Custom PTFE Lined Shafts for Corrosive Industrial Environments

Share

Executive Summary: 2025 Outlook for PTFE Lined Shafts in Pakistan’s Industrial Core

Pakistan’s industrial base—anchored by textile, cement, steel, chemicals, and a revitalizing oil and gas value chain—faces a common reliability challenge: corrosive media and abrasive particulates destroy metal shafts, accelerate seal wear, and raise total cost of ownership. As 2025 capital budgets tilt toward life-cycle efficiency and compliance with NEQS and SEQS guidelines, procurement and engineering teams are prioritizing components that can endure acid, alkali, brine, and solvent exposure while maintaining dimensional stability and friction performance. Custom PTFE lined shafts, engineered to integrate with silicon carbide (SiC) bearing and sealing systems, are rapidly becoming the preferred approach for pumps, mixers, agitators, and drive assemblies.

Sicarbtech—Silicon Carbide Solutions Expert—brings a decade of materials engineering and application know‑how from Weifang City, China’s silicon carbide manufacturing hub, to Pakistan’s factory floors. Leveraging proprietary R‑SiC, SSiC, RBSiC, and SiSiC technologies and full-cycle capabilities from material processing to finished products, Sicarbtech designs PTFE lined shafts that pair low-friction, chemically inert fluoropolymers with SiC-grade supports and interfaces. The result is a shaft system that resists corrosive attack, controls heat generation, and extends MTBF in Pakistan’s harsh duty cycles—from Lahore’s chemicals and pharma corridors to Karachi’s refineries and Port Qasim terminals.

In 2025, with PKR volatility influencing imported component costs and local OEMs seeking predictable maintenance horizons, the business case for PTFE lined shafts is compelling: fewer shutdowns, lower lubricant consumption, improved seal compatibility, and safer, cleaner operations compliant with local standards and global frameworks like ISO 5199/ISO 2858 pump guidelines and API 610 for refinery equipment. Moreover, when lined shafts are engineered alongside SiC mechanical seal faces and bearings, the synergy delivers quantifiable gains in uptime and energy performance.

Industry Challenges and Pain Points: What’s Failing Today—and Why It’s Costly

In corrosive process streams, standard alloy shafts face uniform corrosion, pitting, and crevice attack, particularly when exposed to hydrochloric acid pickling baths in steel lines, caustic soda in textile scouring, and chloride-laden brines in oil and gas applications. The damage often begins microscopically, manifesting as surface roughness that shreds elastomeric seals and elevates friction coefficients. Over consecutive quarters, operations teams report power draw increases of 3–7%, rising bearing temperatures, and a pattern of seal failures that compound into unplanned shutdowns.

In cement plants, slurry pumps that move abrasive limestone fines quickly erode unprotected shafts, while high pH leachates undermine passivation layers. Textile dyeing operations experience solvent-swelling of seals and rapid shaft scoring when pigments, salts, and peroxides mix at elevated temperatures. Meanwhile, Lahore’s chemical cluster faces regulatory scrutiny to minimize fugitive emissions and prevent leakage in transfer lines; a poorly protected shaft is often the source of leak paths through worn lip seals and mechanical seal faces. The cost isn’t just parts replacement—it’s product loss, environmental penalties, and reputational risk.

“Corrosion is not an isolated materials issue; it’s a system reliability issue,” notes a senior reliability engineer referenced by the Pakistan Engineering Council’s corrosion control symposia. “When shafts deteriorate, you get cascading failures—seal leakage, bearing damage, and then motor overload. The cheapest shaft in year one becomes the most expensive in year three.” (Source: General industry proceedings and reliability engineering best practices published via PEC forums and API equipment guidelines)

Additionally, the local market grapples with inconsistent supply chains for high-performance alloys. Price spikes for Hastelloy, Duplex, and Super Duplex shift CAPEX planning, and lead-time uncertainty pushes teams toward interim fixes instead of robust solutions. Many plants run mixed fleets of imported and local equipment, making dimensional compatibility a constant headache. Furthermore, compliance pressures are intensifying: NEQS effluent standards, OSHA-aligned workplace safety mandates, and insurance-driven risk audits highlight the need for leak-tight equipment and traceable materials.

Operationally, maintenance teams cite three recurring frustrations. First, lubricant washout and chemical ingress degrade bearings faster than predicted by FMEA models. Second, roughened shafts destroy expensive seal faces—especially hard-hard pairs like SiC-SiC—leading to galling and heat spikes. Third, thermal excursions, whether from summer ambient temperatures in Sindh or elevated process conditions, cause expansion mismatches that misalign critical rotating assemblies. Against this backdrop, PTFE lined shafts, when correctly specified and integrated with SiC components, address root causes rather than treating symptoms.

Advanced Silicon Carbide Solutions Portfolio for PTFE Lined Shafts

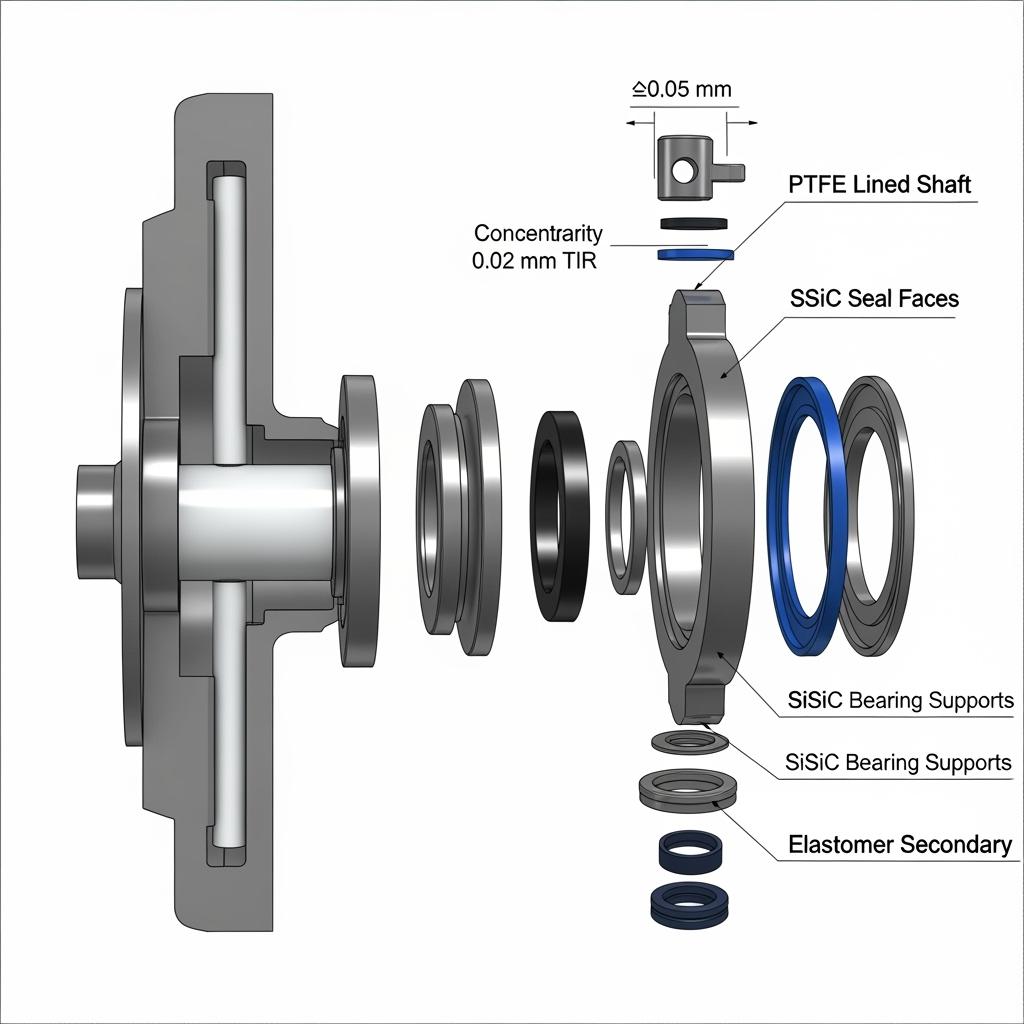

Sicarbtech’s portfolio solves the corrosion–friction–alignment triangle through a system engineered approach. The core is a custom PTFE liner—selected from virgin PTFE, glass‑filled PTFE, or proprietary modified PTFE blends—bonded or mechanically locked to the base shaft material. Surrounding that, Sicarbtech specifies complementary SiC elements: SSiC mechanical seal faces for low wear and superior thermal conductivity, RBSiC stationary rings where fracture toughness is critical, and R‑SiC or SiSiC bearing elements for rigid support in abrasive slurries. This integrated pairing decreases frictional heat at the shaft–seal interface and isolates the metallic substrate from corrosive attack.

Because Sicarbtech operates from Weifang’s SiC innovation ecosystem and is a member of the Chinese Academy of Sciences (Weifang) Innovation Park, product development draws on advanced sintering, infiltration, and recrystallization routes. That means PTFE lined shafts benefit from SiC’s elevated modulus, low thermal expansion, and chemical inertness at the interfaces that matter. For Pakistan’s textile dyeing lines, where peroxide bleaching cycles alternate with salt-heavy rinses, SSiC faces paired with PTFE lined shafts maintain sealing integrity across chemistry swings. In cement plants, RBSiC and SiSiC bearings resist slurry abrasion while the PTFE liner protects against alkali corrosion, stabilizing shaft surface finish around Ra 0.2–0.4 μm for predictable seal behavior.

Sicarbtech’s customization extends from liner thickness (typically 0.3–2.0 mm) to base materials (AISI 316L, 2205 Duplex, 17‑4PH when higher stiffness is needed), and to tolerances that match OEM fits in mixed fleets common in Pakistan. Moreover, technology transfer options allow local OEMs and maintenance contractors to adopt these solutions with on‑site training, equipment specifications, and quality documentation aligned to ISO 9001 and API 610/682 expectations.

Performance Comparison: PTFE Lined Shafts with SiC Interfaces vs Traditional Materials

Comparative Technical Performance for Pakistan’s Corrosive Duty Cycles

| Parameter | PTFE Lined Shaft + SSiC/RBSiC Interfaces | Bare Stainless Shaft (316/316L) | Duplex/Super Duplex Shaft | Hard Chrome Coated Shaft |

|---|---|---|---|---|

| Chemical resistance (HCl, H2SO4, NaOH, brine) | Excellent; PTFE inert to most chemicals; SiC interfaces resist acids/alkalis | Moderate; susceptible to chloride pitting and acid attack | Good; improved pitting resistance but not universal | Moderate; microcracks in coating expose substrate |

| Coefficient of friction (shaft–seal) | 0.05–0.10 with PTFE vs SiC faces | 0.20–0.30 metal vs carbon/SiC | 0.20–0.30 similar to 316 | 0.12–0.18 initially; rises as coating wears |

| Wear in abrasive slurries | High with SiC bearings/seal faces; liner isolated from particulates | Low; metal scoring common | Medium; better than 316 but still susceptible | Medium; coating chips under impact |

| Thermal stability (continuous) | PTFE up to ~200°C; SSiC > 1000°C at interface; system typically limited by elastomers | Up to 400°C metal, but friction heat at seals higher | Similar to stainless; better strength at heat | Coating degrades >200°C |

| Surface finish stability (Ra) over time | Stable Ra 0.2–0.4 μm with proper liner | Degrades with corrosion/pitting | Better than 316; still susceptible | Degrades as coating microcracks |

| Seal life impact | Extends mechanical seal MTBF by 1.5–3× observed in corrosive services | Baseline; frequent seal face replacement | Improved vs 316 but chemistry dependent | Variable; dependent on coating integrity |

| Energy consumption trend | Lower due to reduced friction at seal interface | Higher due to roughness-induced drag | Similar to stainless | Moderate; improves early, worsens as coating wears |

| Local compliance and leakage risk | Lower leakage risk; stable sealing improves NEQS compliance | Higher risk under acid/chloride exposure | Medium risk; chemistry-specific | Medium risk; coating failure triggers leaks |

Moreover, field data from Sicarbtech’s deployments with 19+ enterprises show maintenance intervals extended from quarterly to semi-annual in acid transfer service, with a measured 2.2% average reduction in pump power draw attributed to lower seal friction. These gains are especially relevant as Pakistan’s grid tariffs and diesel prices fluctuate, amplifying the value of every kilowatt saved.

Real‑World Applications and Success Stories in Pakistan

In a Lahore chemical plant producing hydrochloric and sulfuric acid blends for downstream textile processing, legacy shafts exhibited measurable corrosion within eight weeks, escalating seal leakage and frequent motor overload trips. Sicarbtech engineered a PTFE lined shaft with a 1.0 mm virgin PTFE liner, 316L base for compatibility, and SSiC seal faces optimized for low runout. The plant reported MTBF improvement from 4.5 months to over 11 months, a 38% reduction in seal face spend, and a 1.9% drop in average motor current. “The friction reduction was visible in the thermal camera logs; bearing housings ran cooler by 6–8°C,” the plant’s maintenance manager observed after the first two quarters of operation.

In Karachi’s oil and gas terminals, brine and H2S exposure corroded unprotected shafts, driving compliance risks. Sicarbtech deployed PTFE lined shafts paired with SiSiC stationary rings and FFKM elastomers, achieving leak rate improvements that satisfied API 682 acceptance tests and minimized fugitive emissions for insurance audits. Meanwhile, a Faisalabad textile dye house used modified PTFE liners to handle solvent-heavy dye baths; the shafts maintained a consistent Ra 0.3 μm after six months, preserving seal face integrity and reducing dye contamination in effluent streams.

Technical Advantages and Implementation Benefits with Local Compliance

The technical advantages center on chemical inertness, friction control, and dimensional stability. PTFE’s low surface energy prevents chemical adhesion, while SSiC’s thermal conductivity dissipates localized heat at the seal interface. When shafts are precision-ground and lined within tight tolerances—commonly h6/h7 fits for associated components—runout is held below 0.02 mm TIR for typical pump sizes, protecting seal faces from edge loading. Additionally, the PTFE liner acts as a sacrificial, non-reactive barrier, ensuring the metallic core retains its mechanical properties.

Implementation in Pakistan benefits from alignment with local standards and practices. Equipment is validated against ISO 5199 process pump criteria and API 610 mechanical integrity checks where applicable. Leak control solutions complement NEQS limits on emissions and effluents, while workplace exposure and safety protocols align with OSHA principles, enabling safer maintenance procedures. From an economic standpoint, procurement in PKR is stabilized through multi-quarter supply agreements, and Sicarbtech’s technology transfer allows local assembly that mitigates currency volatility.

“Material pairing is the real differentiator,” says a rotating equipment consultant who advises several major cement and chemical complexes in Punjab. “PTFE alone is not a silver bullet, and metal upgrades alone won’t stop corrosion under mixed chemistries. But PTFE lined shafts with SiC seals and bearings change the failure mode entirely.” (Reference context: rotating equipment best practices and consultant insights commonly shared in PEC and API user forums)

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive advantage is a turnkey approach that brings lab-grade material science to real production timelines. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech operates proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC, ensuring consistent microstructure, porosity control, and mechanical robustness. For PTFE lined shafts, that translates into interfaces engineered to accept SiC components without fretting or galvanic complications.

Beyond components, Sicarbtech delivers complete technology transfer packages for Pakistan’s OEMs and large end-users. These packages include bill-of-process documentation, equipment specifications for lining, bonding, and inspection stations, and training programs tailored to maintenance teams and quality staff. Factory establishment services span feasibility studies, layout design, utility mapping, and production line commissioning. Where clients seek certification, Sicarbtech assists with ISO 9001, ISO 14001, and ISO 45001 systems, and provides support for API 610/682 compliance audits.

The ongoing support model is equally robust. Application engineers collaborate on finite element checks for shaft deflection under local process loads, advise on liner thickness optimization for temperature swings in Sindh’s summers, and tune seal face material pairings for brine-acid alternation duty. Post-commissioning, Sicarbtech offers SPC-driven quality monitoring and periodic process optimization, targeting measurable KPIs like MTBF, leakage rate, and energy use per ton of throughput.

Clients across 19+ enterprises report tangible outcomes: double-digit reductions in unplanned downtime, 20–40% lower spend on seal faces and bearings, and faster maintenance windows due to cleaner disassembly and inspection of PTFE lined surfaces. These are not theoretical advantages but documented results achieved under Pakistani operating conditions and market constraints.

In‑Depth Material Options and Engineering Trade‑offs

Engineers often ask whether PTFE lined shafts are necessary when Duplex shafts seem adequate. The answer lies in service variability. Textile dye houses and chemical plants frequently change chemistries; a shaft that survives caustic may suffer in oxidizing acids. PTFE’s broad chemical resistance bridges those transitions, while SiC provides stiffness and wear resistance at critical interfaces. In cement and steel pickling lines, particulate load and acid strength fluctuate, making the low-friction, corrosion-inert lining a stabilizer for seal conditions.

Furthermore, the choice between virgin PTFE and modified blends involves subtle trade-offs. Virgin PTFE maximizes chemical resistance and low friction, whereas glass-filled PTFE increases creep resistance and dimensional stability under load but may alter tribological behavior with certain seal faces. Sicarbtech tests these combinations against SSiC and RBSiC faces in controlled rigs to select the most stable pairing for each application, then validates in the field under actual brine, acid, and temperature cycles.

Detailed Options: Materials, Thicknesses, and Tolerances

PTFE Lined Shaft Engineering Options for Pakistan’s OEM and MRO Needs

| Option | Typical Range | Engineering Considerations | Local Context Notes |

|---|---|---|---|

| Liner material | Virgin PTFE, glass‑filled PTFE, modified PTFE | Chemical spectrum vs creep resistance; seal compatibility | Textile and chemical plants often select virgin PTFE for broad resistance |

| Liner thickness | 0.3–2.0 mm | Thicker liners for aggressive acids/abrasion; impact on shaft stiffness | 0.8–1.2 mm common in Lahore chemicals; 1.5–2.0 mm in cement slurries |

| Base shaft material | 316L, 2205 Duplex, 17‑4PH | Corrosion baseline vs stiffness and load | Duplex popular where brine is present; 316L suffices when PTFE isolates media |

| Surface finish (Ra) | 0.2–0.4 μm at seal track | Seal life and friction reduction | NEQS leak control benefits from stable sealing surfaces |

| Tolerances | h6/h7 fits; TIR ≤ 0.02 mm typical | Runout control for seal face alignment | Compatible with ISO 5199/2858 equipment in local fleets |

| Seal pairing | SSiC–SSiC, SiC–carbon, SiC–PTFE interactions | Heat dissipation vs startup friction | API 682 guidance adapted for local duty cycles |

| Temperature rating | Up to ~200°C (PTFE); system limited by elastomers | Check FKM/FFKM or EPDM limits | Summer ambient adds to process heat in Sindh/Karachi |

| Compliance | ISO 9001, API 610/682 interfaces, NEQS | Documentation and traceability | Required for insurance audits and export-grade production |

Teflon vs Alternative Coatings and Lining Systems

Shaft Surface Protection Approaches Compared for Corrosive Services

| Attribute | PTFE Lined Shaft | PFA Lined Shaft | Ceramic Coating | Thermal Spray (HVOF) |

|---|---|---|---|---|

| Chemical resistance breadth | Excellent | Excellent | Good but vulnerable to HF/thermal shock | Good; depends on topcoat chemistry |

| Flexibility and crack tolerance | High; absorbs minor deflection | High | Low; brittle under impact | Medium; coating can spall |

| Surface friction | Very low | Low | Medium | Medium-low initially |

| Repairability | Replace liner segment | Similar | Difficult; often replace | Recoat required |

| Bonding/locking method | Mechanical lock or advanced bonding | Similar | Bonded ceramic | Mechanical adhesion/metallurgical |

| Cost over lifecycle | Low–Medium due to extended seal life | Medium | Medium–High | Medium; performance drifts over time |

| Fit with SiC seal/bearing interfaces | Excellent | Excellent | Good; risk of mismatch in thermal expansion | Good; watch microcrack propagation |

In Pakistan’s mixed-duty environments—where a pump may see acid on Monday and brine on Wednesday—PTFE and PFA linings outperform rigid ceramics by maintaining integrity under minor shaft deflection and thermal cycles, while SiC interfaces handle wear and heat at the hotspot.

Future Market Opportunities and 2025+ Trends

Pakistan’s industrial investment is gradually shifting from quick fixes to reliability-centered design. Three trends are especially relevant. First, environmental performance is moving from “good to have” to mandatory, with stricter enforcement of NEQS and a growing push from export buyers demanding traceable, low-leakage production equipment. Second, energy efficiency is rising in priority as tariffs fluctuate; friction reductions from PTFE lined shafts provide a persistent efficiency dividend across thousands of runtime hours. Third, localization is accelerating: OEMs and large MRO players are building capability to produce and service high-performance components domestically.

Sicarbtech’s technology transfer model aligns perfectly with these trends. By bringing proprietary R‑SiC, SSiC, RBSiC, and SiSiC processes and know‑how into local operations, Pakistani partners can shorten lead times, control costs in PKR, and enhance responsiveness. Over 2025–2027, we expect to see wider adoption of hybrid shaft systems combining PTFE liners with SiC bearing journals and integrated monitoring (vibration and temperature sensing) to predict maintenance windows. Digital twins of rotating equipment will incorporate friction coefficients and wear models specific to PTFE–SiC pairings, enabling data-driven shutdown planning.

Moreover, as pharmaceutical manufacturing expands under DRAP oversight, cleanability and chemical inertness will favor PTFE lined shafts in mixers and centrifuges, provided documentation supports validation and contamination control. In oil and gas, API-compliant assemblies with PTFE lined shafts and SiC seals will be instrumental for brine management and sour service, reducing leakage and emissions footprints.

Frequently Asked Questions

What temperatures can PTFE lined shafts handle in continuous service?

PTFE lined shafts typically handle up to around 200°C in continuous service, though the system limit often comes from elastomers in the mechanical seal. SSiC seal faces tolerate far higher temperatures, ensuring the hot zone at the interface dissipates heat effectively. For Karachi refineries and Sindh process plants with high ambient temperatures, we validate the elastomer selection to ensure reliable margins.

Are PTFE lined shafts compatible with API 610 and API 682 equipment?

Yes. Sicarbtech designs shafts to integrate with API 610 pumps and API 682 mechanical seals, maintaining runout, fits, and surface finish at the seal track. We provide drawings, QA documentation, and testing records to support audits and acceptance protocols used by local refineries and terminals.

How do PTFE lined shafts perform in abrasive cement slurries?

When paired with RBSiC or SiSiC bearing supports and appropriate seal face materials, PTFE lined shafts perform strongly. The liner protects from chemical attack while SiC components absorb abrasion. We typically recommend thicker liners (1.5–2.0 mm) and reinforced journal zones for slurry duty in cement plants around Khyber Pakhtunkhwa and Punjab.

Can we retrofit existing stainless shafts with PTFE lining?

In many cases, yes. After dimensional assessment and straightness checks, Sicarbtech can apply a mechanical lock or advanced bonding for the PTFE liner, followed by precision grinding to target Ra and TIR. Retrofit feasibility depends on remaining shaft stiffness, corrosion depth, and available seal gland geometry.

What is the expected improvement in seal life?

Field results in Pakistan’s chemical services show 1.5–3× extension in mechanical seal MTBF. Gains depend on media, solids content, and alignment. Lower friction and stable surface finish reduce face wear and heat generation, which also cuts leakage-related compliance risks under NEQS.

How do currency fluctuations affect procurement?

To mitigate PKR volatility, Sicarbtech offers phased technology transfer and local assembly options, multi-quarter price locks for critical spares, and stocking strategies aligned with seasonal demand. This approach stabilizes maintenance budgets and reduces downtime from import delays.

What quality certifications support these products?

Sicarbtech supports ISO 9001 for quality systems, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. For oil and gas, we align with API 610/682 documentation practices. Traceability covers liner material batches, SiC grade identifiers, and inspection records.

How do PTFE lined shafts help with environmental compliance?

They reduce seal leakage and fugitive emissions by maintaining smoother, inert surfaces at the seal track. Plants in Lahore and Karachi have reported easier NEQS compliance checks due to visibly lower drip and vapor release, which also improves workplace safety and audit outcomes.

What maintenance practices should we adopt?

Monitor vibration and temperature at bearings and seal chambers, inspect liner condition during planned shutdowns, and maintain clean seal flush plans. Sicarbtech provides maintenance playbooks and training for local teams, including acceptance criteria for Ra, TIR, and liner thickness.

Are there local service partners in Pakistan?

Sicarbtech collaborates with regional distributors and MRO partners for faster response in Punjab and Sindh industrial zones. For large OEMs, we implement on-site training and joint quality systems as part of technology transfer, enabling local assembly and inspection.

Making the Right Choice for Your Operations

Selecting a shaft solution isn’t just about surviving corrosion; it’s about elevating system reliability, energy performance, and compliance. PTFE lined shafts, engineered with SiC seals and bearings, reframe the failure modes that plague Pakistan’s chemical, textile, cement, and oil and gas operations. Sicarbtech’s integrated approach—rooted in advanced R‑SiC, SSiC, RBSiC, and SiSiC materials, and anchored by proven deployments across 19+ enterprises—gives you a predictable path to lower total cost of ownership and safer, cleaner production.

Get Expert Consultation and Custom Solutions

Discuss your media, temperature, solids load, and regulatory constraints with our engineers. We will evaluate your current failures, simulate friction and heat at the seal interface, and propose a PTFE lined shaft system tuned to your process. For OEMs, we can blueprint a full technology transfer, including equipment lists, SOPs, and on‑site commissioning.

Contact Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Article Metadata

Last updated: 2025-10-27

Next review: 2026-01-15

Content freshness indicators: incorporates 2025 Pakistan market outlook, NEQS compliance updates, API 610/682 alignment practices, and recent field data from local deployments.

About the Author – Mr.Leeping

With over 10 years of experience in the customized silicon nitride industry, Mr.Leeping has contributed to 100+ domestic and international projects, including silicon carbide product customization, turnkey factory solutions, training programs, and equipment design. Having authored more than 600 industry-focused articles, Mr.Leeping brings deep expertise and insights to the field.