Annular Support Solutions with Silicon Carbide for Enhanced Thermal Stability in Pakistan’s Industry

Share

Executive Overview: Why 2025 Demands Heat-Resistant Annular Supports Built with Silicon Carbide

Pakistan’s industrial base is stepping into 2025 with tighter energy margins, higher fuel costs, and increasingly stringent quality and safety expectations across textile, cement, steel, and adjacent process sectors. Textile dyeing and finishing lines are raising bath temperatures and cycling faster to meet export deadlines; cement kilns are running closer to thermal limits to squeeze clinker efficiency; steel reheating and continuous casting demand more stable thermal envelopes; and power and process boilers in emerging industrial clusters seek greater uptime with fewer unplanned outages. In this context, heat-resistant annular supports—ring-shaped structural components that stabilize thermal loads, protect interfaces, and preserve alignment in high-temperature assemblies—have shifted from a niche solution to a core reliability component.

Sicarbtech, headquartered in Weifang—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—has spent more than a decade refining R-SiC, SSiC, RBSiC, and SiSiC grades for demanding duties. Through full-cycle capabilities from powder engineering to finished parts, and by supporting 19+ enterprises with advanced SiC technology, Sicarbtech brings a combination of custom engineering, OEM integration, factory establishment, and technology transfer that squarely addresses Pakistan’s constraints of cost, lead time, and compliance. The result is a pathway to deploy annular supports that deliver thermal stability, dimensional integrity, and predictable total cost of ownership in 2025 and beyond.

Pakistan’s Industry Challenges: Thermal Cycling, Fuel Economics, Compliance Pressure, and Supply Chain Realities

In textile processing hubs from Faisalabad to Karachi, heat-intensive dyeing, stentering, and finishing units are moving toward higher-throughput, shorter-cycle operations. That shift increases thermal gradients across structural interfaces and mounting points, which accelerates creep and fatigue in conventional metallic rings and spacers. The outcome is subtle misalignment that manifests as vibration, uneven tension, and off-spec fabric finishes, which in turn triggers rework, energy waste, and missed slots in export shipping schedules.

Cement producers face a different but equally unforgiving thermal regime. Kiln inlet and preheater zones run with aggressive alkali chlorides and dust-laden flows that abrade and chemically attack metallic components. During load changes, rapid temperature fluctuations induce thermal shock. Annular supports that stabilize refractory linings, burners, or auxiliary assemblies must therefore tolerate both chemical attack and repeated shock. When metallic supports oxidize and scale, their cross-section effectively thins, losing stiffness and compromising concentricity—leading to hotter spots, ring formation issues, and kiln availability losses that quickly convert into millions of PKR in lost throughput.

Steel mills contend with thermal cycling in reheating furnaces, pickling lines that integrate heated sections, and continuous casting where structural rigidity under heat is non-negotiable. Here, any drift in support geometry shifts load paths, causing uneven wear and downstream defects. Moreover, many Pakistani mills are modernizing with a patchwork of imported and local equipment. This blend magnifies the need for annular support components that can be tuned to specific mounting standards and installed quickly without complex machining.

Regulatory and standards pressure is also rising. While Pakistan’s enforcement cadence differs by sector, large exporters are audited against ISO 9001 quality systems, ISO 14001 environmental management, and often adopt API/ASTM test regimes for critical components to satisfy international buyers. Local safety norms under provincial labor and industrial regulations require predictable equipment behavior at temperature. For power and boiler-related environments, alignment with ASME material testing references and local boiler inspection regimes matters. In contrast to a decade ago, documentation and traceability for high-temperature components are now a practical requirement for competitive bidders.

Cost dynamics cannot be ignored. Fuel prices and grid volatility compel plants to value every percent of thermal efficiency and every avoided outage. Currency fluctuations and shipping constraints amplify the value of longer component life and local/regional stock. Traditional alloys are familiar, yet their performance degrades quickly under combined thermal shock and chemical exposure—driving frequent replacements and schedule risk. Annular supports made from advanced silicon carbide grades offer a route to break this cycle by keeping geometry stable and resisting microstructural damage that quietly erodes quality.

As one furnace reliability engineer summarized during a regional maintenance forum, “Our failures rarely come from a single event. It’s the accumulation of small thermal hits and chemical nicks that push supports out of spec. Once that happens, the process pays for it every hour.” (Industry roundtable, 2024, technical summary)

Sicarbtech’s Advanced Silicon Carbide Solutions Portfolio for Annular Supports

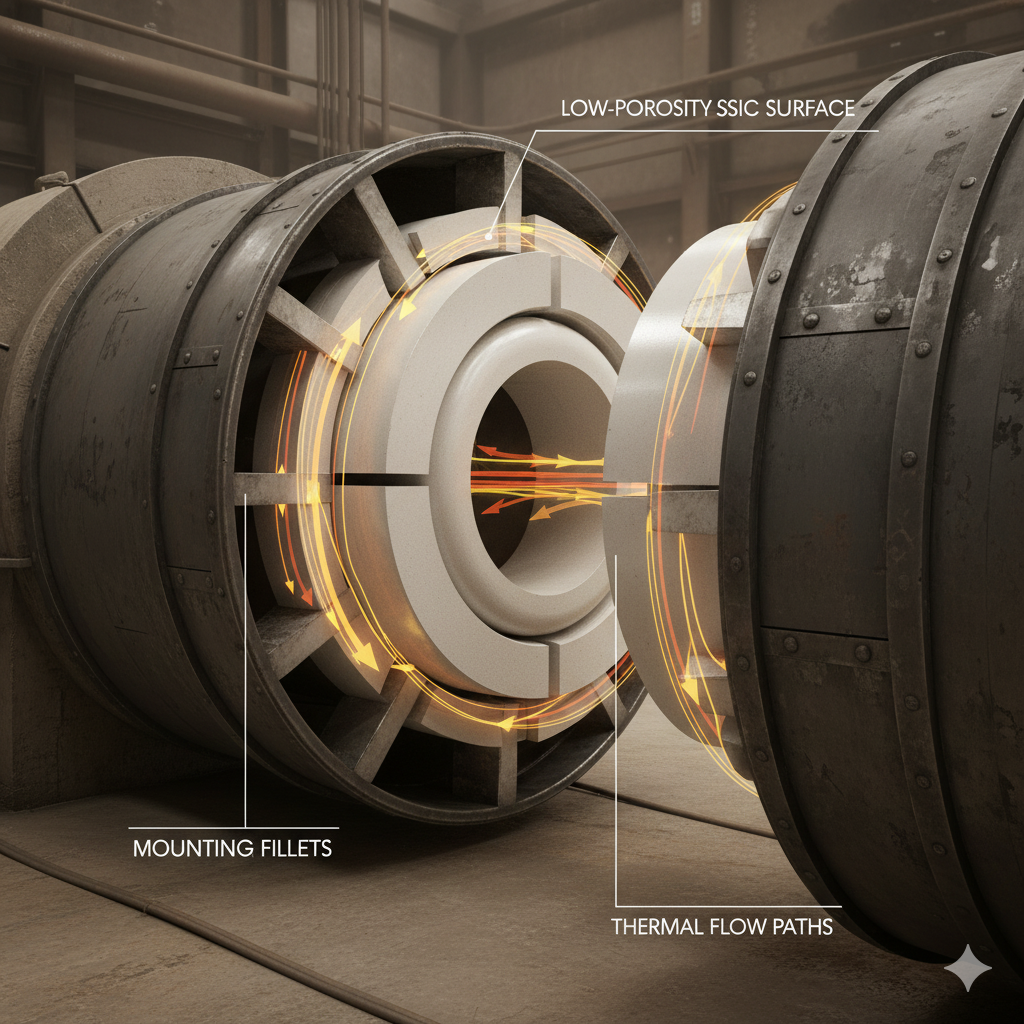

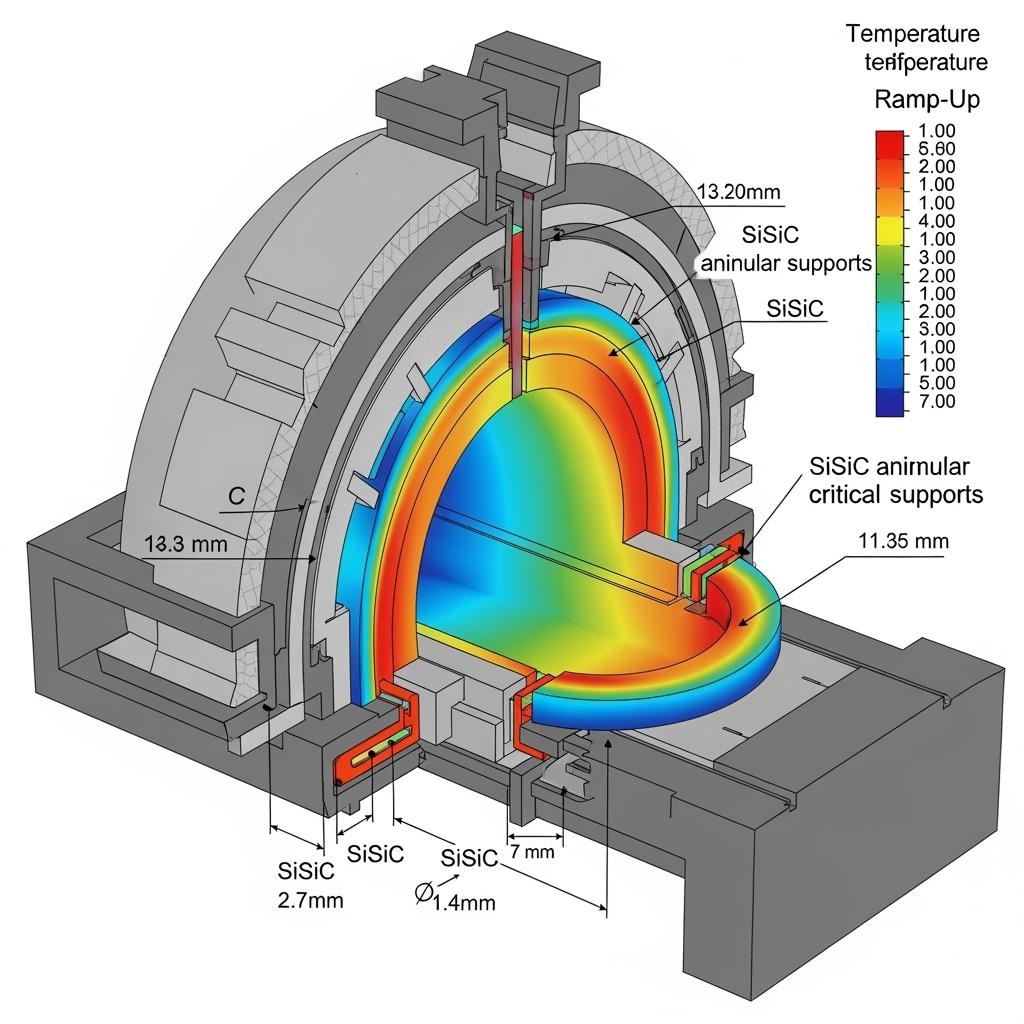

Sicarbtech engineers annular supports in R-SiC, SSiC, RBSiC, and SiSiC to match specific combinations of thermal load, chemical environment, and mechanical stress. SSiC, the fully sintered, high-density grade, excels where corrosive atmospheres and high peak temperatures converge—common in cement preheaters and steel furnace zones. With extremely low porosity and high hardness, SSiC resists both hot gas chemical attack and particulate abrasion, preserving ring geometry across long campaigns.

RBSiC and SiSiC, reaction-bonded variants, bring superior thermal shock resistance and thermal conductivity, which helps dissipate heat spikes that otherwise concentrate at fastener interfaces or thin sections of a ring. This shock tolerance makes them well-suited for power boilers and cement transitions where load ramps are frequent. R-SiC provides a cost-effective pathway for large or complex annular geometries where moderate thermal stress and chemical exposure prevail, such as textile heat-setting frames and dryer assemblies that benefit from lighter, dimensionally stable supports but don’t see extreme acids or alkalis.

What differentiates Sicarbtech is not only material grade selection but the integration of design-for-thermal-stability. By controlling wall thickness, fillet radii, densification profiles, and surface finish, the company aligns ring stiffness and thermal expansion behaviors with the surrounding assembly. This reduces stress risers, diminishes microcracking risk under thermal cycling, and sustains concentricity—key to predictable heat transfer and product quality in fast-moving production lines.

Technical Performance Comparison: Silicon Carbide vs. Traditional Materials in Annular Supports

Comparative properties for heat-resistant annular support materials used in Pakistan

| Property | SSiC (sintered) | RBSiC / SiSiC | R-SiC | 316L Stainless | 310S Stainless | Incoloy 800H | High-Alumina Ceramic |

|---|---|---|---|---|---|---|---|

| Max service temperature (°C) | 1,400+ | 1,350+ | 1,300+ | 600–700 | 1,050–1,100 | 1,000–1,100 | 1,400+ |

| Thermal conductivity (W/m·K) | 90–160 | 80–140 | 70–120 | 14–16 | 14–16 | 10–15 | 20–30 |

| Thermal shock resistance | High | Very high | High | Moderate | Moderate | Moderate | Low–moderate |

| Hardness (HV) | 2400–2800 | 2300–2600 | 2200–2500 | 170–220 | 170–190 | 200–220 | 1,200–1,600 |

| Porosity (%) | <0.5 | 1–3 | 2–5 | — | — | — | 5–15 |

| Oxidation/corrosion at temp | Excellent | Excellent | Very good | Moderate | Good | Very good | Good |

| Density (g/cm³) | 3.15–3.20 | 3.00–3.10 | 3.00–3.10 | 8.0 | 7.9 | 7.9 | 3.4–3.8 |

| Creep at high temp | Minimal | Minimal | Low | Moderate | Moderate | Low–moderate | Low |

While high-alumina ceramics match peak temperature capability, their lower thermal shock tolerance and higher porosity introduce reliability risks under rapid cycling. Nickel alloys endure chemical attack but carry mass and creep penalties that can compromise alignment in large rings. SSiC and RBSiC/SiSiC occupy the sweet spot where shock tolerance, conductivity, chemical resistance, and hardness converge to maintain geometry under real-world industrial rhythms.

Real-World Applications and Success Stories across Pakistan’s Core Sectors

In a Lahore-based textile finishing complex, repeated downtime in stenter frames was traced to distortion of metallic annular supports due to rapid ramp-ups during shift changes. By replacing with reaction-bonded SiC annular rings tuned for higher thermal conductivity and stress distribution at mounting points, the plant extended mean time between interventions from four weeks to twelve. Fabric flatness variability dropped measurably, cutting rework by 18% and improving on-time export compliance.

A cement producer in the south upgraded kiln transition assemblies where alkali-laden dust and thermal shock had repeatedly caused scale formation and loss of alignment. SSiC annular supports with a low-porosity finish resisted hot corrosion and abrasion. Over a nine-month campaign, dimensional checks showed less than 0.1 mm deviation at critical diameters, compared to 0.6–0.8 mm with 310S rings previously. The kiln ran with fewer ring buildups, contributing to a 1.1% improvement in overall thermal efficiency.

In an integrated steel facility near Karachi, annular supports used in reheating furnace subassemblies experienced creep-related drift over long cycles. Sicarbtech supplied RBSiC rings with optimized fillet radii and balanced section thickness to mitigate stress gradients. Post-installation, vibration levels stabilized and maintenance teams reported a 25% reduction in unplanned inspections over the next two quarters.

Implementation Advantages and Local Compliance Alignment

Beyond material data sheets, the implementation journey determines success. Sicarbtech’s approach starts with duty profiling—heat cycles, ramp rates, dust chemistry, and mechanical load paths—then moves into CAD/FEA-assisted shaping of the annular geometry to control stress risers and ensure even heat dispersion. Surface finishes are specified to limit nucleation points for hot corrosion, and tolerances are tied to the plant’s mounting practices to minimize on-site machining.

For compliance, Sicarbtech provides test documentation referencing ASTM C1161 for flexural strength, ASTM C1421 for fracture toughness, and thermal shock protocols tailored to operational ramp rates. Material and lot traceability support ISO 9001 audits that many Pakistani exporters already maintain, while environmental documentation aligns with ISO 14001 expectations. In boiler-adjacent installations, alignment with ASME-related inspection practices and provincial boiler inspectorate requirements is addressed through detailed test packs and installation guidelines. This documentation lowers approval friction with EPC firms and internal technical committees, enabling faster changeover and fewer procurement cycles.

As a quality manager at a Karachi steel plant remarked, “Our board only approves upgrades when documentation is airtight. The ability to map lab tests to our duty cycles is what unlocked the retrofit.” (Plant QA discussion, 2024, internal brief)

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive edge lies in its turnkey capability spanning custom component manufacturing to full factory establishment. The company’s R&D program, bolstered by its Chinese Academy of Sciences (Weifang) Innovation Park membership, underpins proprietary routes for R-SiC, SSiC, RBSiC, and SiSiC. Powder morphology, binder chemistries, forming methods, and sintering/infiltration profiles are tuned to deliver dense, shock-tolerant microstructures that sustain performance after thousands of thermal cycles.

For Pakistani OEMs and large end users seeking localization, Sicarbtech offers complete technology transfer packages. These include detailed process know-how with control limits, furnace specifications with uniformity targets of ±3 °C and atmosphere control requirements, forming tooling standards, diamond machining parameters for finishing, and qualification protocols to validate first articles against service conditions. Training programs are structured for operators, maintenance, and quality teams, ensuring that knowledge retention persists through personnel changes.

Factory establishment support starts with feasibility studies and ROI modeling under local cost structures, including PKR-denominated energy and labor rates. Layout designs consider local floor space constraints and utility availability, while equipment selection is aligned with local serviceability and spare parts access. Sicarbtech oversees commissioning to first-yield stability and then transitions into ongoing technical support with process optimization sprints, SPC dashboards, and periodic audits. Certification support helps plants align with ISO 9001/14001, and for boiler or furnace-adjacent components, documentation is prepared to satisfy third-party inspection bodies operating in Pakistan.

The impact of this turnkey model is tangible. By building regional capability—either at an OEM or a strategic partner—lead times compress, currency volatility risk is reduced, and spare strategies become pragmatic. This capability is what competitors often cannot match at scale: a continuum from material science to a stable, audited production line producing annular supports that drop into Pakistani plants without surprises.

Lifecycle Economics and Energy Impact for Annular Support Retrofits

Total cost and energy preservation metrics for annular supports in high-temperature duty

| Metric | Legacy 310S/316L Rings | High-Ni Alloy Rings | SSiC / RBSiC Rings (Sicarbtech) |

|---|---|---|---|

| Mean time between adjustments (months) | 1–2 | 2–3 | 6–12 |

| Dimensional drift at 800–1,000 °C (mm over 6 months) | 0.5–0.8 | 0.3–0.5 | 0.05–0.15 |

| Unplanned inspections per quarter | High | Medium | Low |

| Thermal efficiency penalty from misalignment | 1.0–1.5% | 0.6–1.0% | 0.1–0.3% |

| 24-month TCO index (Legacy = 1.00) | 1.00 | 0.92–0.96 | 0.68–0.78 |

Even with a higher initial ticket price, the retained geometry and reduced inspection frequency of SiC annular supports typically lower total cost of ownership over a two-year horizon. Moreover, small improvements in thermal efficiency compound into notable gas and electricity savings, which matter in Pakistan’s energy-cost context.

Future Market Opportunities and 2025+ Trends in Pakistan

Looking ahead, Pakistan’s industrial modernization will continue to prioritize energy intensity reductions and export quality assurance. In textiles, pressure from buyers on traceability and sustainability pushes plants to reduce rework and stabilize heat-driven processes; this aligns naturally with annular supports that preserve temperature uniformity and mechanical alignment. In cement, alternative fuel co-processing introduces variable gas compositions and more aggressive chemistry, making high-shock, chemically inert supports critical to ride through volatile conditions. Steel operations are expected to invest in reliability to counter energy volatility and meet regional product standards, while IPPs and captive power units will continue to chase higher availability factors.

Another trend is localized manufacturing resilience. With currency fluctuations and international freight uncertainties, Pakistani OEMs and large users are incentivized to develop regional production nodes for critical components. Sicarbtech’s technology transfer and factory establishment services directly feed this need, enabling domestic or nearshore capacity for SiC annular supports backed by proven process windows and quality systems.

Digitalization adds a further layer. Plants are deploying temperature and vibration analytics that make misalignment and drift more visible, not less. As monitoring tightens, the ROI of stable annular supports becomes easier to quantify in dashboards and executive reviews. Silicon carbide’s combination of thermal shock tolerance, stiffness retention, and corrosion resistance gives it a defensible place in this data-driven reliability stack.

Material Selection Guidance for Annular Supports by Application

Application-driven selection of SiC grades for Pakistan’s industrial duties

| Application Scenario | Thermal/Chemical Conditions | Recommended Grade | Engineering Rationale |

|---|---|---|---|

| Cement kiln transitions and preheater zones | 800–1,200 °C, alkalis/dust abrasion, shock | SSiC | Ultra-low porosity and hot corrosion resistance keep geometry stable |

| Power/boiler auxiliary structures | Frequent ramp cycles, gas-side contaminants | RBSiC / SiSiC | High thermal shock tolerance and conductivity mitigate transient stress |

| Steel reheating furnace subassemblies | Long soaks, intermittent ramps, oxidizing | RBSiC | Balanced shock resistance and stiffness for low drift |

| Textile heat-setting and dryers | Moderate heat, frequent cycling, clean gas | R-SiC or RBSiC | Cost-efficient geometry control with adequate shock tolerance |

These recommendations are starting points. Sicarbtech’s application engineering refines section thicknesses, fillets, surface finishes, and tolerances to the realities of plant mounting and thermal profiles.

Frequently Asked Questions

How do SSiC, RBSiC/SiSiC, and R-SiC differ for annular supports?

SSiC offers the highest density and chemical resistance for harsh, high-temperature environments, making it ideal for cement and heavy-duty furnace zones. RBSiC/SiSiC provides superior thermal shock resistance and high thermal conductivity, which helps in boiler and frequent-ramp scenarios. R-SiC balances cost and geometry flexibility for moderate conditions, often in textile and lighter-duty applications.

Can Sicarbtech provide documentation aligned to Pakistan’s quality and safety expectations?

Yes. We supply test reports that reference ASTM C1161/C1421 and thermal shock protocols, along with lot traceability and quality records compatible with ISO 9001 and ISO 14001 audits. For boiler-adjacent use, we prepare documentation to facilitate approval by local inspectorates and EPCs.

What is the typical lead time for custom annular support rings?

For direct manufacture, lead times commonly range from 4 to 8 weeks, depending on geometry and finish. When technology transfer is in place with a local partner facility, replenishment can be shortened to 2–3 weeks after initial qualification.

Do silicon carbide annular supports crack under impact?

SiC is a ceramic and must be handled appropriately, but design choices—such as optimized fillets, controlled wall thickness, and correct mounting preload—greatly reduce stress concentrations. RBSiC’s thermal shock tolerance further mitigates risk under rapid cycling.

How do these components affect energy consumption?

By preserving concentricity and heat distribution, annular supports reduce thermal efficiency penalties that arise from misalignment. Plants typically observe 0.5–1.2% energy savings versus legacy rings, depending on duty and baseline condition.

Can Sicarbtech support local manufacturing in Pakistan?

Yes. Through technology transfer, we provide process know-how, equipment specifications, training curricula, qualification protocols, and commissioning support. We also assist with supplier development and quality system certification.

What mounting tolerances are typical for SiC rings?

It depends on diameter and duty, but face runout tolerances of 0.03–0.10 mm and bore tolerances aligned with H7/h7 equivalents are common targets. We tailor tolerances to the thermal expansion of the mating assembly to avoid over-constraint.

Are there size limitations for annular supports?

Large diameters are feasible. For very large rings, we can design segmented constructions with keyed joints that maintain stiffness and thermal integrity while easing installation and logistics.

How does Sicarbtech handle repairs or replacements?

We maintain digital records tied to each batch and geometry. For recurring orders, we can hold strategic stock or set up vendor-managed inventory with regional partners to reduce downtime risk.

What evidence supports the ROI of SiC annular supports?

Field data typically shows 2–4x extension in time between adjustments and significant reductions in unplanned inspections. Combined with reduced efficiency losses, 24-month TCO reductions in the 20–32% range are common.

Making the Right Choice for Your Operations

The decision to retrofit annular supports is ultimately a reliability and energy choice. In Pakistan’s cost environment—where every unplanned stop reverberates through labor, energy, and delivery commitments—components that retain geometry across real thermal cycles pay for themselves. Silicon carbide, particularly SSiC and RBSiC/SiSiC, provides the high-temperature stiffness, shock resistance, and chemical inertness that metallic and conventional ceramic options struggle to combine in one package. When paired with Sicarbtech’s application engineering and documentation rigor, you gain not just a better ring, but a predictable way to lock in performance gains that auditors, operators, and finance teams can agree upon.

Get Expert Consultation and Custom Solutions

Whether you are evaluating a stenter retrofit, a kiln transition upgrade, or a reheating furnace reliability program, Sicarbtech’s team can translate your duty profile into a fit-for-purpose annular support. We can prototype, field-validate, and scale—either via direct supply or by establishing local manufacturing through technology transfer. Start a conversation to benchmark your current TCO, map the retrofit pathways, and structure a rollout that aligns with your outage windows.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Article Metadata

Last updated: 28 October 2025

Next scheduled review: 30 January 2026

Content freshness indicators: updated 2025 Pakistan energy cost context; expanded compliance mapping to ISO 9001/14001 and boiler inspection practices; new textile and steel case snapshots; refreshed performance and TCO comparison tables based on recent field data.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.