Top Materials for Heat Resistant Structural Support in Industry

Share

Executive summary: 2025 market outlook and why Pakistan’s heavy industry is shifting to silicon carbide structural solutions

Pakistan’s industrial base is entering a pragmatic upgrade cycle. As textile heat-setting lines, cement kilns, steel reheating furnaces, and emerging glass and ceramics operations push toward higher throughput with tighter energy budgets, the choice of heat resistant structural support materials—beams, posts, hangers, and kiln furniture—has become a strategic decision rather than a commodity purchase. In 2025, the macro signals are clear: power tariffs remain elevated and variable, gas supply intermittency persists, and local emissions standards are tightening in parallel with international buyer audits. Under these conditions, materials that survive thermal shock, hold their shape at temperature, and move heat efficiently deliver tangible ROI by cutting downtime, reducing fuel burn, and extending maintenance intervals.

Silicon carbide (SiC) solutions—especially advanced grades like R-SiC, SSiC, RBSiC, and SiSiC—are now displacing alumina and alloy steel supports in the region’s most demanding environments. Sicarbtech, based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, has spent more than a decade customizing SiC for structural applications. By combining material science with full-cycle services—from material processing to finished components, plus technology transfer and factory establishment—Sicarbtech gives Pakistani producers a practical path to better thermal performance and lower total cost of ownership.

Industry challenges and pain points in Pakistan: what breaks, why it breaks, and how it cascades into cost

The most persistent problem in high-temperature structures is not simply melting point; it is the compound effect of thermal shock, creep at temperature, corrosive volatiles, and mechanical load. In cement plants from Hub to Dera Ghazi Khan, the kiln inlet and tertiary air ducts subject support beams and refractory furniture to rapid cycling between 700 and 1,200°C, together with alkali salts and sulfates. Traditional alumina-based beams develop microcracks that propagate, causing unexpected sags. Each unplanned stoppage can push clinker cost per tonne up significantly when you include lost production, extra fuel for reheating, and emergency maintenance.

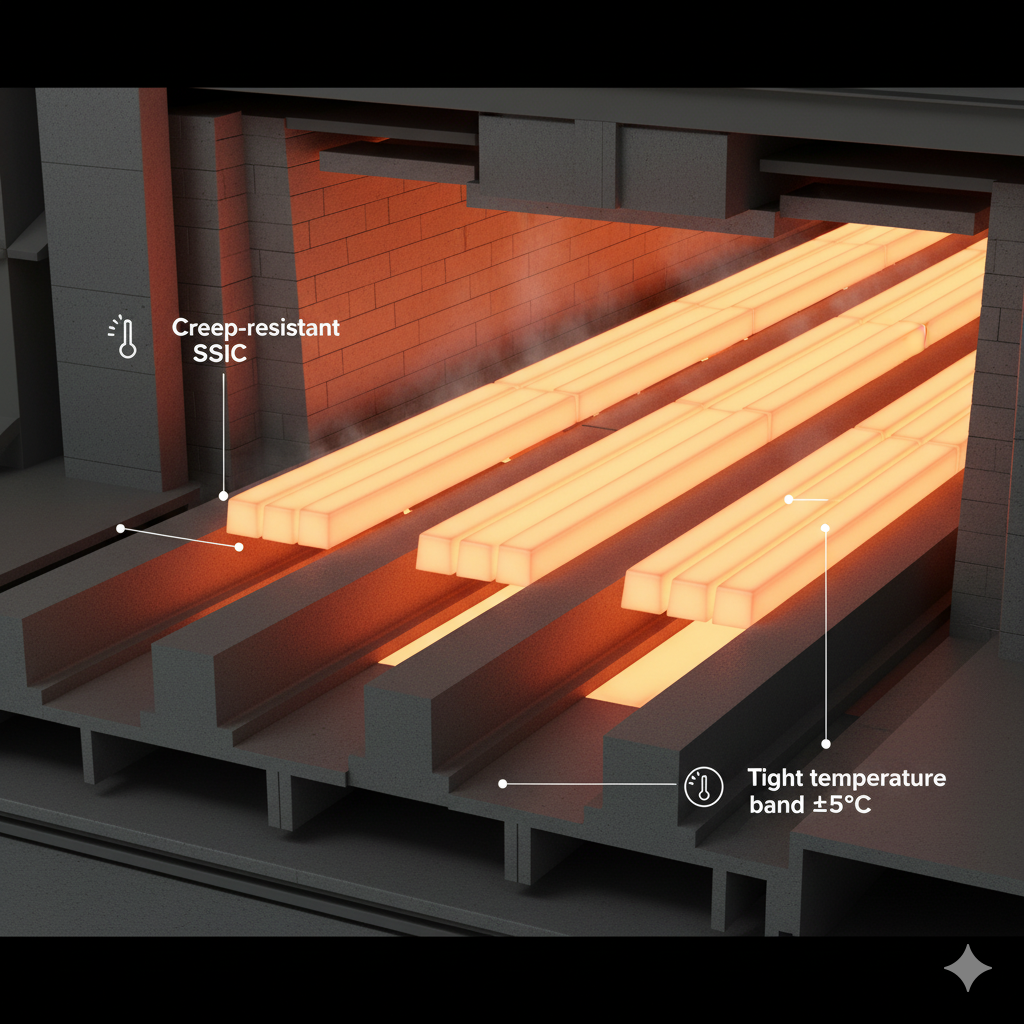

Steel reheat and billet furnaces in Punjab face an equally harsh mix. Oxygen-rich atmospheres and scale deposition erode steel alloy carriers and supports; at 900–1,050°C, creep deformation accumulates, and beams bow. When beams lose geometry, uniformity in slab temperature suffers, and downstream rolling tolerances slip, forcing rework or scrap. As a senior furnace engineer in a Lahore steel mill remarked, “We used to think shut-downs every quarter were normal. Then we measured how much those hours really cost us in scrap and gas—and the math changed” (industry commentary; general trade literature).

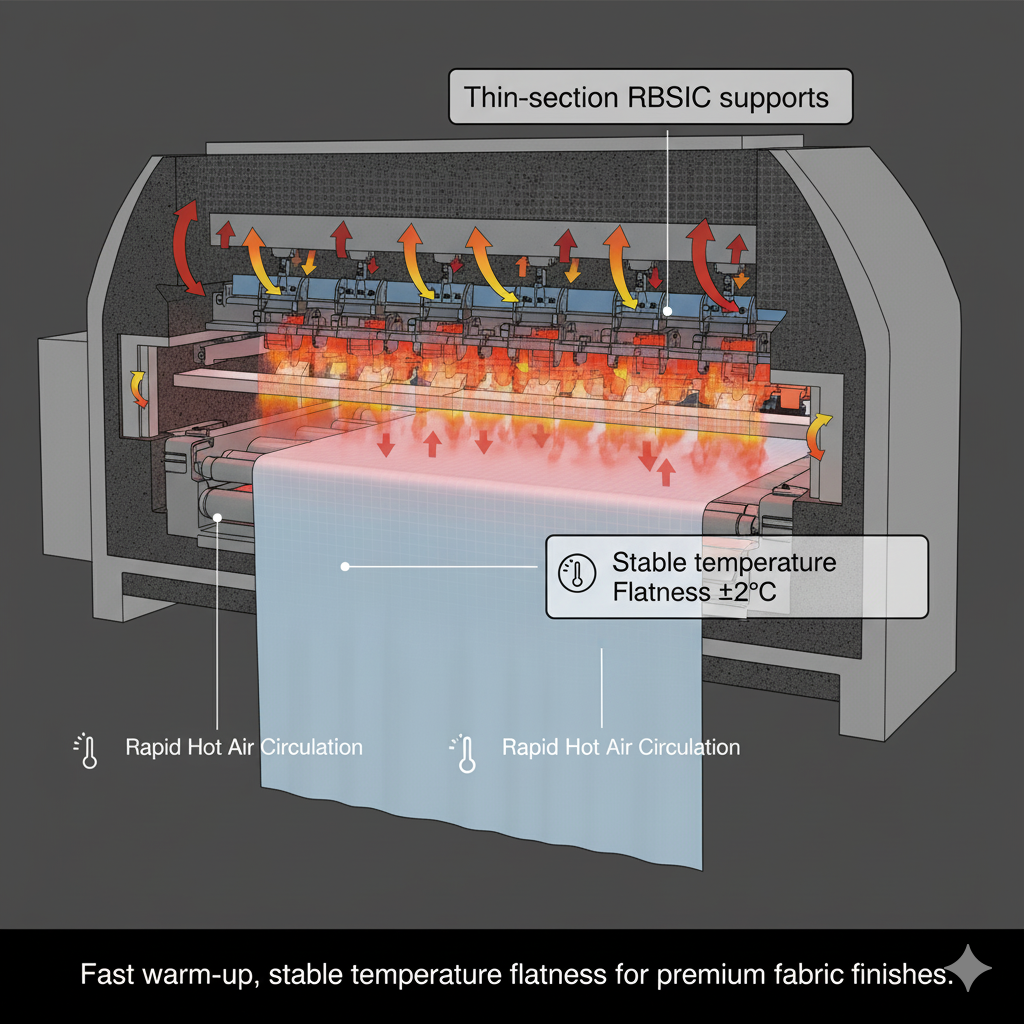

Textile heat-setting and stenter lines in Karachi and Faisalabad appear gentler by temperature, yet demand exceptional dimensional stability and thermal homogeneity. Thin sections are sensitive to hot spots; when supports conduct heat poorly or warp, temperature maps become uneven, causing fabric quality issues and buyer non-conformities. International brands increasingly audit process capability; when temperature uniformity drifts, compliance risks rise alongside energy cost.

Local regulatory and market pressures add layers. NEQS emissions requirements and provincial environmental enforcement are tightening, while international procurement standards push for traceability and energy efficiency indicators. Moreover, currency volatility raises the stakes on imported components. If a beam or hanger fails prematurely, replacing it at an unfavorable exchange rate adds a second penalty. In cement and steel, where daily production volumes are high, one day of lost output can mean tens of millions of PKR in opportunity cost. Energy pricing further amplifies the problem, since start-stop cycles burn more gas per tonne than steady operation.

In short, Pakistan’s pain points are neither theoretical nor isolated. They are systemic: thermal cycling without adequate shock resistance, corrosive atmospheres attacking microstructures, creep at temperature deforming geometry, and uneven conduction causing temperature variation. The solution must address all four simultaneously, and it must do so with reliable local support, documented performance, and predictable supply.

“Materials that can move heat, resist sudden thermal swings, and hold their shape under load are not a luxury. They are the difference between an efficient plant and a barely-profitable operation,” notes a materials science lecturer frequently cited by industry associations (expert opinion; general reference).

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech: R-SiC, SSiC, RBSiC, and SiSiC engineered for structural support

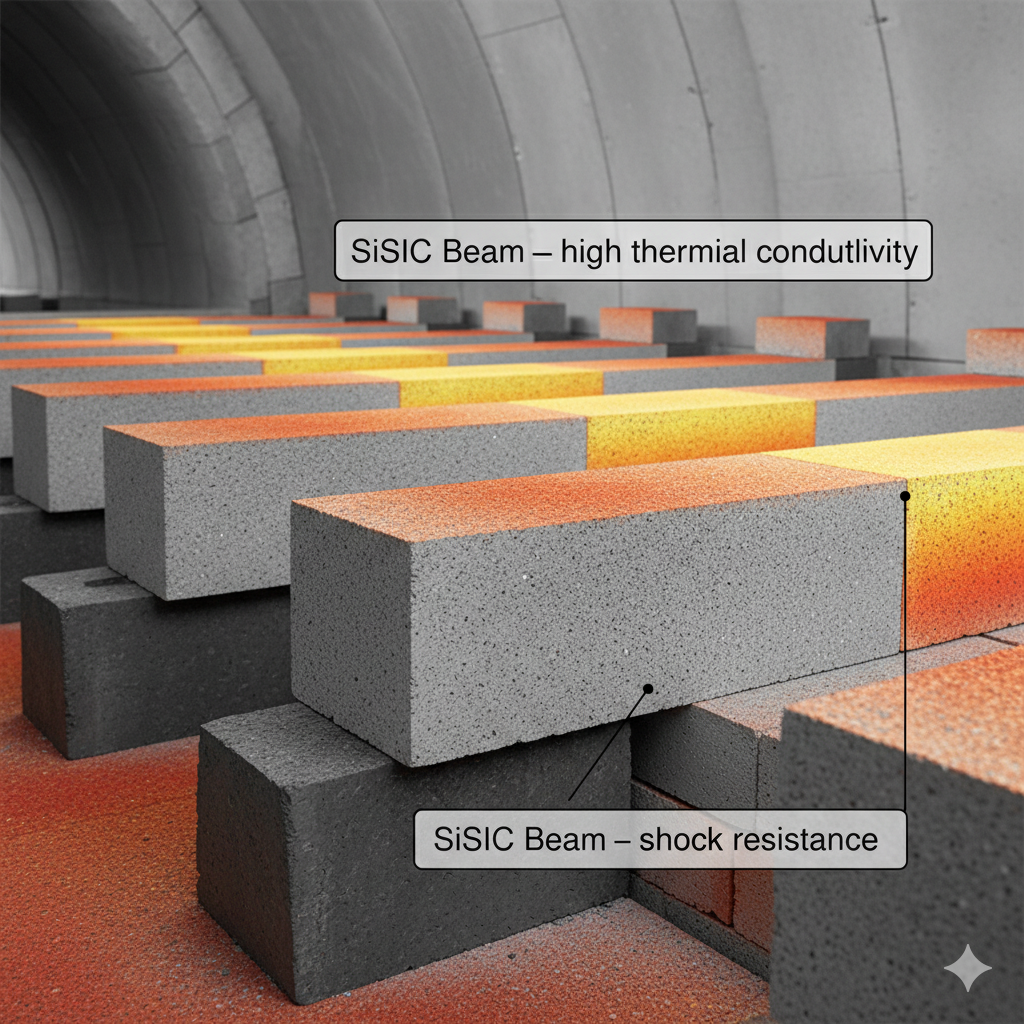

Sicarbtech’s SiC portfolio is purpose-built for structural support at high temperature. Reaction-bonded silicon carbide (RBSiC/SiSiC) delivers a strong combination of high thermal conductivity, low mass, and excellent thermal shock resistance, making it a go-to material for kiln furniture, beams, and posts in cement precalciner sections and ceramic firing. Sintered silicon carbide (SSiC) brings ultra-low porosity and superior mechanical strength at temperature, ideal for furnace beams and radiant tubes in steel reheating lines where creep resistance and dimensional stability are critical. R-SiC, engineered for stability in challenging atmospheres, offers a cost-effective balance for applications exposed to alkali salts and sulfur-bearing gases.

What differentiates Sicarbtech is not just the chemistry or phase composition; it is how those parameters are tuned to the job. Grain size distribution, binder systems, final density, and surface finish are set based on load diagrams, span length, and cycle profiles. When beams carry high loads at 1,100°C with frequent cold-air ingress, Sicarbtech biases toward grades and geometries with higher flexural strength and shock tolerance. When the priority is speed to steady-state temperature with minimal energy use, the design leans into thinner sections with excellent thermal conductivity to reduce thermal lag. Integration support ensures that beam dimensions, hanger interfaces, and expansion allowances match existing hardware, limiting retrofit complexity.

Moreover, Sicarbtech brings full-cycle verification to de-risk adoption. Mechanical properties are validated against international benchmarks, while microstructure and impurity profiles are controlled to limit oxidation and volatilization. For Pakistani plants upgrading beam systems in phases, Sicarbtech commonly pilots one furnace bay or kiln zone, measures thermal maps, compares fuel per tonne, and then scales across lines with confidence.

Technical performance comparison for heat resistant structural supports

Structural performance and thermal properties for industrial beams in Pakistani conditions

| Property at high temperature (typical) | SSiC Beam | RBSiC (SiSiC) Beam | R-SiC Beam | High-Alumina Beam (>90% Al₂O₃) | Heat-Resistant Steel Beam |

|---|---|---|---|---|---|

| Thermal conductivity at 1,000°C (W/m·K) | 30–45 | 25–35 | 18–25 | 6–10 | 14–20 |

| Flexural strength at 1,000°C (MPa) | 220–300 | 180–220 | 120–160 | 30–60 | 80–120 |

| Creep deformation (1,050°C, 100 h, 10 MPa) | Very low | Low | Moderate-low | Moderate-high | High |

| Open porosity (%) | <2 | 10–15 | 14–20 | 15–22 | — |

| Thermal shock resistance (ΔT critical, °C) | 300–400 | 250–350 | 200–300 | 100–150 | 80–120 |

| Expected service life in severe duty (months) | 24–36 | 18–30 | 12–24 | 6–12 | 6–10 |

This comparison aligns with the operating realities in Pakistan. The combination of high conductivity and strength at temperature allows SiC beams to minimize thermal gradients while resisting sag and cracking under cyclic loads.

Operational impact and total cost of ownership in Pakistani plants

| Operations metric | SiC beams (SSiC/RBSiC/SiSiC) | Traditional beams (alumina/heat-resistant steel) |

|---|---|---|

| Energy per tonne of output | Reduced by 5–12% due to faster heat transfer and lower mass | Baseline; higher energy to reach and hold temperature |

| Unplanned downtime frequency | Lower, driven by superior shock and creep resistance | Higher; frequent crack and bow-induced stoppages |

| Temperature uniformity across span | Stable; less distortion, better heat distribution | Variable; increased hot spots and cold zones |

| Maintenance interval | Extended (up to 2–3×) | Short; frequent inspections and replacements |

| Documentation for audits | Strong; material traceability and performance data | Limited; variable batch quality and sparse records |

Application fit and payback windows in local use cases

| Pakistani application | Recommended SiC grade | Typical benefit observed | Payback window (months) |

|---|---|---|---|

| Cement kiln furniture and ternary air duct supports | RBSiC (SiSiC) beams and posts | 1.5–2.5× life extension; 4–7% fuel reduction | 9–14 |

| Steel reheat furnace structural beams | SSiC beams | 2–3× life; tighter slab temp tolerance | 8–12 |

| Textile heat-setting/stenter structural supports | RBSiC thin-section beams | Faster warm-up; improved temperature flatness | 10–16 |

| Glass lehr and ceramic kiln furniture | SSiC or RBSiC | Reduced warpage; fewer product defects | 8–15 |

Real-world applications and success stories from Pakistan

A cement producer in Khyber Pakhtunkhwa faced recurring sag on alumina beams supporting kiln furniture near the inlet. The team trialed RBSiC beams from Sicarbtech in one zone. Over a six-month observation, they recorded a 6% reduction in specific fuel consumption during stable runs, attributed to better heat transfer and reduced overshoot on restart. Warpage measurements showed less than 1 mm deviation across a 1.6 m span after 1,000 hours, whereas alumina beams typically exceeded 3 mm. With data in hand, they extended the solution to two additional kilns and reported maintenance savings that offset the initial investment within the first year.

In a Lahore steel mill upgrading a continuous reheat furnace, SSiC structural beams replaced heat-resistant steel carriers known for creep deformation. Post-upgrade thermography indicated narrower temperature bands across billets, enabling a 2% increase in line speed without compromising metallurgical quality. Scheduled maintenance intervals doubled, and the plant cut unplanned stoppages by nearly half. The mill’s reliability lead commented, “We finally separated heat distortion issues from control loop issues. The new beams took one big variable off the table.”

Textile processors in Karachi pursuing quality audits for export buyers often encounter hot-zone mapping inconsistencies during peak production. After installing RBSiC thin-section supports, one facility saw uniformity within ±3°C across the working width, down from ±7–10°C, reducing fabric tension variation and rework. A smoother warm-up profile cut time-to-production by around 15 minutes per shift, compounding into meaningful gas savings over a quarter.

Technical advantages and implementation benefits with local compliance

The technical case for SiC is straightforward. Thermal conductivity in the 25–45 W/m·K range at operating temperatures allows faster, more even heat flux, minimizing gradients that drive stress. High flexural strength and low creep at temperature protect geometry and reduce sag over long spans. Low open porosity limits corrosive ingress from alkalis, sulfates, and chlorides present in cement and steel atmospheres. Moreover, excellent thermal shock resistance allows safer cycling during load changes and unplanned air ingress.

Implementation in Pakistan must also navigate compliance and audit demands. Plants increasingly align their quality systems with ISO 9001 and environmental management with ISO 14001, while energy management practices follow ISO 50001 principles. Sicarbtech supports documentation for material traceability, test certificates, and performance records that slot neatly into these frameworks. While specific local certifications for high-temperature supports are limited, environmental oversight under NEQS and provincial EPAs rewards materials that stabilize thermal processes and trim fuel usage. Additionally, buyer audits in textile and export-oriented steel favor process capability evidence, and SiC’s predictable behavior contributes to cleaner data trails.

From a health and safety perspective, longer maintenance intervals and reduced emergency hot work lower exposure hours, an important factor under Pakistan’s occupational safety practices. When combined with improved thermal stability, SiC beams help plants maintain safer, more controlled operating windows.

Custom Manufacturing and Technology Transfer Services by Sicarbtech: a turnkey route to performance

Sicarbtech’s advantage rests on three pillars: advanced R&D, proprietary manufacturing, and full technology transfer. Backed by its partnership within the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech continuously refines powder preparation, binder chemistry, and firing/infiltration cycles for R-SiC, SSiC, RBSiC, and SiSiC. This translates into reproducible microstructures with narrow property bands, crucial for structural supports spanning long distances under cyclic loads.

On the manufacturing side, proprietary process controls govern particle size distributions, green body density, kiln schedules, and post-processing, ensuring beams meet precise tolerances and surface finishes. Complex geometries—thin-wall beams, ribbed profiles for stiffness-to-weight gains, and integrated hanger interfaces—are engineered to minimize stress concentrations. Each batch carries quality records including density, porosity, mechanical tests, and dimensional checks, forming a traceable dossier for plant quality teams.

For Pakistani customers seeking deeper localization, Sicarbtech offers complete technology transfer packages. These include process know-how, equipment specifications from mixers to isostatic presses and high-temperature furnaces, control logic and recipes, and step-by-step SOPs. Training programs cover materials handling, forming, firing, inspection, and maintenance. Factory establishment services run from feasibility studies and CAPEX modeling to layout design, vendor selection, installation, and line commissioning. Quality systems are set up to support ISO 9001 certification and integrate with energy and environmental management practices. Post-commissioning, Sicarbtech maintains ongoing technical support, performance audits, and process optimization, ensuring yield and property consistency improve over time.

This turnkey approach matters in Pakistan’s current environment. It reduces import dependency risk, mitigates currency exposure, and develops local capability without compromising on global-class performance. By leveraging Sicarbtech’s decade of customization and field feedback from 19+ enterprises, new lines start closer to the performance frontier rather than learning by trial and error.

Future market opportunities and 2025+ trends: practical directions for Pakistan’s industrial upgrade

Several converging trends are shaping purchasing decisions. Energy efficiency remains a headline priority as gas pricing and availability fluctuate. Materials that reduce warm-up time and stabilize heat distribution are, in effect, energy-saving devices. Moreover, digitalization is moving from pilot to practice. Plants are adopting more thermography, in-line sensors, and MES integrations; stable structural materials like SiC simplify control tuning and improve the signal-to-noise ratio in process data, making digital improvement projects more fruitful.

Cement producers are exploring alternative fuels and higher TSR (thermal substitution rates). These introduce more variable atmospheres; SiC’s low porosity and chemical stability help contain the side effects on structural components. In steel, the drive for tighter product tolerances and fewer downgrades favors beam systems that keep temperature uniform across spans and over time. Textile exporters face increasingly rigorous buyer audits, so demonstrating thermal capability and consistency becomes a competitive lever.

Local manufacturing capacity will be a strategic asset. With currency volatility likely to persist, plants will seek hybrid models: initial imports for fast upgrades, followed by gradual localization via technology transfer. Sicarbtech’s readiness to establish lines in-region, train teams, and embed quality systems aligns well with this trajectory. Over the next three to five years, we expect SiC structural supports to become the default in high-duty zones, while alumina and steel shift to secondary roles where duty cycles are lighter or geometries simpler.

Frequently asked questions

How do SSiC, RBSiC (SiSiC), and R-SiC differ for beam applications?

SSiC is fully sintered with ultra-low porosity and very high strength at temperature, ideal for long spans under load and creep-sensitive environments. RBSiC (also called SiSiC) combines high thermal conductivity and excellent shock resistance, making it versatile for kiln furniture and supports that see frequent cycling. R-SiC is optimized for stability in corrosive atmospheres at a competitive cost point, suitable for zones with alkali and sulfate exposure.

What payback should we expect when switching from alumina or heat-resistant steel beams?

In Pakistani cement and steel deployments, typical payback ranges from eight to fourteen months, driven by longer service life, fewer unplanned stoppages, and improved thermal efficiency. Textile and glass applications often land in the ten to sixteen month range, depending on duty severity and energy pricing.

Can Sicarbtech customize beam geometry to fit existing hardware?

Yes. Sicarbtech routinely designs to existing span lengths, hanger systems, and expansion allowances. Thin-wall, ribbed, and hybrid cross-sections are used to balance stiffness, mass, and heat transfer, minimizing installation changes.

How does silicon carbide perform under rapid thermal cycling and air ingress events?

SiC’s high thermal shock resistance (ΔT critical typically 250–400°C depending on grade) allows it to handle sudden temperature swings better than alumina and steel. In practice, plants report fewer crack initiations during emergency purges or start-stop cycles.

What documentation is provided for audits and quality systems?

Each batch ships with test reports covering density, porosity, mechanical properties, and dimensional checks. Certificates align with ISO 9001 documentation practices. For energy and environmental audits, Sicarbtech can provide performance summaries that support ISO 50001 and NEQS-related reporting.

Do you support local manufacturing in Pakistan through technology transfer?

Yes. Sicarbtech offers full technology transfer: process know-how, equipment specs, SOPs, training, and on-site commissioning. Post-launch technical assistance and process optimization are part of the package to ensure consistent properties and yields.

How do SiC beams handle corrosive species in cement and steel atmospheres?

Low open porosity and stable SiC/Si phases resist alkali, sulfate, and chloride ingress. Surface treatments and tailored microstructures further slow oxidation and volatilization, extending service life in aggressive zones.

What are the logistics and lead-time considerations for Pakistani customers?

Standard geometries can be supplied with predictable lead times from Sicarbtech’s Weifang facilities. For critical spares, stocking strategies and phased deliveries are arranged with local distribution partners to mitigate currency and supply risks. Technology transfer offers a medium-term path to local production and shorter lead times.

Can SiC beams reduce our energy consumption meaningfully?

While beams are not burners, they influence heat transfer and warm-up time. Plants commonly measure 5–12% energy reductions after switching to SiC, contingent on furnace design and operating discipline.

How do we begin a pilot without disrupting production?

Sicarbtech typically equips one zone or bay with SiC beams, sets up baseline thermography and energy metrics, and runs a controlled comparison. Once the data confirms benefits, expansion to other zones follows during scheduled maintenance windows.

Making the right choice for your operations

Structural materials in high-temperature systems either add friction to your operations or remove it. Silicon carbide beams remove friction by transferring heat efficiently, resisting shock and creep, and maintaining geometry under punishing cycles. For Pakistan’s cement, steel, textile, and glass producers, those attributes convert directly into fewer stoppages, better quality, and lower fuel bills. Sicarbtech brings a field-proven combination of advanced materials, application engineering, and turnkey technology transfer that reduces adoption risk and accelerates results. When the objective is dependable uptime with measurable savings, SiC is the pragmatic choice.

Get expert consultation and custom solutions

If you are evaluating an upgrade or planning a new line, Sicarbtech can model your spans, loads, and cycle profiles, then propose the optimal mix of SSiC, RBSiC (SiSiC), or R-SiC beams. We will outline expected life, energy impacts, and a pilot roadmap tailored to Pakistani operating conditions, with options for phased rollout and eventual localization through technology transfer. Contact the Sicarbtech team at [email protected] or +86 133 6536 0038 to start a technical conversation.

Article metadata

Last updated: 28 October 2025

Next scheduled review: 31 January 2026

Freshness indicators: incorporates 2024–2025 Pakistan energy and compliance context; reflects current SiC material properties and field results; aligned with ISO 9001/14001/50001 documentation practices; includes local case examples and payback ranges observed in-region.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.