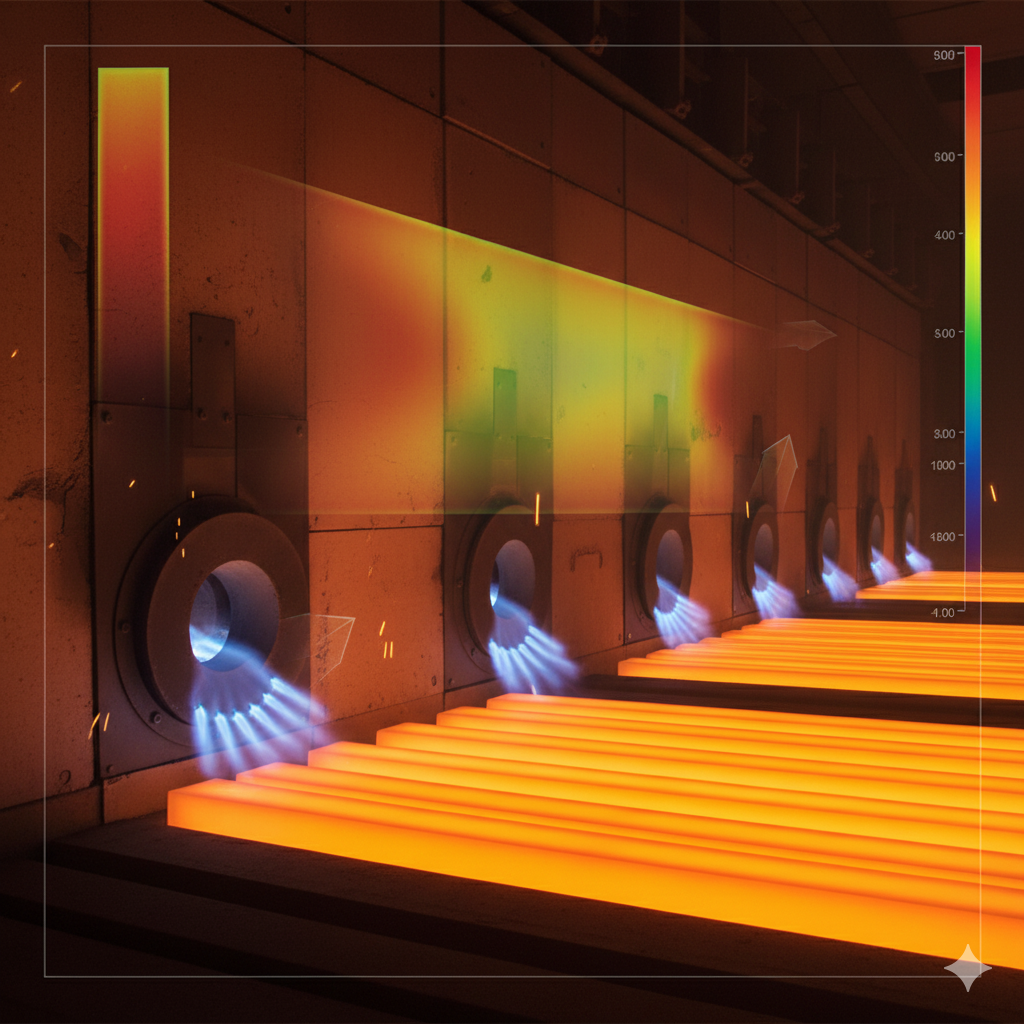

Steel operations face scale, slag, and oxidizing atmospheres that are punishing for metallic lance tips and burner blocks. As scrap ratios increase and temperature windows tighten, operators need components that hold geometry under thermal shock. In reheat furnaces, deviation in burner orifice profile distorts flame impingement patterns, creating temperature non-uniformity that translates into dimensional variation and higher rejection rates.

Compliance adds complexity. Pakistani standards and guidance often equate to adoption of well-recognized international frameworks—ISO 9001 for quality management, ISO 14001 for environmental controls, and plant safety practices aligned with OSHA-type requirements—while large exporters must also meet customer-driven audits. The Pakistan Environmental Protection Agency and provincial EPAs increasingly scrutinize stack emissions and energy use, nudging plants toward components that stabilize flame and reduce excess air. “Regulatory pressure is less about punitive fines and more about market access—global buyers want evidence of process stability,” notes a Lahore-based energy auditor (trade seminar summary, 2025).

Currency volatility and import lead times remain persistent hurdles. A sudden PKR depreciation can make emergency imports prohibitive. Consequently, maintenance strategies that lengthen component life and reduce the number of SKUs in critical spares deliver disproportionate value. In contrast, lower-grade refractory or metal parts that appear cheaper at purchase often raise total cost of ownership through accelerated wear, higher gas usage, and labor-intensive replacements.

Advanced Silicon Carbide Solutions Portfolio engineered by Sicarbtech

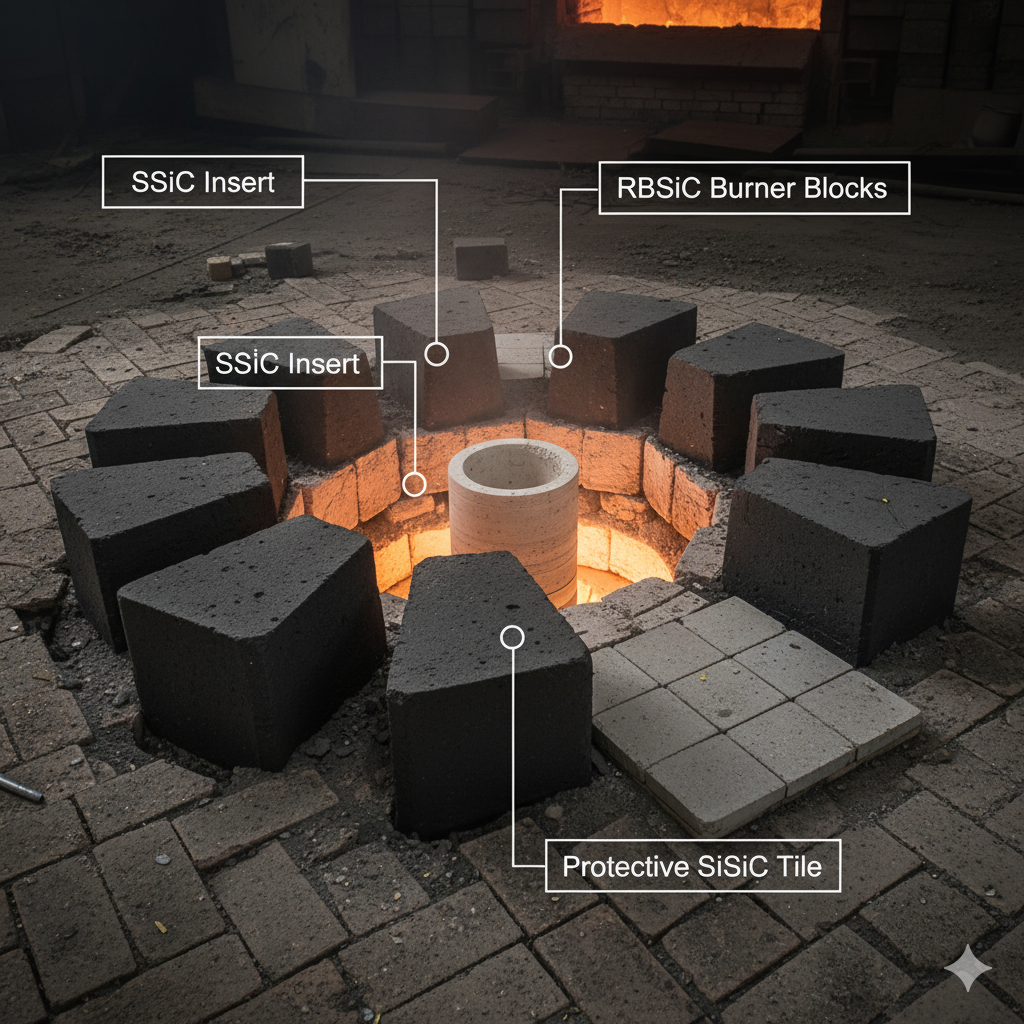

Sicarbtech’s portfolio is designed around four SiC families—R-SiC, SSiC, RBSiC, and SiSiC—each tuned for specific combinations of strength, thermal shock resistance, oxidation resistance, and machinability. Rather than offering catalog pieces alone, Sicarbtech co-engineers components with Pakistani plant teams and OEMs to fit real operating envelopes: flame temperatures, particle loads, fuel chemistry, and maintenance windows. For burner-associated applications, silicon carbide blocks, throats, tiles, and sleeves can be paired with high-alumina or zirconia-toughened tips where swirl stabilization or edge toughness is critical. Additionally, RBSiC burner blocks deliver outstanding creep resistance at sustained high temperatures, while SSiC inserts provide the best corrosion resistance in aggressive atmospheres with chlorides or sulfur species.

Because Pakistani plants often operate mixed fleets of European, Japanese, and local equipment, Sicarbtech focuses on integration. Dimensional matching to legacy burner manifolds, custom joint geometries to avoid crevices, and engineered shrink-fit of SiC sleeves into steel housings are typical engineering services. Moreover, when the use case demands, Sicarbtech manufactures high alumina burner nozzles as companion parts, creating a harmonized system with SiC support structures. This reduces thermal gradients and prevents mismatched thermal expansion from causing premature cracking.

Performance comparison for Pakistan’s high-temperature duty cycles

Descriptive title: Silicon carbide grades versus traditional refractories and steels in Pakistani kiln and furnace environments

| Property / Condition | R-SiC (Recrystallized SiC) | SSiC (Sintered SiC) | RBSiC (Reaction-Bonded SiC) | SiSiC (Silicon-Infiltrated SiC) | High Alumina (92–95%) | Heat-Resistant Steel (310/253MA) |

|---|---|---|---|---|---|---|

| Max service temperature (°C) | 1,650 | 1,700 | 1,450–1,500 | 1,600 | 1,600–1,700 (oxidizing) | 1,100–1,150 |

| Thermal shock resistance | Excellent (high porosity path) | Very good | Very good | Good–Very good | Good | Fair |

| Flexural strength at 20°C (MPa) | 40–60 | 350–450 | 220–300 | 280–350 | 40–80 | 25–35 |

| Oxidation/alkali resistance | Very good | Excellent | Very good | Very good | Good–Very good | Poor–Fair |

| Abrasion/erosion resistance | Excellent | Excellent | Excellent | Excellent | Good | Fair |

| Machinability (near-net shaping) | Moderate | Challenging | Good | Good | Good | Good |

| Typical use in Pakistan | Burner blocks, tiles | Inserts, seals, nozzles | Burner tiles/blocks | Structural tiles, wear plates | Burner tips/nozzles | Housings, mounts |

In Pakistani cement, RBSiC and SiSiC dominate burner block and tile applications due to their combination of high strength and manufacturability, while SSiC shines in inserts exposed to severe corrosion. High alumina tips remain common where swirl and port geometry favor ceramic-the-ceramic contact; however, pairing them with SiC structural elements significantly extends runtime. In contrast, heat-resistant steels distort, scale, and oxidize relatively quickly above 1,000°C, driving frequent tuning and shutdowns.

Real-world applications and success stories from Pakistan’s plants

At a cement plant in the Salt Range, frequent spalling around the burner quarl caused erratic flame anchoring and kiln inlet build-ups. Sicarbtech collaborated with the site to model gas velocities and clinker dust trajectories, recommending an RBSiC burner block set with SSiC inserts at the high-impingement edges. The plant reported a 22% increase in runtime between inspections and smoother NOx control due to stable flame geometry. Gas consumption normalized by 1.6% thanks to reduced excess air. “The change manifested less in dramatic headlines and more in a week-by-week absence of problems,” the production manager said during a post-implementation review (internal case note, 2025).

In a Karachi steel reheat furnace, scale abrasion was eroding metallic burner throats, skewing flame patterns and creating temperature non-uniformity of up to ±30°C across billets. Sicarbtech delivered SiSiC throat liners with a tailored surface finish to mitigate vortex shedding. Within two months, billet temperature uniformity tightened to ±12°C, enabling higher throughput without quality penalties. Maintenance intervals extended from 6 to 14 weeks, and gas usage per ton dropped by 1.2%.

A composite textile facility near Faisalabad sought to reduce singeing defects at high line speeds. Conventional refractory tips exhibited micro-chipping, requiring frequent alignment. Sicarbtech supplied high alumina burner tips mated to SSiC support sleeves to stabilize thermal gradients. The line achieved a 9% reduction in rework and 0.8% energy savings at the same production rate, attributed to consistent flame shape and reduced cold spots.

Technical advantages and implementation benefits with local compliance alignment

Beyond material properties on paper, implementation quality determines the realized benefit. Sicarbtech designs joint interfaces to avoid tensile stress risers, favoring compressive load paths under thermal expansion. Furthermore, graded interfaces between SiC and high alumina mitigate CTE mismatch. In highly dust-laden kilns, subtle chamfering and flow-directing lips reduce direct particle impingement on leading edges. Additionally, Sicarbtech’s finishing processes control surface roughness to balance heat transfer and ash accretion tendencies.

On compliance, documentation packages include mill test certificates, dimensional inspection reports, and process control records aligned with ISO 9001 quality management. For plants pursuing ISO 14001 and energy audits, stable burner geometry supports lower excess air and improved combustion efficiency, contributing to measurable KPIs. While Pakistan Standards and Quality Control Authority (PSQCA) does not publish detailed SiC component specifications, large industrial buyers typically benchmark to ASTM and ISO norms; Sicarbtech aligns material testing to ASTM C1161 (flexural strength), ASTM C373 (apparent porosity), and ASTM C704 (abrasion) where applicable, supplying traceable data and clear acceptance criteria to satisfy local procurement and insurance reviews.

An independent combustion specialist working across Lahore and Karachi observed, “Stable flame shape is a proxy for plant discipline; materials like SSiC and RBSiC allow operators to focus on process rather than firefighting” (technical webinar recap, 2025). That principle—process stability through materials engineering—sits at the heart of Sicarbtech’s Pakistan program.

Engineering selection guide: SiC and high-alumina burner components

Descriptive title: Burner system component selection for Pakistan’s cement, steel, and textile applications

| Application specifics | Recommended material set | Indicative service temp (°C) | Key advantage realized | Typical inspection interval |

|---|---|---|---|---|

| Cement kiln burner block with clinker dust | RBSiC block + SSiC insert at high impingement | 1,350–1,450 at block face | Erosion resistance and geometry retention | 8–12 weeks |

| Steel reheat furnace throat liner | SiSiC liner + SSiC wear ring | 1,100–1,250 | Reduced scale abrasion, stable flame | 10–14 weeks |

| Textile singeing nozzle support | SSiC sleeve + high alumina burner tip | 900–1,100 | Thermal stability, clean flame edge | 6–10 weeks |

| Petrochemical flare pilot shield | SSiC shield + R-SiC backing tile | 1,200–1,400 intermittent | Oxidation resistance, thermal shock | 12–16 weeks |

| Glass forehearth burner tile | SSiC tile + high alumina tip | 1,200–1,400 | Chemical resistance, dimensional stability | 8–12 weeks |

These pairings reflect common local operating envelopes and maintenance rhythms. Final selection is tuned during application engineering sessions that factor fuel composition, draft, and maintenance capability.

Custom manufacturing and technology transfer services: Sicarbtech’s in-depth advantage

Sicarbtech’s competitive edge lies in combining advanced R&D with pragmatic industrialization. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech runs iterative material and process experiments—powder size distributions, sintering profiles, infiltration parameters—to tailor R-SiC, SSiC, RBSiC, and SiSiC to the service environment. Proprietary manufacturing controls enable tight porosity distribution for R-SiC thermal shock performance and consistent free silicon content in SiSiC for high-temperature strength.

For Pakistan’s OEMs and large plant groups, Sicarbtech offers complete technology transfer packages. These include process know-how captured in SOPs, equipment specifications for debinding furnaces, sintering kilns, CNC machining and diamond grinding, metrology systems for flatness and concentricity, and spray/thermal cycle test rigs. Training programs cover material science fundamentals, quality control, and maintenance-friendly design. Factory establishment services begin with feasibility studies—market sizing, PKR-USD sensitivity analysis, utilities availability—and proceed through plant layout, environmental considerations, local staffing, and production line commissioning. Because quality is a function of discipline, not only machines, Sicarbtech embeds quality control systems from incoming powder characterization to final inspection, aligning with ISO 9001 and facilitating audits by multinational buyers.

Ongoing technical support is treated as a core product. Sicarbtech schedules routine process optimization reviews, correlating field wear patterns with microstructural data to refine subsequent batches. For customers scaling from pilot to volume, ramp plans and SPC dashboards ensure capability indices meet acceptance thresholds. The result for Pakistani partners is a turnkey pathway that compresses learning curves and de-risks localization. Compared to competitors offering only catalog sales, Sicarbtech’s cradle-to-commissioning approach consistently yields measurable outcomes—longer inspection intervals, fewer emergency orders, and lower energy normalization per ton of output.

Future market opportunities and 2025+ trends shaping adoption

By 2025, three forces will shape adoption of silicon carbide in Pakistan’s industrial sectors. First, energy efficiency will move from aspiration to contractual requirement as export-oriented buyers ask for verified energy intensity metrics, and as local utilities incentivize demand management. Component stability—ensured by SiC’s geometry retention—enables tighter combustion control and incremental gas savings that accumulate meaningfully over quarters.

Second, fuel flexibility will expand. Cement and steel plants will increase use of alternative fuels and variable gas blends. Materials that tolerate wider thermal and chemical excursions will become default, favoring SSiC and RBSiC in burner zones. Moreover, as digital combustion controls spread, the penalty for hardware drift grows; high-stability SiC minimizes that drift.

Third, localization will accelerate. Lead-time risk and currency volatility encourage partial local manufacturing or finishing. Sicarbtech’s technology transfer and factory establishment services align with this trend, enabling Pakistani OEMs to assemble, finish, and eventually produce select SiC components domestically, capturing value and improving responsiveness. “The plants that pair digital control with robust materials and local supply will outcompete on uptime and working capital,” concludes a Karachi-based industry analyst (market briefing, 2025).

Frequently asked questions

How do SSiC, RBSiC, R-SiC, and SiSiC differ in typical plant use?

While all are silicon carbide, SSiC provides the highest corrosion resistance and mechanical strength, making it ideal for inserts and seals. RBSiC offers a strong balance of strength and manufacturability for burner tiles and blocks. R-SiC excels in thermal shock due to its microstructure, suiting tiles near quench zones. SiSiC delivers high stiffness and wear resistance for structural liners and plates. Final selection depends on temperature, chemistry, and mechanical loading.

Can Sicarbtech integrate high alumina burner tips with SiC support structures?

Yes. Many Pakistani kilns use high alumina burner nozzles for flame shaping. Sicarbtech co-designs assemblies where high alumina tips mate to SSiC sleeves or RBSiC blocks, reducing thermal stress and edge chipping while preserving the desired swirl pattern and jet coherence.

What documentation is provided for compliance in Pakistan?

Sicarbtech supplies material certificates, dimensional reports, and test results aligned with ISO 9001 quality systems and common ASTM methods for ceramics. This documentation supports PSQCA-aligned procurement, customer audits, insurance reviews, and ISO 14001 energy and environmental reporting.

How does SiC improve energy efficiency in gas-fired equipment?

By holding geometry at temperature, SiC keeps burner orifices and throats within tolerance, stabilizing flame shape. This allows tighter excess air control and more consistent heat transfer, reducing gas usage by one to two percent in many cases, sometimes more when replacing distorted metallic parts.

What lead times should Pakistani plants expect?

For standard parts, four to six weeks is typical. Custom assemblies, larger tiles, or complex SSiC inserts may require six to eight weeks. With technology transfer or local finishing partners, lead times can be shortened and inventory buffers optimized.

How are components protected against alkali and clinker dust?

Material selection (often RBSiC with SSiC edges), geometry tweaks that deflect impingement, and surface finish control reduce wear. In severe zones, sacrificial shields or replaceable SSiC rings can be incorporated to localize wear and simplify maintenance.

Can Sicarbtech support OEM private-label (ODM) and custom (OEM) programs?

Absolutely. Sicarbtech runs OEM and ODM services, from co-engineering and tooling to branded packaging and documentation. CAD integration, FEA, and CFD support ensure form and function meet the OEM’s platform requirements.

What measurement units and standards are used?

Sicarbtech provides drawings and datasheets in SI units, consistent with Pakistan’s industrial practice, while referencing ASTM and ISO material test standards. Tolerances and thread specs can follow DIN/ISO or customer-specific requirements.

How do you ensure consistency between batches?

Statistical process control on powder properties, sintering curves, and dimensional checks, combined with destructive and non-destructive tests per batch, maintains consistency. Field feedback is looped into process adjustments to keep performance within tight bands.

Do you help with installation and commissioning?

Yes. For critical burner zones, Sicarbtech provides installation guides, on-site or remote supervision, and post-commissioning reviews. This includes torque specs, gasket selection, and warm-up procedures to minimize thermal shock.

Making the right choice for your operations

Choosing SiC is not about chasing exotic materials; it is about de-risking your core processes. If your burners, throats, and tiles define uptime, geometry stability at temperature should be your primary criterion. In cement and steel, pairing RBSiC or SiSiC structures with SSiC wear features will usually minimize total cost of ownership. In textile singeing and heat-setting, SSiC supports with high alumina tips maintain flame integrity and fabric quality. By engaging Sicarbtech early, you can co-design for your real fuel blends, thermal cycles, and maintenance practices, avoiding compromises that only show up after the third shutdown.

Get expert consultation and custom solutions

Sicarbtech — Silicon Carbide Solutions Expert — is ready to evaluate your kiln, furnace, or burner system and propose a silicon carbide solution tailored to Pakistan’s operating context. Share your process data, layout, and constraints with our engineering team at [email protected] or call +86 133 6536 0038. We will provide a rapid assessment, projected savings, and a staged implementation plan, and, where valuable, discuss OEM/ODM and technology transfer pathways to localize production and reduce currency and logistics risk.

Article metadata

- Last updated: 28 October 2025

- Next scheduled review: 28 January 2026

- Content owner: Sicarbtech Application Engineering, Weifang

- Contact: [email protected] | +86 133 6536 0038

- Freshness indicators: 2025 market outlook for Pakistan; new case learnings from cement and steel sites; updated guidance on OEM/ODM and technology transfer options tailored to local currency and logistics conditions.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.